Assembly type heat preservation shed for winter construction unloading point and assembly method thereof

A prefabricated, thermal insulation shed technology, applied in the processing of building materials, special buildings, ladders, etc., can solve the problems of pouring concrete, failure to pour, temperature loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

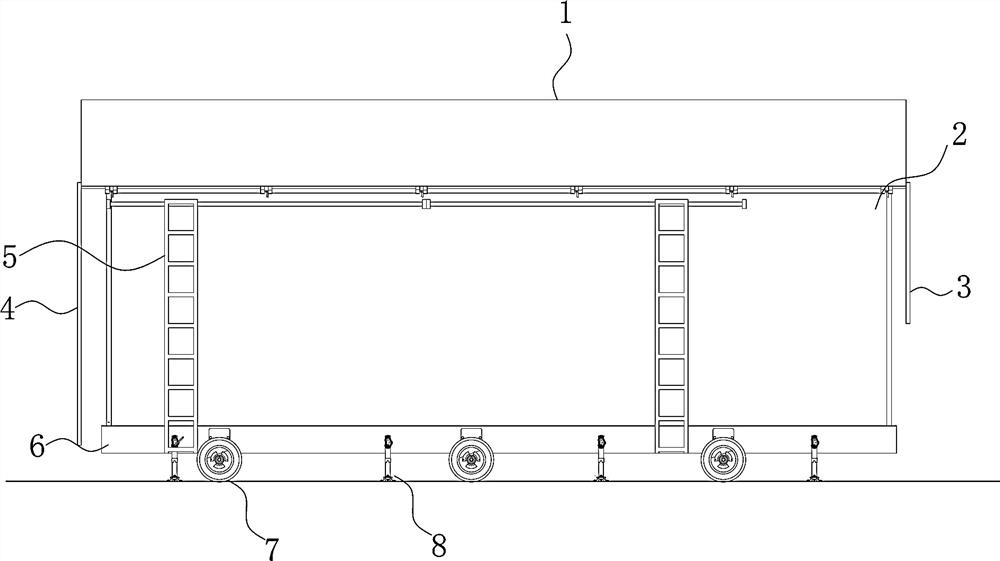

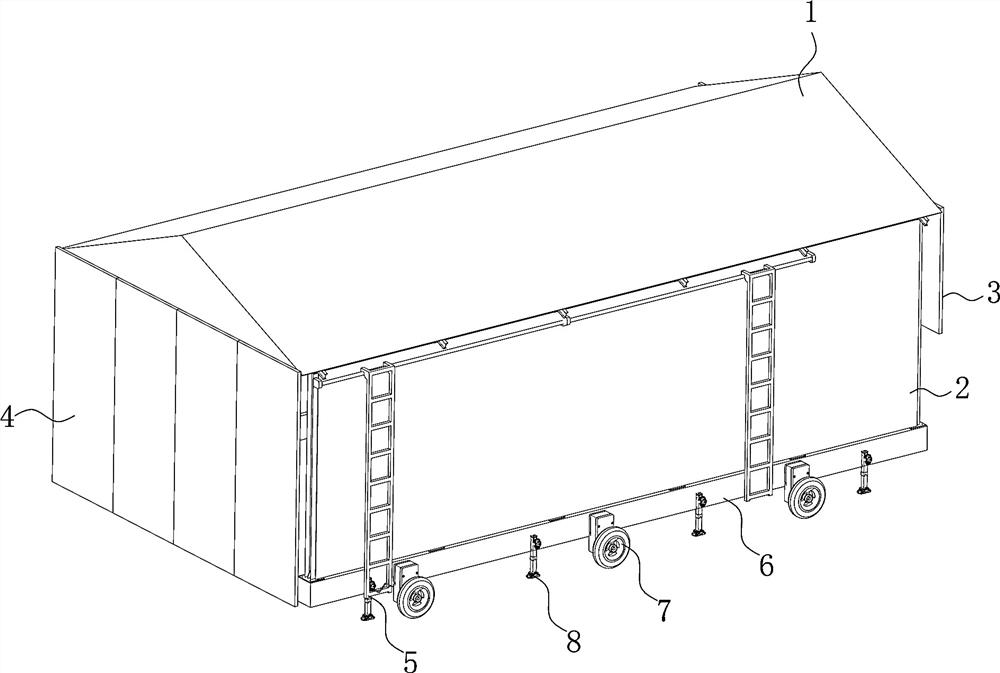

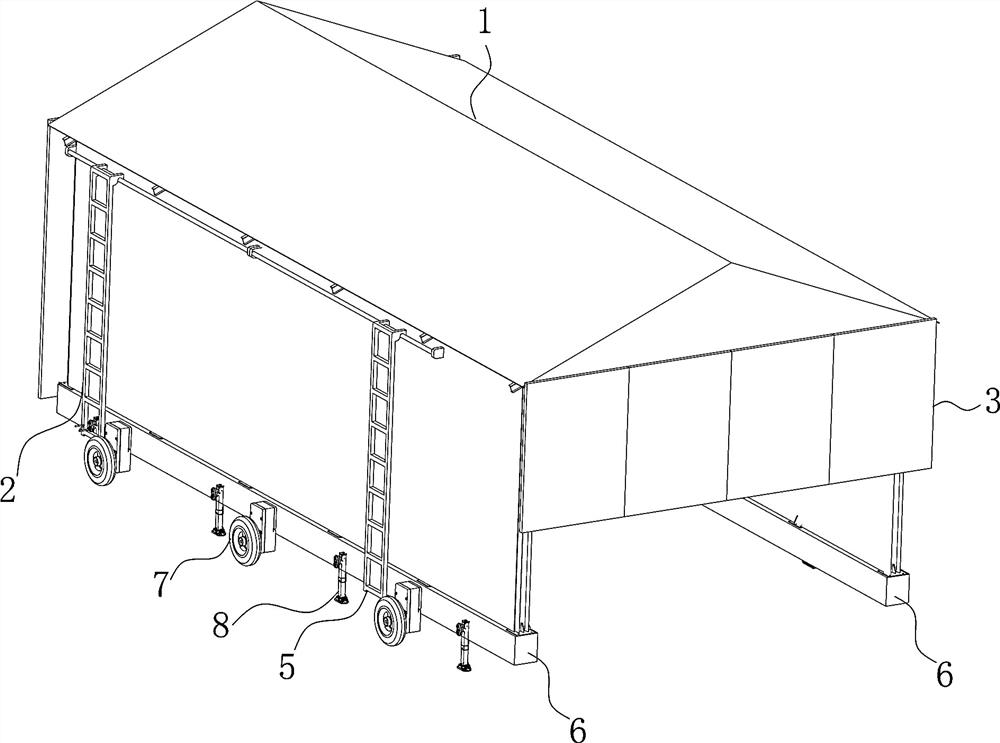

[0042]Such asFigure 1 ~ 11 As shown, a winter construction unloading point assembly thermal latent joint, including at least two parallel coupling base 6, a counter base 6, a side frame 10, two side frames 10 through the top frame 9 Connect, the side frame 10 and the top frame 9 form a shang, the top frame 9 is provided with a ceiling 1, and a side heat insulating plate 2 is provided on both sides of the side frame 10, a side heat insulating plate 2, two heat insulating plate 2. There is a thermal insulation cotton, the whole is mechanically connected, convenient to safety, can be installed when there is a harsh weather such as winter. Usually disassemble. Savings.

[0043]A plurality of supporting devices 8 are provided below the load base 6, and a plurality of drive mechanisms 7 are provided on the side of the support device 8. The support device 8 is an adjustable structure, which is convenient to adjust the level of the shack and ensure the level of insulation shed.

[0044]Preferably...

Embodiment 2

[0052]Further explanation in conjunction with Example 1, such asFigure 1-11The structure shown, first assemble multiple brackets to the side frame 10 and the top frame 9.

[0053]The two counterweight base 6 mount the connecting seat 11 on the top of the side frame 10 on both sides, and then mounted on the connecting seat 11, and spliced into a skeleton shack.

[0054]After the skeleton shack is formed, the support device 8 is mounted on the counter base 6, and the rotary driving hand supports 801 to support the entire skeleton shack, adjust the skeleton shalar, so that the skeleton shack maintains the horizontal direction. When using, in planning unloading points, first flat, in place, and install the horizontal base according to the order of the order.

[0055]When using, in planning unloading points, first flat, directly hoisting, load the loaded load box directly. The front and rear entrances are used to hang the insulation cotton according to the vehicle and the insulated shed.

[0056]I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com