Conveying system capable of removing lodging bottles

A transmission system and bottle technology, applied in the direction of packaging bottles, transportation and packaging, packaging, etc., can solve the problems of affecting packing, bottle dumping, etc., and achieve the effect of convenient use, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

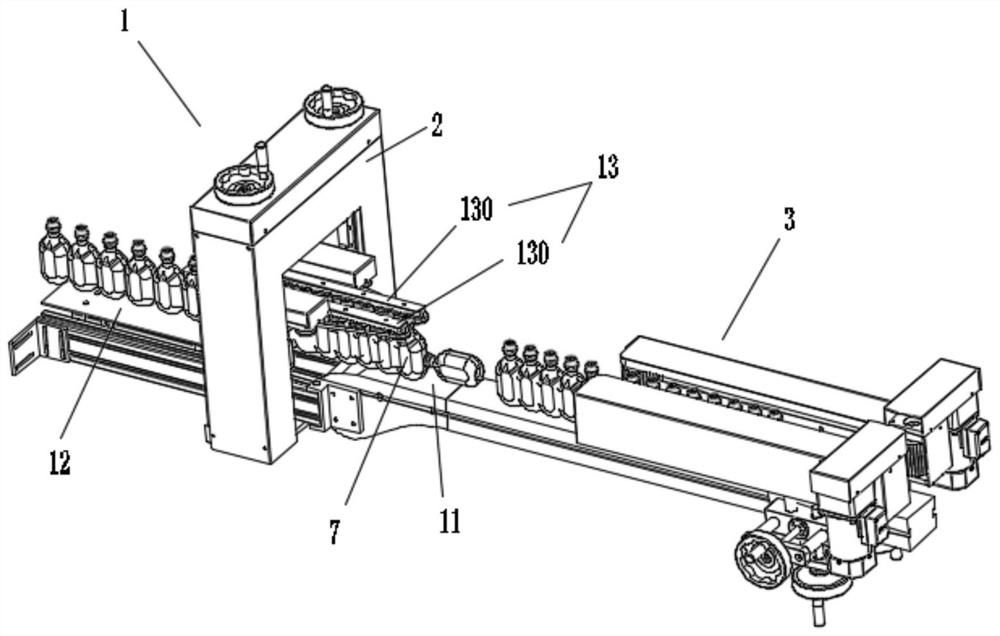

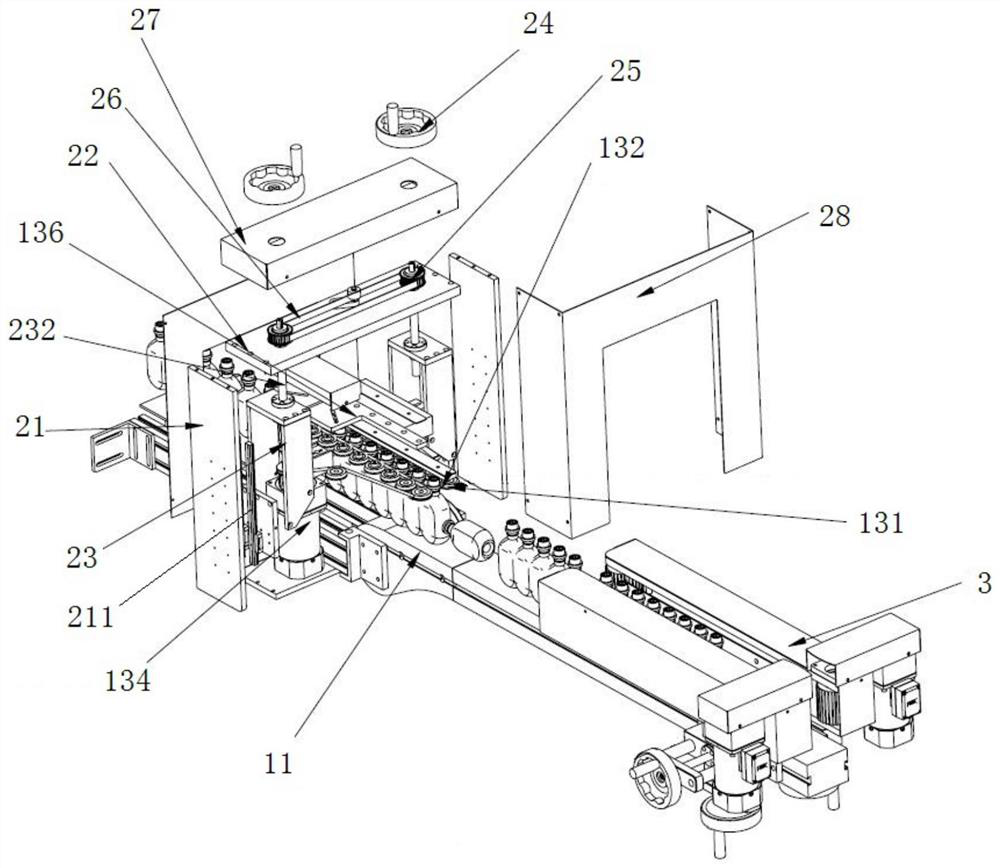

[0037] Such as figure 1 , 2 As shown, the transmission system for rejecting fallen bottles disclosed in the present invention includes a fallen bottle rejecting mechanism 1 and a bottle unscrambling system. The inverted bottle rejecting mechanism 1 includes a first conveying device 11 , a second conveying device 12 and a first clamping bottle feeding conveyor 13 .

