Composite paperboard structure with excellent impact resistance

An impact-resistant, cardboard technology, applied in the direction of paper/cardboard layered products, packaging paper, flexible coverings, etc., can solve the problem of poor impact resistance, etc. Resilient, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

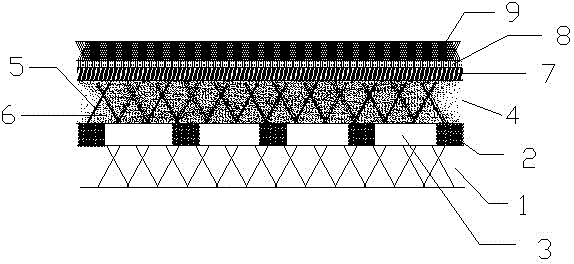

[0022] refer to figure 1 , an embodiment of a composite paperboard structure with excellent impact resistance of the present invention is proposed: the composite paperboard structure with excellent impact resistance comprises honeycomb paperboard I1, honeycomb paperboard II4 is provided on honeycomb paperboard I1, honeycomb paperboard I1 and Horizontal and parallel strip-shaped elastic gaskets 2 are arranged between the honeycomb paperboards II4, and plastic airbags 3 are arranged in the gap between two adjacent elastic gaskets 2 . The upper surface of the honeycomb paperboard II4 is provided with a reinforced fiber layer 7 , a barrier film 8 is provided on the reinforced fiber layer 7 , and a thermoplastic elastomer layer 9 is provided on the barrier film 8 . The inner surface of the honeycomb of the honeycomb paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com