Installation process of fireproof smoke exhaust valve and fireproof smoke exhaust valve

An installation process and technology for smoke exhaust valves, which are applied in valve devices, balance valves, safety valves, etc., can solve the problem of not publicly installing fire control valves, etc., and achieve convenient installation of fire exhaust valves, increase air humidity, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

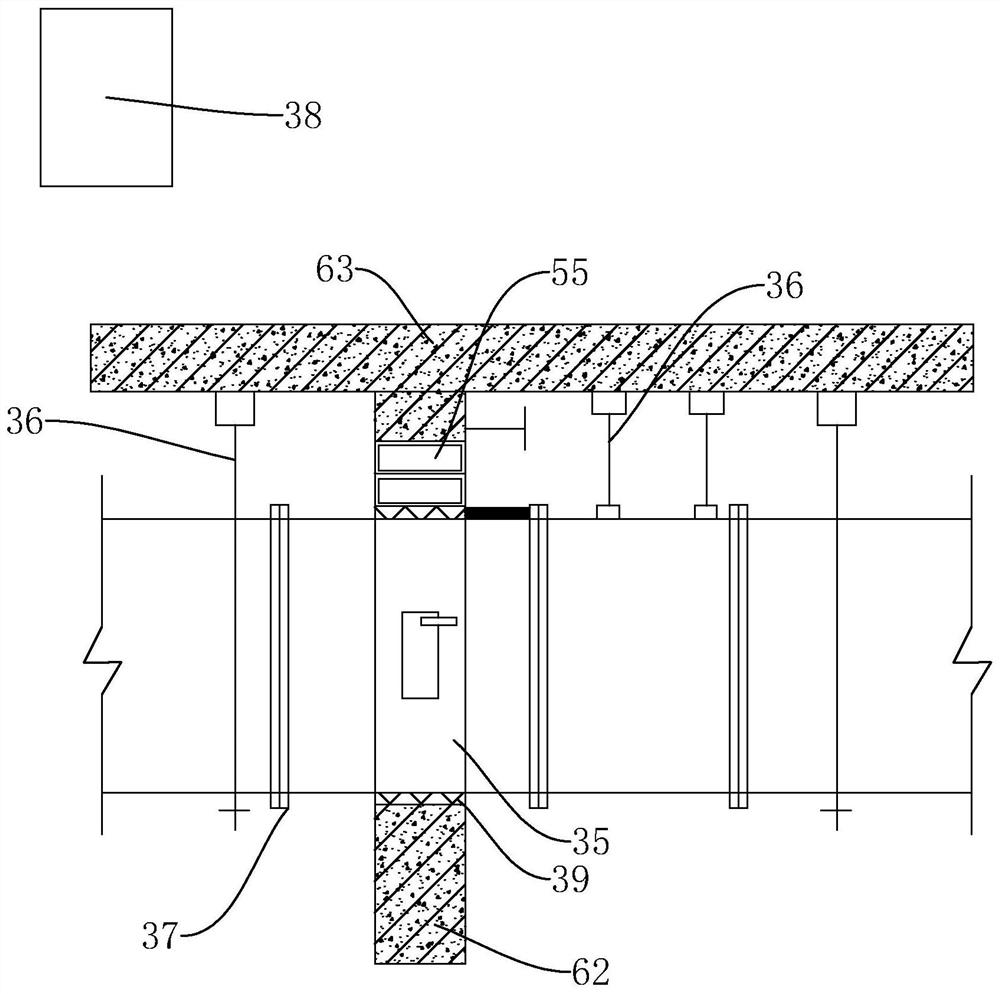

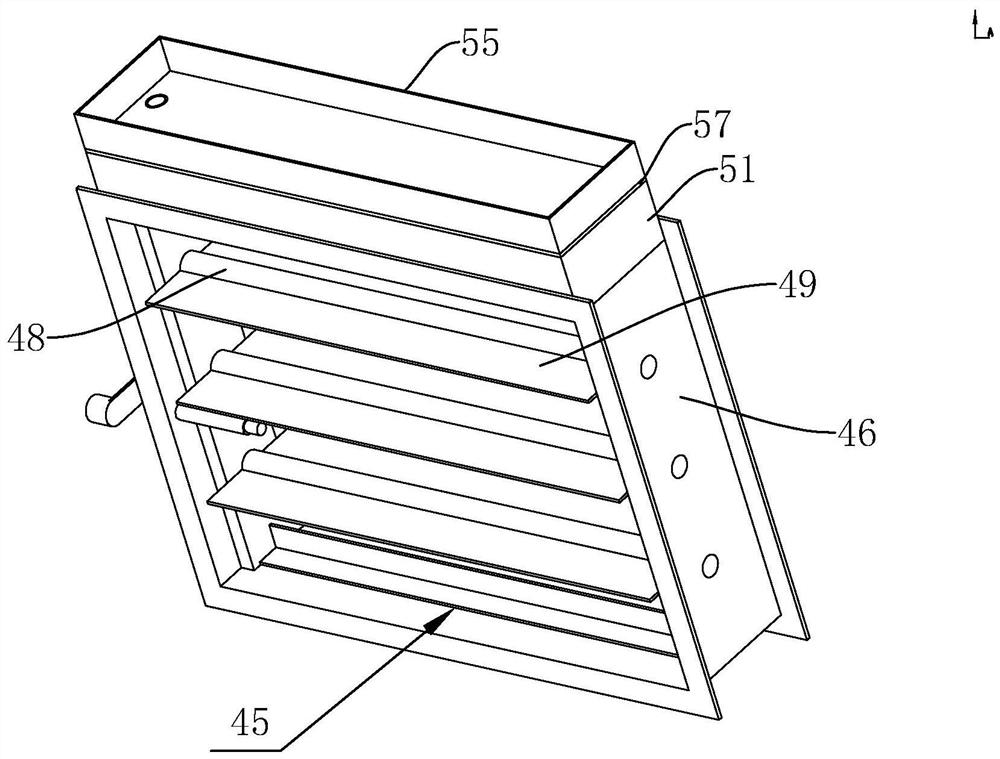

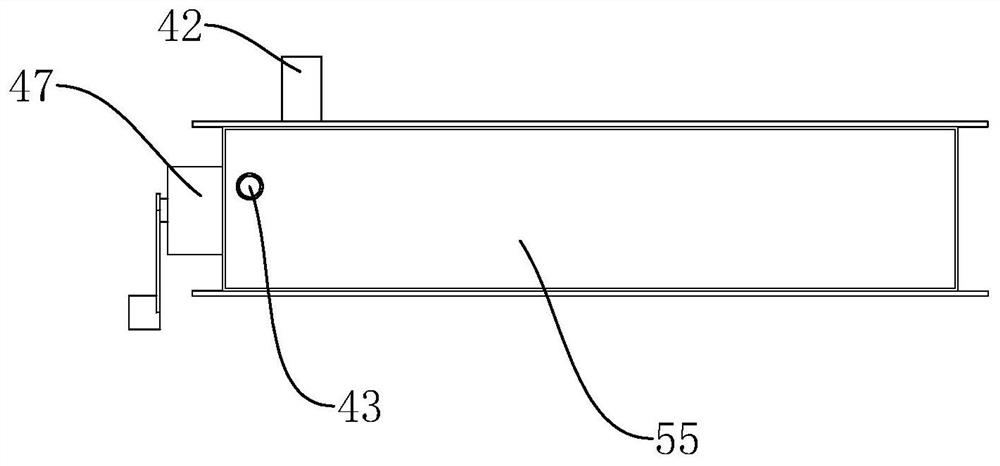

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0050] Such as figure 2 and image 3 As shown, the present application provides a fire and smoke exhaust valve 35, including a valve body 45, and the valve body 45 includes a frame 46, a controller 47, and a valve leaf shaft 48, and a fire valve leaf 49 is installed on the valve leaf shaft 48, and the valve body 45 A rolling shutter smoke prevention assembly 40 and a water flow transition assembly 41 are installed sequentially from bottom to top. Preferably, a fireproof heat shield 57 is connected between the rolling shutter smoke prevention component 40 and the water flow transition component 41 to prevent the water flow transition component 41 from being damaged due to excessive temperature.

[0051] This application mainly aims at the problem that the fire and smoke exhaust valve 35 before improvement is weak in fire and smoke prevention, and provides a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com