[0038] The first conveying device 11 and the second conveying device 12 are arranged at intervals, and the first clamping bottle infeed conveyor 13 is used to transfer the articles on the first conveying device 11 to the second conveying device 12 .

[0039] In this embodiment, the first conveying device 11 and the second conveying device 12 convey horizontally along the same direction.

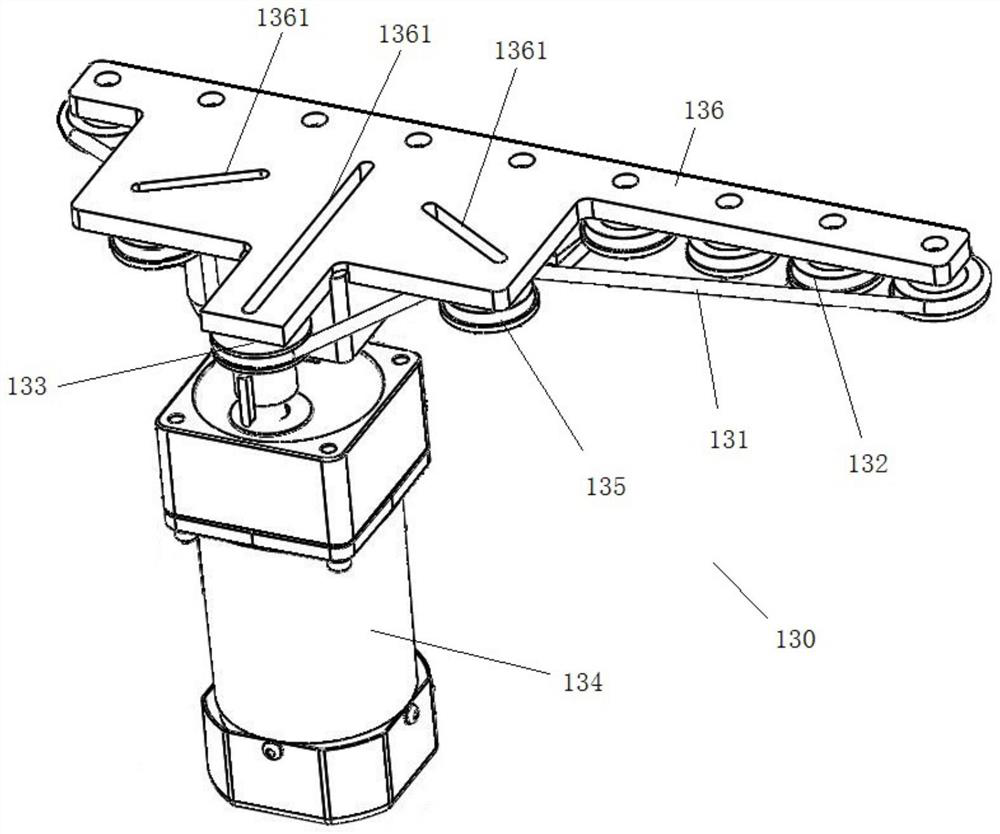

[0040] Such as figure 1 , 2 , 3, the first clip-type bottle-feeding conveyor 13 includes two bottle-feeding belt devices 130 arranged left and right. The bottle-feeding transmission belt device 130 comprises a bottle-feeding ...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that: Figure 9 As shown, in this embodiment, the horizontal screw rods 42 of the two left and right adjustment mechanisms 4 are replaced by a double-threaded screw rod 6 , and the double-threaded screw rod 6 passes through the frame of the first transmission device 11 . The double-thread screw rod 6 has two threaded sections 61 in opposite directions, and the left and right horizontal sliders 41 are threadedly engaged with one of the threaded sections 61 respectively. The left and right adjustment handwheels 45 of an end of any adjustment double-thread screw mandrel 6 can make two horizontal sliders 41 move horizontally towards or against each other.

[0074] The height adjustment and the left and right adjustments in Embodiment 1 and Embodiment 2 all rely on manual adjustment. In other embodiments, automatic adjustment may be used, for example, the automatic adjustment may be performed by using a motor to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com