Door plate edge bonding machine with cutting structure

An edge banding machine and door panel technology, which is applied in special forming/reforming machines, manufacturing tools, forming/reforming machines, etc., can solve the problem of affecting the edge banding and cutting effect of door panels, unfavorable door panel edge banding operations, and unfavorable convenience of use, etc. problem, to achieve the effect of improving convenience, improving cutting effect, and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

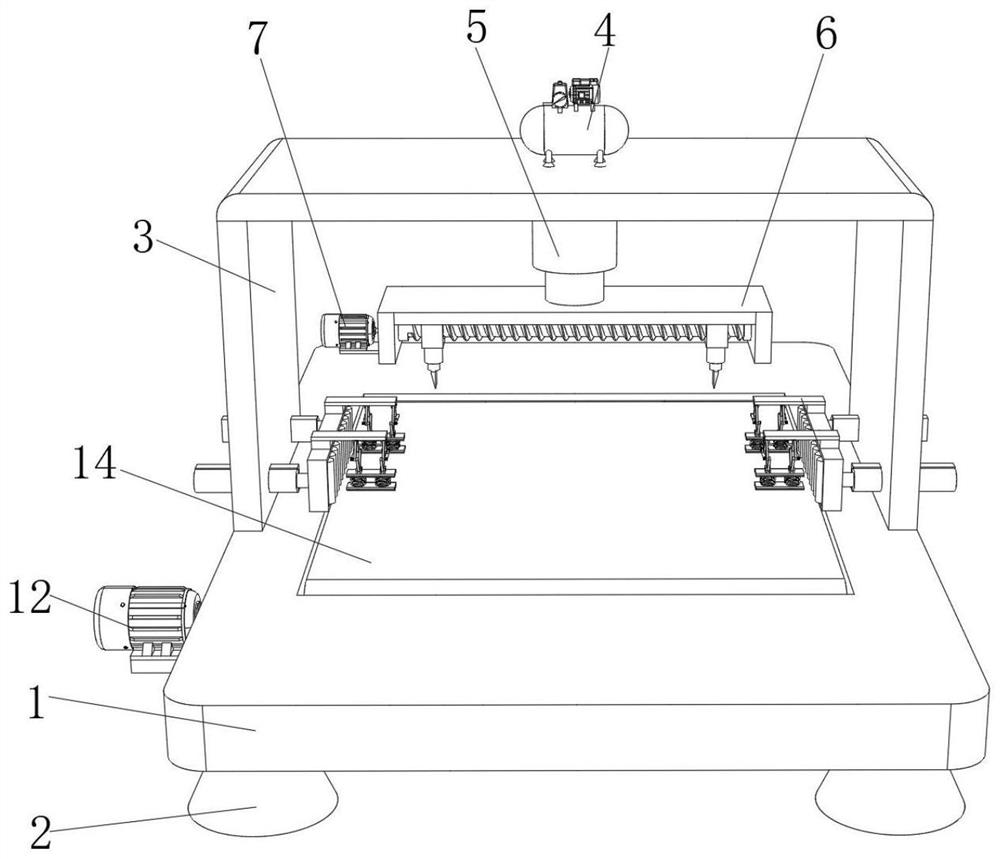

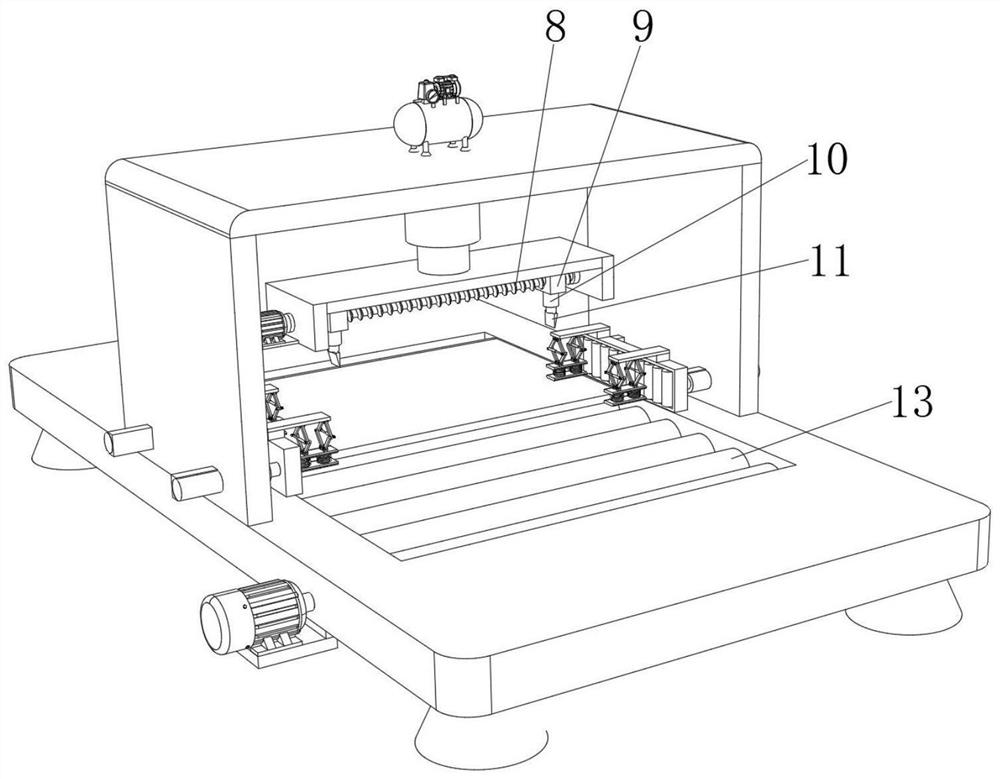

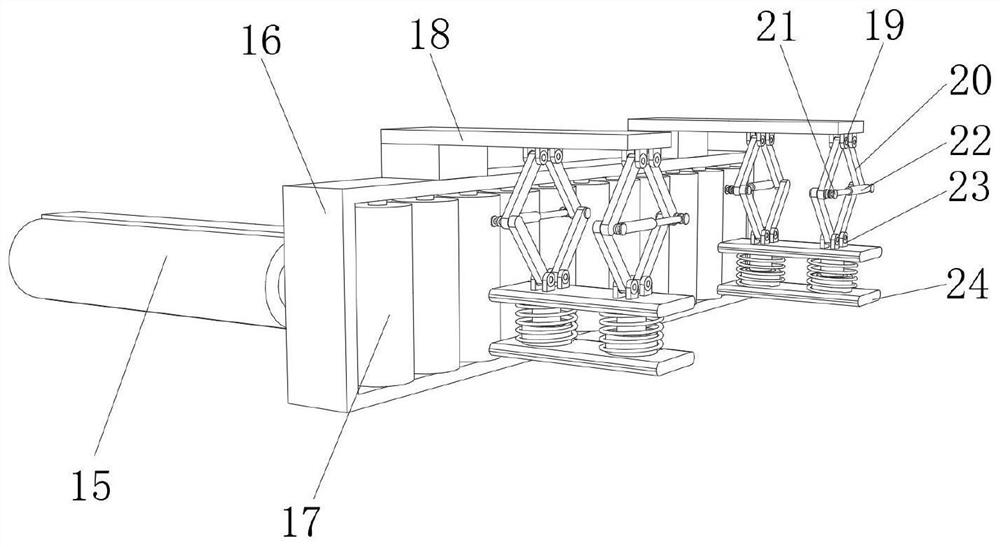

[0025] see Figure 1-3 , the present invention provides a technical solution: a door panel edge banding machine with a cutting structure, including a fixed base plate 1, a base 2 is fixedly connected to the lower surface of the fixed base plate 1, and a gantry frame is fixedly connected to the upper surface of the fixed base plate 1 3. An air pump 4 is fixedly connected to the upper surface of the gantry frame 3. The specific model of the air pump 4 is TMS750W / 850W. The inner wall of the top of the gantry frame 3 is fixedly connected to the first cylinder 5, and the lower surface of the first cylinder 5 is fixedly connected to the lifting plate 6. , the left side of the lifting plate 6 is fixedly connected with a rotating motor 7, the specific model of the rotating motor 7 is 5IK120GN-C, the output end of the rotating motor 7 is fixedly connected with an opposing screw 8, and the outer surface of the opposing screw 8 is sleeved with Moving block 9, the lower surface of moving ...

Embodiment 2

[0033] see Figure 1-2 with Figure 4 , the present invention provides a technical solution: a door panel edge banding machine with a cutting structure, including a fixed base plate 1, a base 2 is fixedly connected to the lower surface of the fixed base plate 1, and a gantry frame is fixedly connected to the upper surface of the fixed base plate 1 3. An air pump 4 is fixedly connected to the upper surface of the gantry frame 3. The specific model of the air pump 4 is TMS750W / 850W. The inner wall of the top of the gantry frame 3 is fixedly connected to the first cylinder 5, and the lower surface of the first cylinder 5 is fixedly connected to the lifting plate 6. , the left side of the lifting plate 6 is fixedly connected with a rotating motor 7, the specific model of the rotating motor 7 is 5IK120GN-C, the output end of the rotating motor 7 is fixedly connected with an opposing screw 8, and the outer surface of the opposing screw 8 is sleeved with Moving block 9, the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com