Cold working method of gh4169 superalloy wire for spring wire

A GH4169, superalloy wire technology, applied in metal processing equipment, metal extrusion cleaning equipment, manufacturing tools, etc., can solve the problems of complex process, increase processing cost, high mold consumption, shorten the process flow, reduce the deformation path Second, the effect of accurate appearance and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

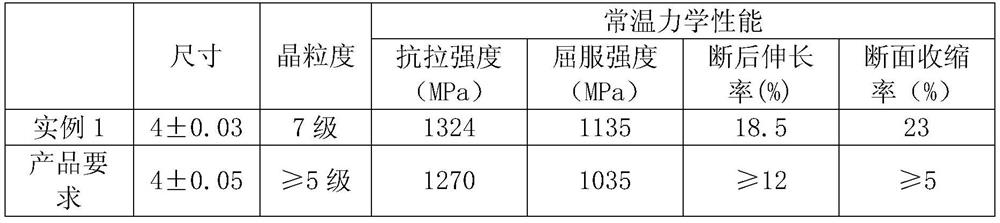

Embodiment 1

[0015] The GH4169 hot-rolled bar in the solid solution state with a diameter of φ8.3mm was subjected to three passes of swaging to obtain a GH4169 alloy wire for spring wire with a diameter of φ4mm. Proceed as follows:

[0016] a. The φ8.3mm hot-rolled bar is placed in a heat treatment furnace for solution treatment, and the solution-treated bar is air-cooled to room temperature; the solution-treatment temperature is 1000°C, and the solution-treatment holding time is 60 minutes;

[0017] b. The φ8.3mm rod blank after the solution treatment described in step a is soaked in a pickling solution for 15 minutes to remove the oxide layer on the surface, rinsed with water and dried to keep the surface of the blank smooth and clean, wherein the pickling solution is made of HNO 3 , HCl and H 2 O is made by mixing in a volume ratio of 1:3:4;

[0018] c, swaging the pickled wire blank described in step b, the swaging feed speed is 8mm / s, and the deformation amount is 44% to obtain a wi...

Embodiment 2

[0029] The GH4169 hot-rolled bar in solid solution state with a diameter of φ8.3mm was subjected to 4 passes of swaging to obtain a GH4169 alloy wire for spring wire with a diameter of φ3mm. Proceed as follows:

[0030] a. The φ8.3mm hot-rolled bar is placed in a heat treatment furnace for solution treatment, and the solution-treated bar is air-cooled to room temperature; the solution-treatment temperature is 1000°C, and the solution-treatment holding time is 60 minutes;

[0031] b. The φ8.3mm rod blank after the solution treatment described in step a is soaked in a pickling solution for 15 minutes to remove the oxide layer on the surface, rinsed with water and dried to keep the surface of the blank smooth and clean, wherein the pickling solution is made of HNO 3 , HCl and H 2 O is made by mixing in a volume ratio of 1:3:4;

[0032]c, swaging the pickled wire blank described in step b, the swaging feed speed is 6mm / s, and the deformation amount is 45%, to obtain a wire blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com