Main bearing mechanism and compressor

A main bearing and compressor technology, applied in the field of compressors, can solve the problems of high main bearing height, insufficient lubrication, etc., achieve the effect of improving lubrication efficiency, solving insufficient lubrication, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

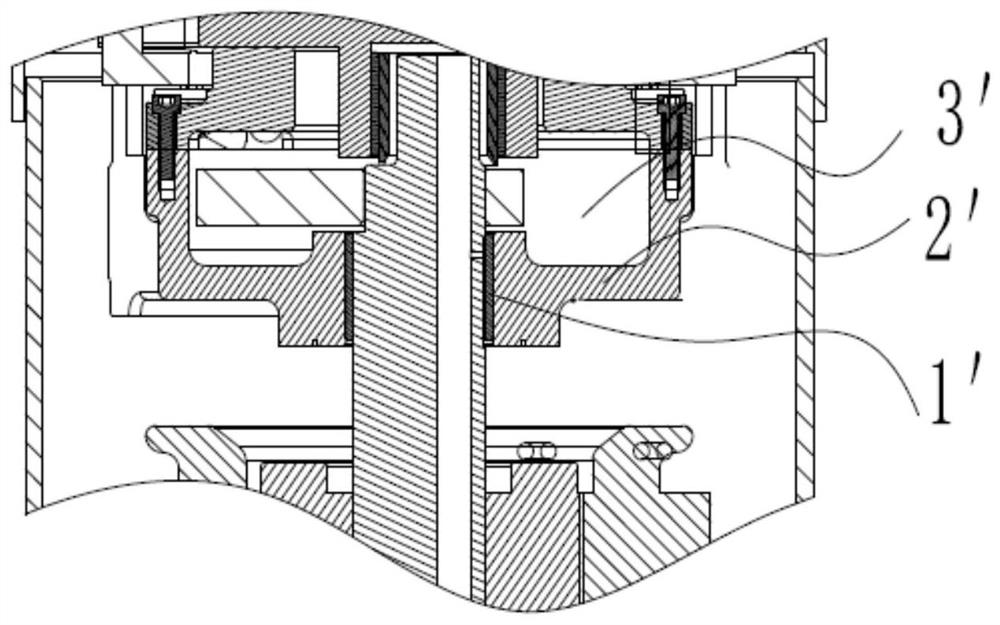

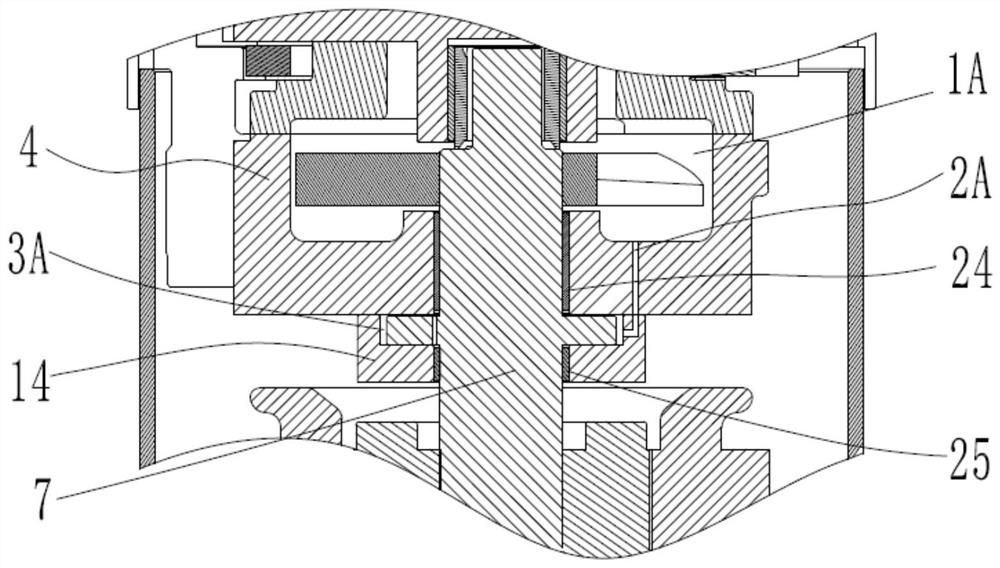

[0029] This embodiment describes the main bearing mechanism of the present invention in detail.

