Self-rotating type pneumatic down-the-hole hammer

A down-the-hole hammer and spin-type technology, which is applied to the driving device for drilling in the wellbore, drilling equipment, wellbore/well components, etc., can solve the problem of aggravating the rapid wear of the impact hammer, reducing the transmission efficiency, and affecting the drilling efficiency, etc. problems, achieve the effect of reducing the wear of the impact hammer, shortening the length of the drill pipe, and improving the drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

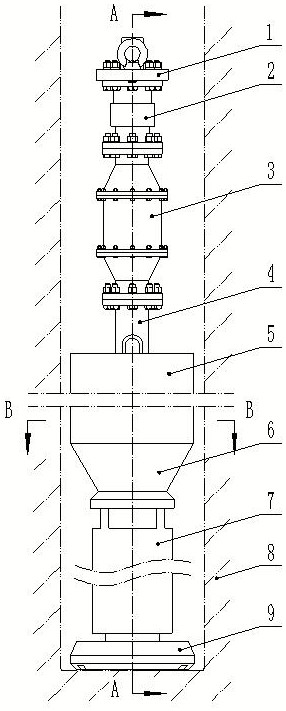

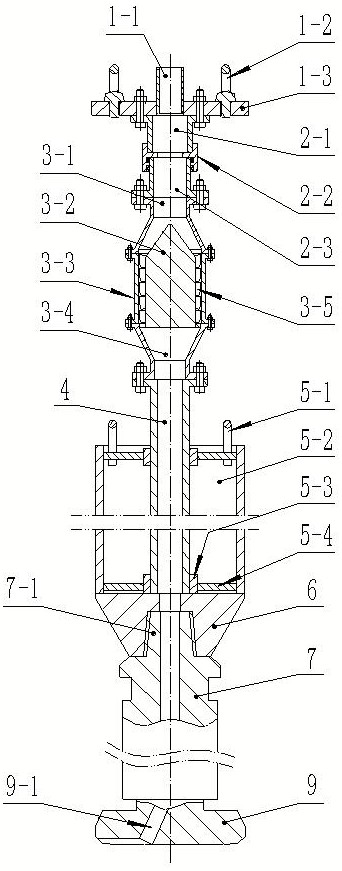

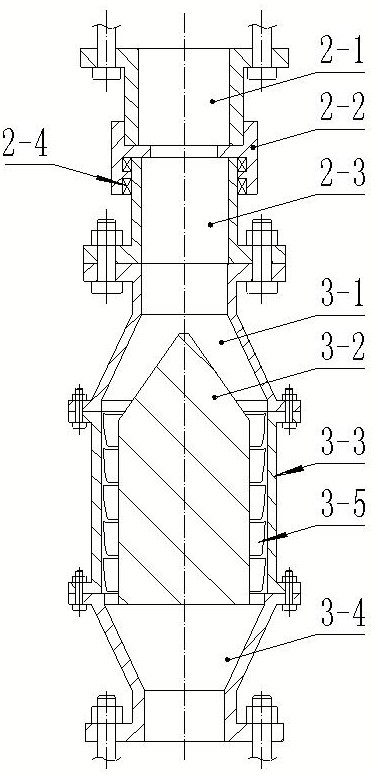

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as Figure 1-5 As shown: the pneumatic down-the-hole hammer is composed of an impactor 7 and an impact hammer 9 that is slidingly connected to the impactor through a spline (not shown in the figure). The rotary device drives the pneumatic down-the-hole hammer through the drill rod 4 to perform rotary motion. The rotating device is composed of a support plate 1, a rotating joint 2 and a screw pneumatic device 3 fixedly connected sequentially from top to bottom, wherein:

[0025] The support plate 1 is composed of an air inlet joint 1-1 fixed on the support plate 1-3 and two lifting lugs 1-2 for connecting the lifting wires (not shown in the figure). The hoisting steel rope can make the present invention vertically move up and down under the drive of the hoist, so that the drilling depth is not limited by the length of the drill pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com