Rock-soil layer anti-backward anchor rod for mining

It is a technology of anti-regression and rock-soil layer, which is applied in mining equipment, bolt installation, earthwork drilling and mining, etc. It can solve problems such as easy loosening of the anchor head, falling off of the cement cohesive layer, retreating into the rock layer, etc., so as to prevent the anchor The effect of falling back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

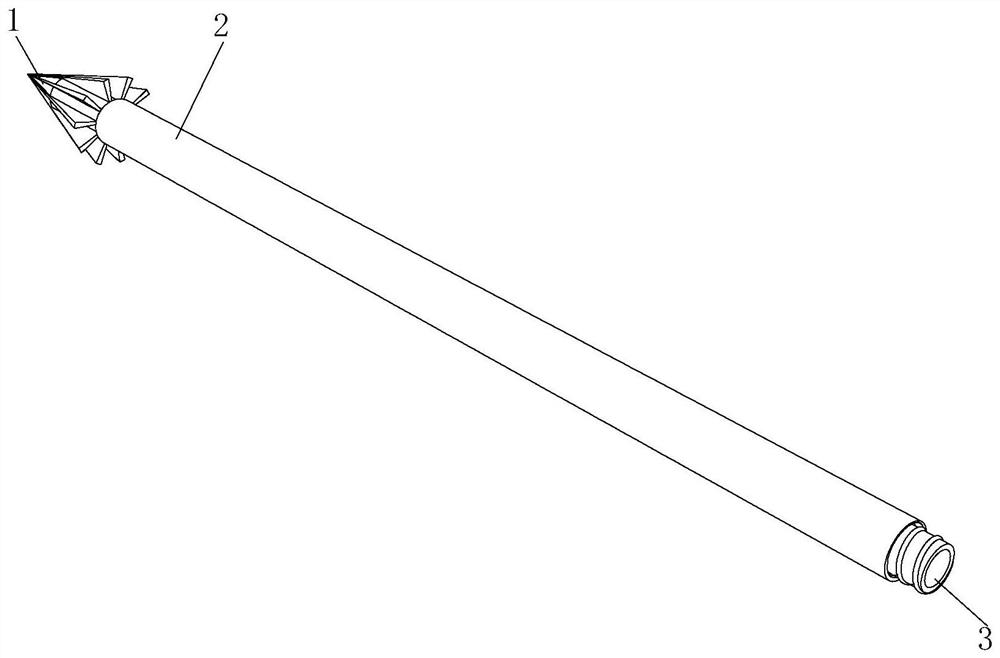

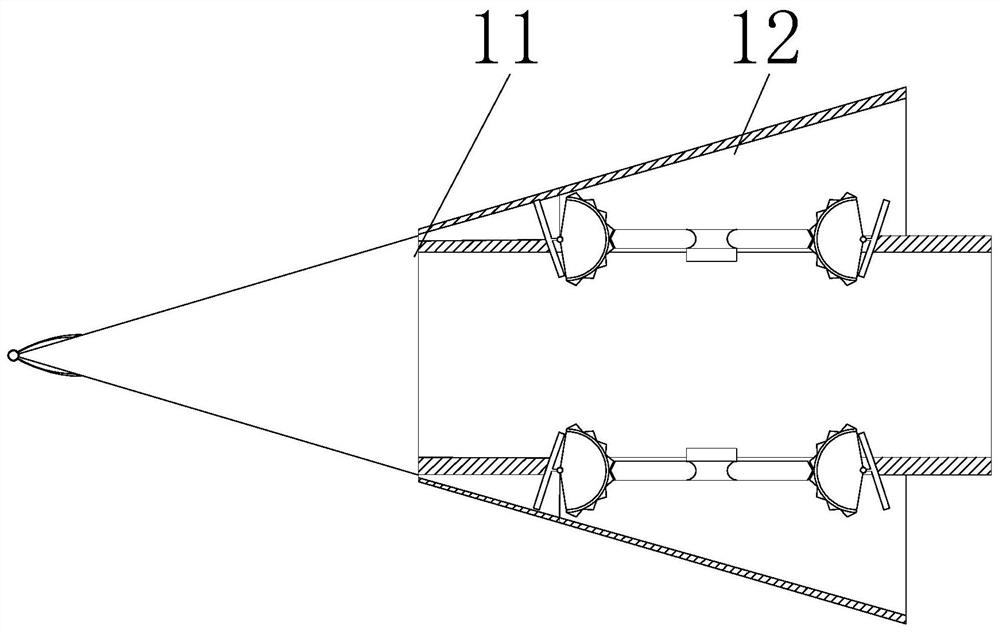

[0026] Such as Figure 1-Figure 6 As shown, the present invention provides a rock-soil layer anti-regression bolt for mining, comprising an anchor head 1, a rod body 2 and a bolt joint 3, the bottom of the anchor head 1 is movably connected with the top of the rod body 2, and the bottom of the rod body 2 is connected to the The top of the anchor joint 3 is threaded, the anchor head 1 includes a front drill bit 11 and a connection head 12, the bottom of the front drill bit 11 is fixedly connected with the top of the connection head 12, the front drill bit 11 includes a drill shell 111 and a cover plate 112, and the connection head 12 It includes a drill plate 121 , a hollow pipe 122 , a push block 123 , a hose 124 and a rotating gear 125 .

[0027] In this embodiment, a hollow anchor head 1 is used, and the anchor head 1 is divided into a front drill bit 11 and a connecting head 12, so that when the anchor rod is drilled into the rock and soil layer, it is convenient to inject ...

Embodiment 2

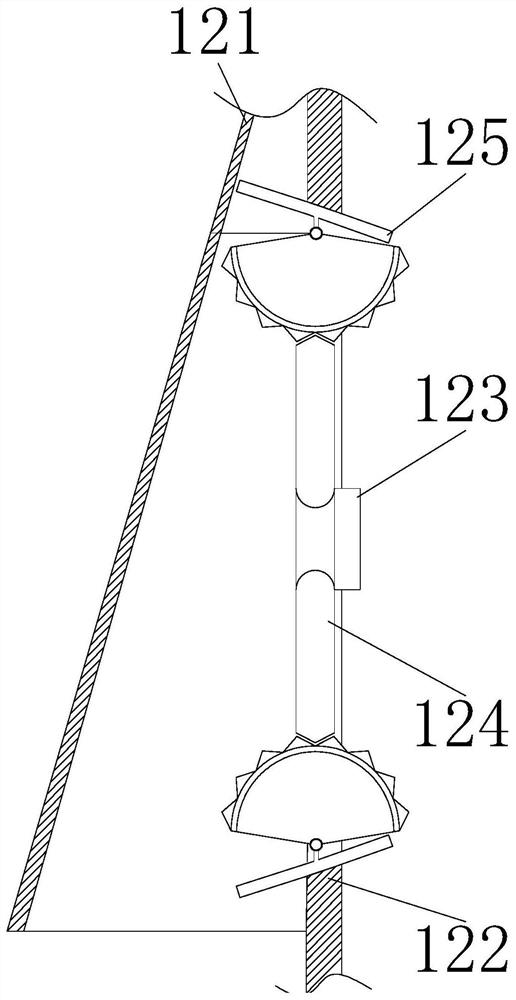

