Wind driven generator

A technology for wind turbines and air inlet pipes, which is applied in the directions of wind turbines, wind turbine combinations, and wind power generation, can solve problems such as inability to protect, low power generation efficiency, detection, etc., so as to improve power generation efficiency and quality, and facilitate installation and disassembly. , the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

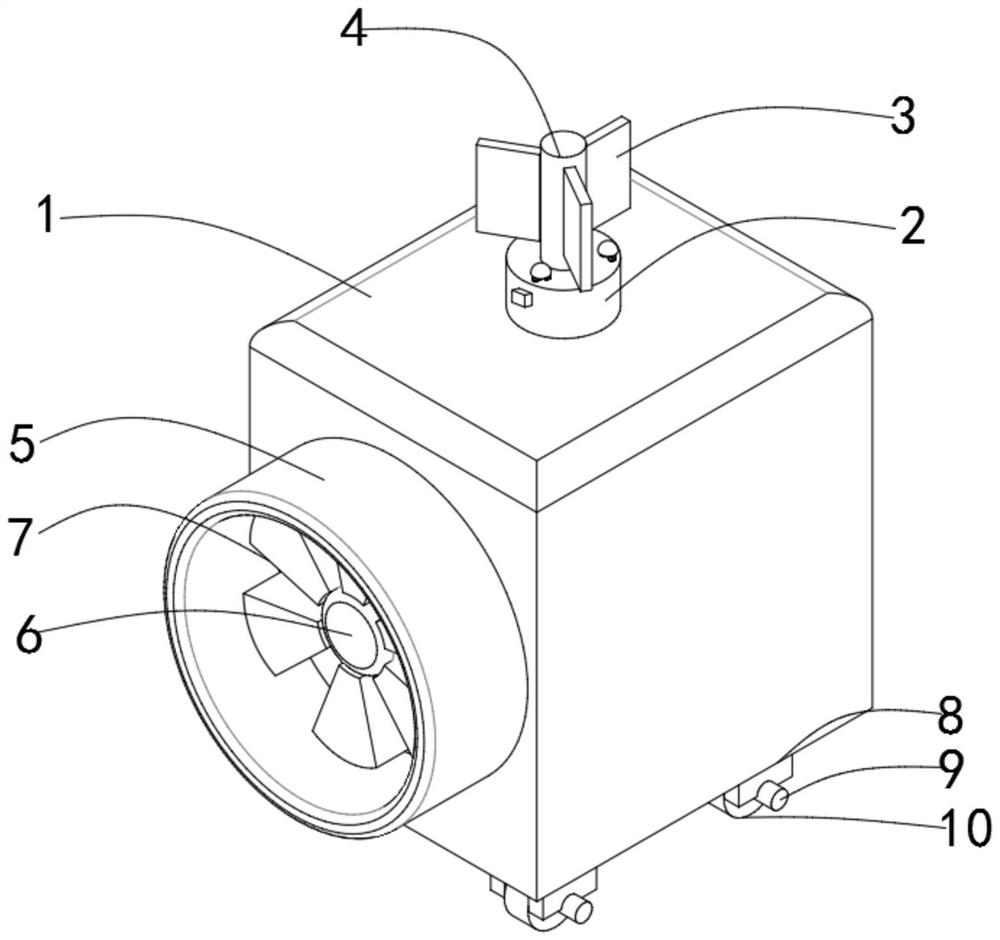

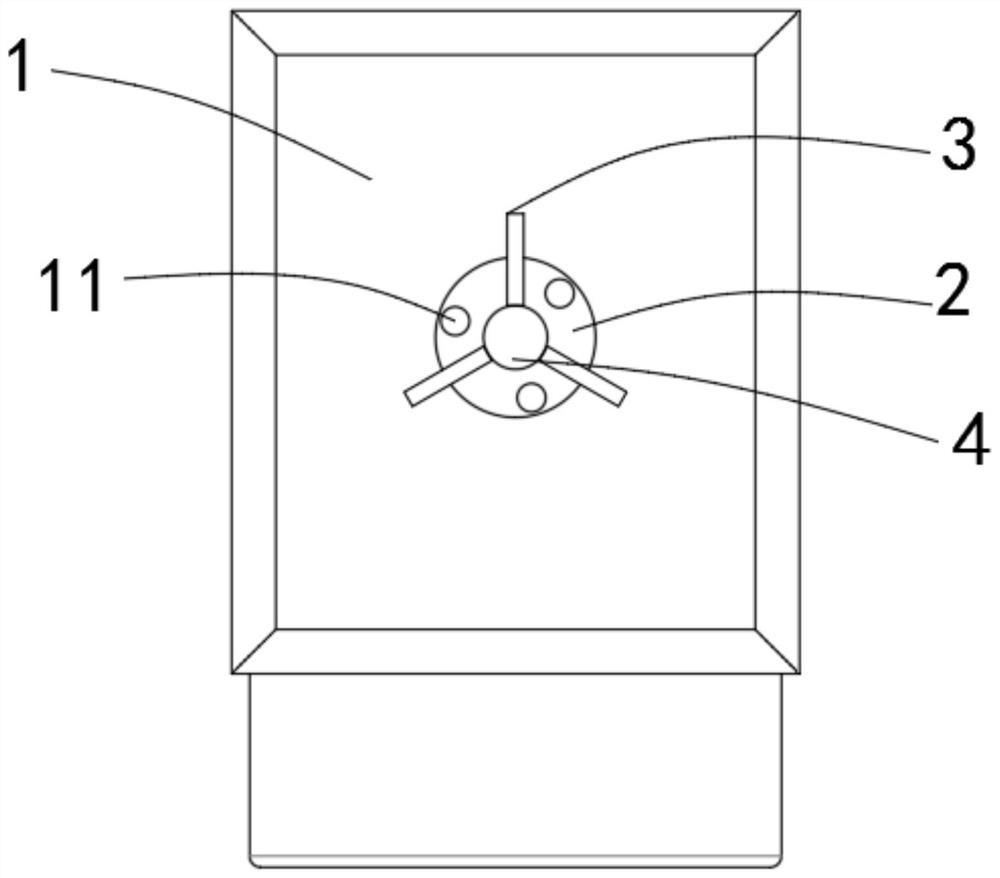

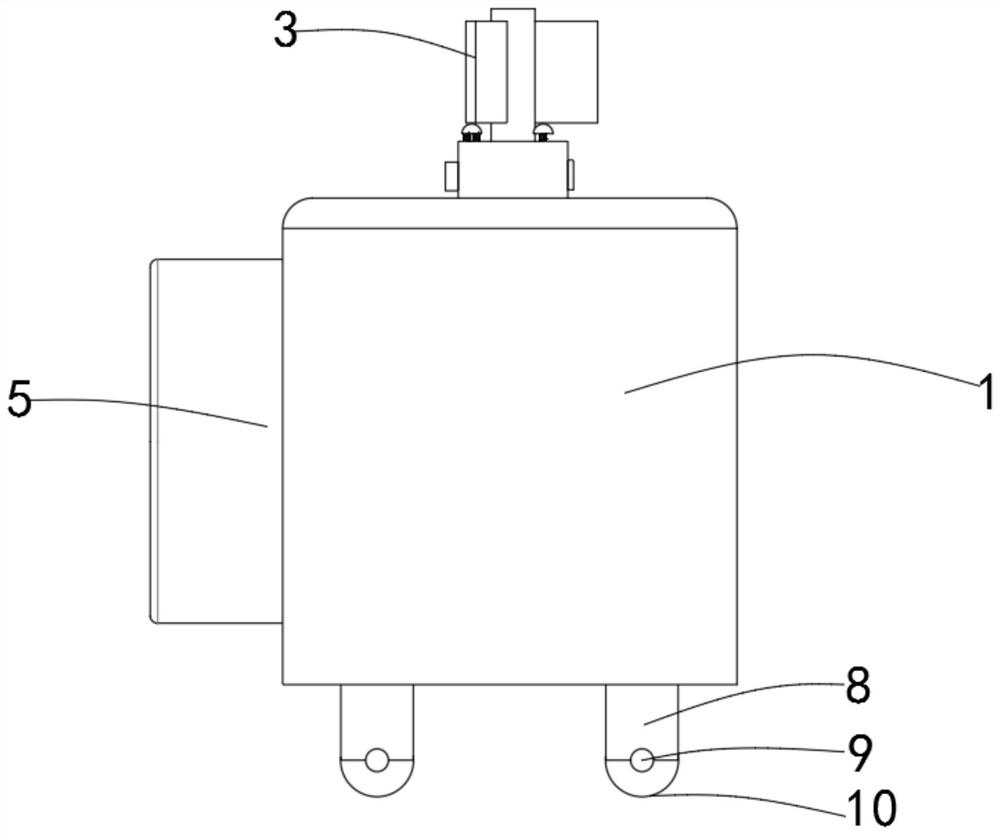

[0033] The following is a specific method of using a wind-driven generator: when using the present invention, first move the wind-powered generating box 1 to a corresponding position, detect the wind direction through the wind direction detection board 3, and then direct the air inlet duct 5 to the corresponding position, and then fix its position through the brake block 9, when the wind is too strong, the hydraulic device 16 will stretch the moving rod 17, so that the mounting plate 21 will slide, so that the second mounting block 23 will squeeze the first mounting block 15, making the extruding block 14 move, extruding the extruding ring 26, through the friction force between the two to make the fan rotating shaft 6 decelerate and rotate, and play a protective effect;

Embodiment 2

[0035] It should be further explained that when the wind force detection is completed, the wind force detection board 3 needs to be disassembled, and the first clamping block 29 is squeezed downward by pressing the pressing plate 11, and the second clamping block 31 is completely squeezed to the limit. In the position slot 36, the installation slider 33 can be pulled out of the first installation slot 27 by pressing the pressing plate 34 again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com