Electric efficient oral cavity tooth cleaner

A technology for tooth cleaners and oral cavity, applied in the field of oral cleaners, can solve the problems of easy water seepage at the connection between the punch and the handle, inconvenient and quick disassembly and assembly of the punch, breeding of bacteria, etc. Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

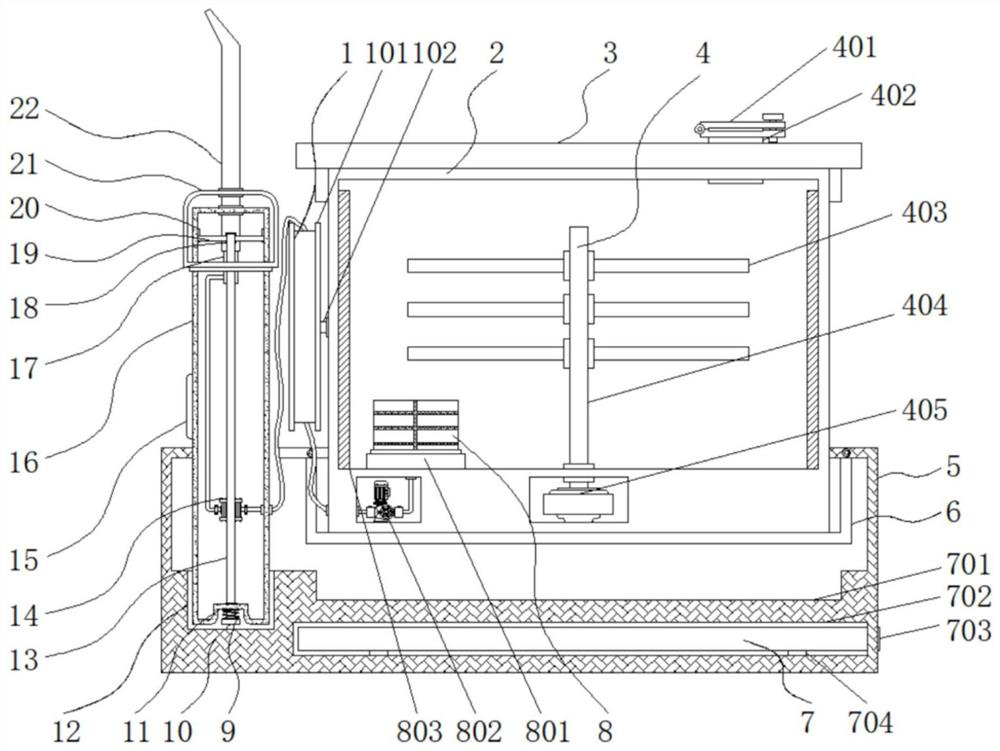

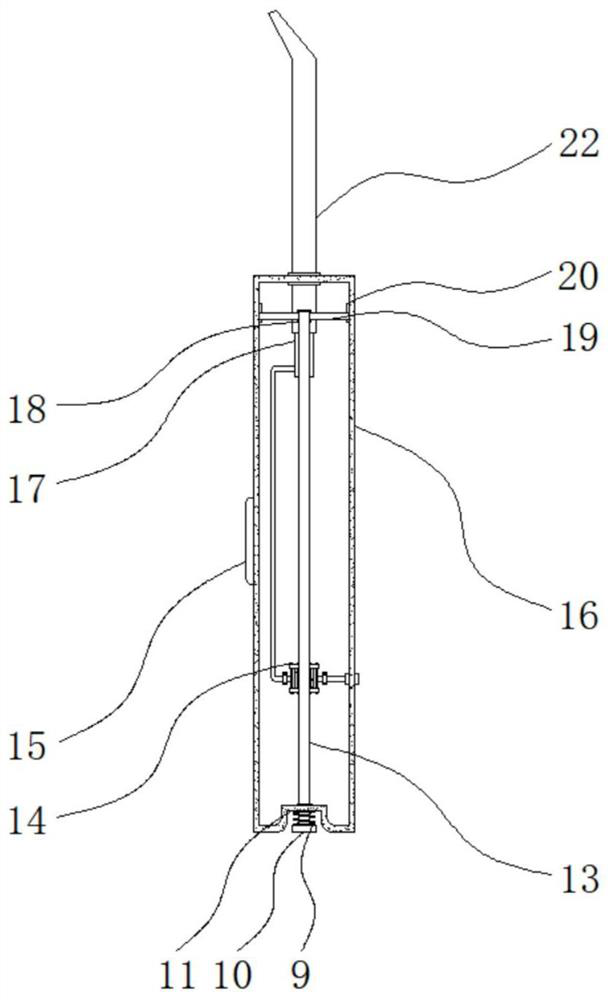

[0035] Example 1: See Figure 1-6 , an electric high-efficiency oral tooth cleaner, comprising a base 5 and a first placement slot 12, a portable storage structure 7 is provided at the bottom end inside the base 5, a first placement slot 12 is provided at one side inside the base 5, and a first placement slot 12 is provided inside the base 5 The top of the tank is provided with a tank 6, and the inside of the tank 6 is embedded with a water storage tank 2, and the top of the water storage tank 2 is fixedly connected with a tank cover 3, and one side of the water storage tank 2 is provided with a winding structure 1, and the inside of the water storage tank 2 is provided with There is a uniform liquid mechanism 4, and both sides of the inner wall of the water storage tank 2 are provided with a sterilization heating mechanism 8, and a handle 16 is embedded in the inside of the first storage tank 12, and a booster pump 14 is arranged inside the handle 16, and the booster pump 14 ...