[0031] Such as Figure 3-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the bottom of the rotating gear 125 is fixedly connected to the top of the hose 124, the right end of the hose 124 is fixedly connected to the left side of the push block 123, and the soft The tube 124 includes a hose shell b1, a hollow tube b2 and a hollow tip b3, and the right side of the hose shell b1 is provided with a through hole, and the two ends of the inner wall of the hose shell b1 are provided with a card slot, and the inner wall of the card slot and the One end of the hollow tube b2 is clamped, and the outer wall of the hollow tube b2 is uniformly provided with several hollow pointed ends b3.

[0032] In this embodiment, the material of the hose 124 is a soft material, and the right side of the hose 124 is fixedly connected with a push block 123, wherein when cement is injected into the anchor rod, the cement is squeezed and pushed inside the holl...

Embodiment 3

[0034] Such as Figure 3-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the cover plate 112 includes a rotating part d1 and a baffle plate d2, and slideways c6 are provided on both sides of the inner wall of the drill housing 111 , and both sides of the inner wall of the drill shell 111 are provided with arc-shaped grooves, and the arc-shaped grooves are located at the bottom of the slideway c6, the inner wall of the drill shell 111 is fixedly connected with a support spring c1, and the top of the support spring c1 is fixedly connected with a rotating ball c2, The bottom of the rotating ball c2 is rotatably connected with the inner wall of the drill housing 111, the top of the rotating ball c2 is fixedly connected with a compression spring c4, the inner wall of the slideway c6 is slidably connected with a hook tube c5, and the bottom of the hook tube c5 is fixedly connected with a pressure plate c3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com