Ultrahigh-pressure exhaust valve

A technology of ultra-high pressure and exhaust valves, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as seal failure, seal damage, and difficulty in opening again, so as to ensure seal reliability and prevent Excessive compression, which facilitates the effect of opening the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

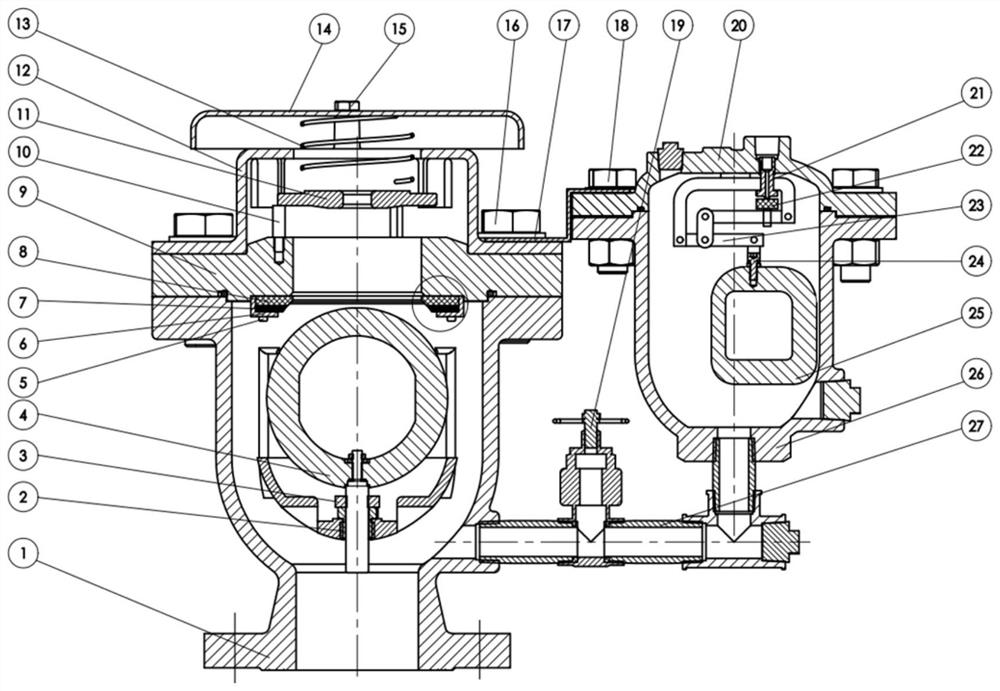

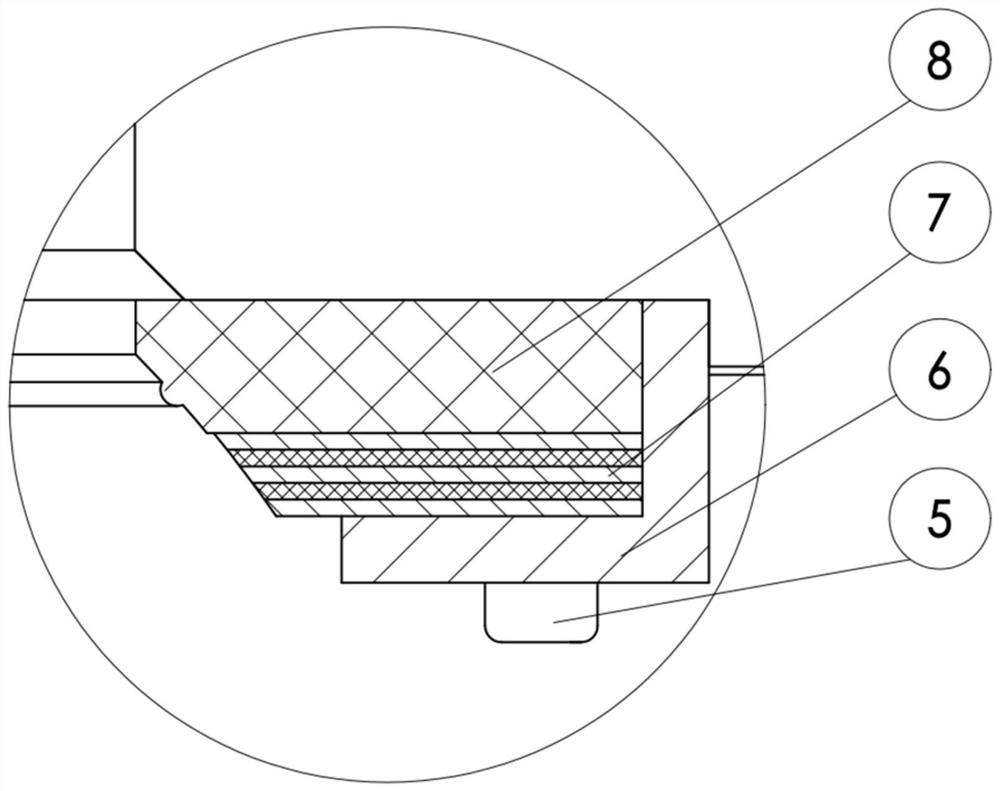

[0035] like figure 1 and 2 As shown, the present invention provides an ultra-high pressure exhaust valve, which is suitable for ultra-high pressure environments with a pressure rating of PN63 and above. The exhaust valve is mainly composed of a main valve and a trace exhaust valve group. , the main valve is used to realize a large amount of low-pressure exhaust and a large amount of air intake, and the micro-exhaust valve group is used to realize high-pressure automatic exhaust. The main valve float assembly 4, seal frame 6, limit plate 7, seal ring 8, throttle ring 11, buffer frame 12, spring 13, exhaust cover 14 and other parts are composed of the main valve float assembly; the micro exhaust valve group is mainly composed of Valve body, micro-exhaust valve group bonnet 20, top plug 22, sealing seat 21, lever assembly 22 (lever, lever frame, hinge, pin), micro-exhaust valve group made of hollowed out polymer material Float 25, float fork and other parts are formed.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com