Embodiment 2

[0039] Embodiment 2: winding structure 1 is made up of winding reel 101, movable shaft 102, first spring 103, first pressure block 104, stop bar 105, coil spring 106 and groove 107, and movable shaft 102 is movably connected in storage On one side of the water tank 2, the outside of the movable shaft 102 is movably sleeved with a winding reel 101, and the inside of the winding reel 101 is provided with a coil spring 106, and the outside of the coil spring 106 is provided with a groove 107. One end is provided with a first briquetting block 104, and a first spring 103 is fixedly connected between the bottom end of the first briquetting block 104 and the reel 101, and a stop rod 105 is arranged at the middle position of the bottom end of the first briquetting block 104, which stops The moving rod 105 vertically penetrates the inside of the winding reel 101 and is embedded in the groove 107, the inside of the coil spring 106 is wound with a hose and one end of the hose is fixedly ...

Embodiment 3

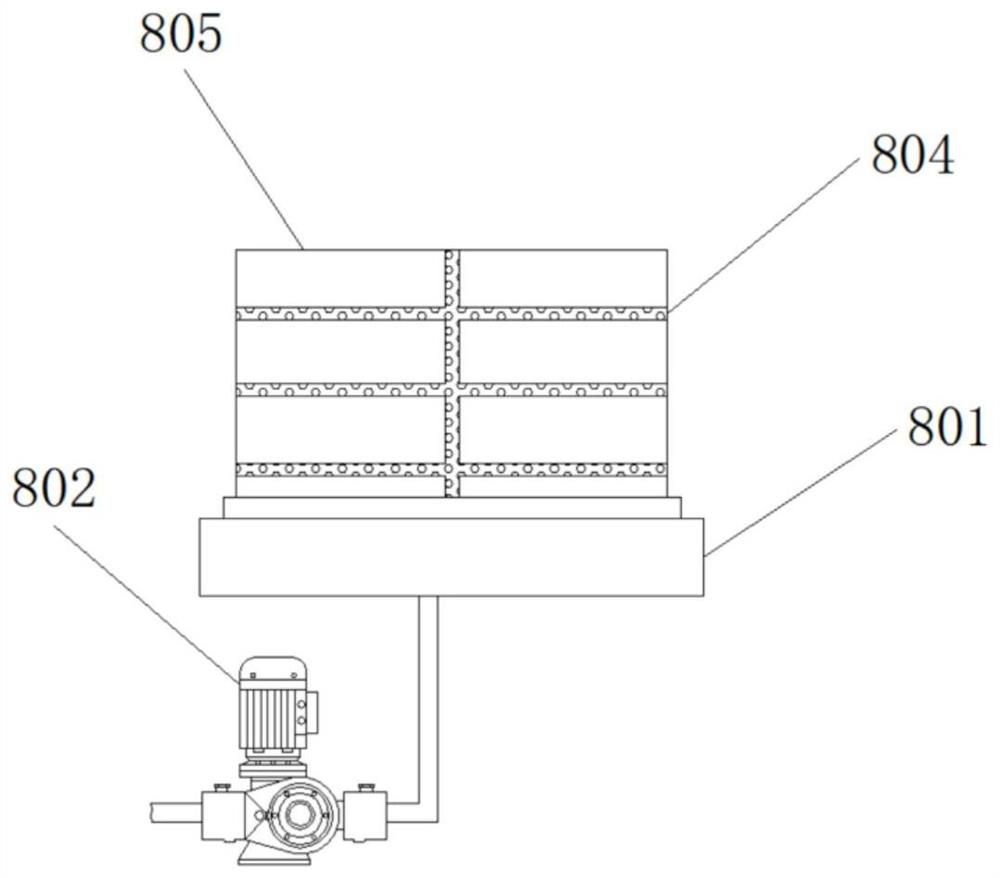

[0042] Embodiment 3: the uniform liquid mechanism 4 is made up of sealing plug 401, liquid inlet 402, stirring rod 403, rotating shaft 404 and driving motor 405, and liquid inlet 402 is arranged on the other side of box cover 3 tops, and the other side of liquid inlet 402 The bottom end communicates with the inside of the water storage tank 2, the top of the liquid inlet 402 is provided with a sealing plug 401, and the drive motor 405 is arranged inside the bottom end of the water storage tank 2. The model of the drive motor 405 can be 25GA370, and the output end of the drive motor 405 A rotating shaft 404 is fixedly connected through a coupling, and three sets of stirring rods 403 are respectively fixedly connected to both sides of the rotating shaft 404;

[0043] The rotating shaft 404 is arranged at the middle position of the bottom end of the water storage tank 2, and the stirring rods 403 are equally spaced between them;

[0044] Specifically, such as figure 1 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com