[0030] The main bearing mechanism of this embodiment includes a bearing assembly and an oil pool assembly. Among them, the bearing assembly includes at least two sections of main bearings, and at least two sections of main bearings are separated; the oil pool assembly includes at least two oil pools, and the number of oil pools is not less than the number of main bearings, and each section of main bearing The bearings can be lubricated by lubricating oil in at least one oil sump. Preferably, each section of the main bearing can be lubricated by lubricating oil in one oil pool, or lubricated by lubricating oil in two or more oil pools.

[0031] The main bearing mechanism of this embodiment includes a bearing assembly and an oil pool assembly, wherein the bearing assembly includes at least two sections of main bearings, and at least two sections of main bearings are arranged separa...

Embodiment 2

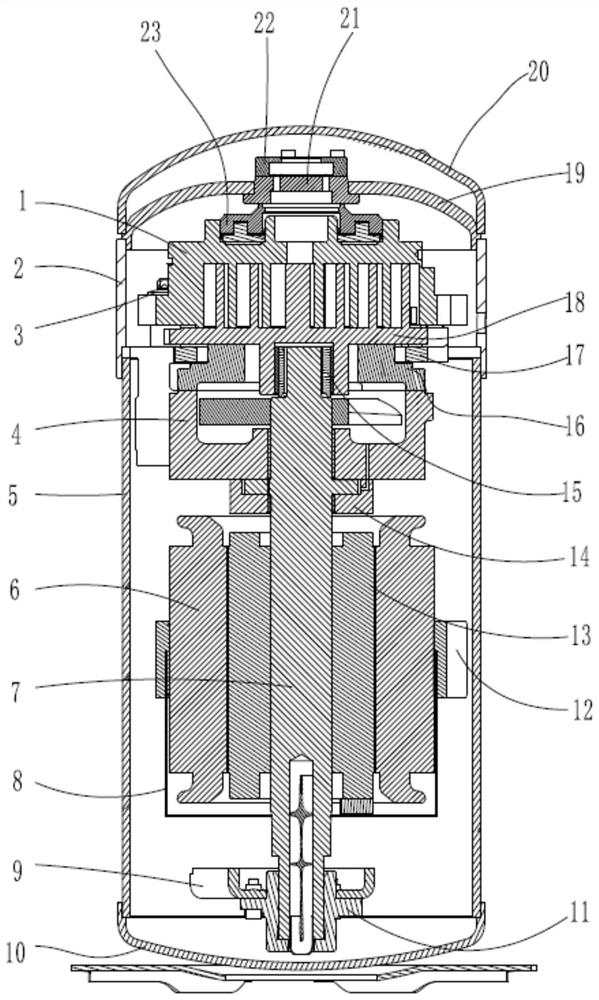

[0041] The compressor of this embodiment includes the main bearing mechanism of any technical solution in Embodiment 1. Preferably, the compressor in this embodiment is a scroll compressor. More preferably, the compressor in this embodiment is a scroll compressor used in air conditioners or heat pumps.

[0042] The remaining parts of the scroll compressor are the same as the existing scroll compressor. Such as figure 2 As shown, the scroll compressor of this embodiment is mainly composed of a motor 6, an upper bracket 4, a lower bracket 11, a fixed scroll 1, a movable scroll 18, an Oldham slip ring 17, a crankshaft 7, and the like. The movable scroll 18 and the fixed scroll 1 are installed opposite to each other on the upper bracket 4 with a phase angle difference of 180°. The movable scroll 18 moves under the drive of the crankshaft 7 and meshes with the fixed scroll 1 to form a series of mutually isolated and continuously changing volumes. The crescent-shaped airtight ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com