Parallel type full-automatic slicing machine and slicing method

A fully automatic, slicer technology, applied in metal processing and other directions, can solve the problems of not being able to exert the medicinal properties as much as possible, uneven thickness of medicinal material slices, unfavorable sales of medicinal material slices, etc., to achieve fullness, uniformity, and cutting out Yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0033] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

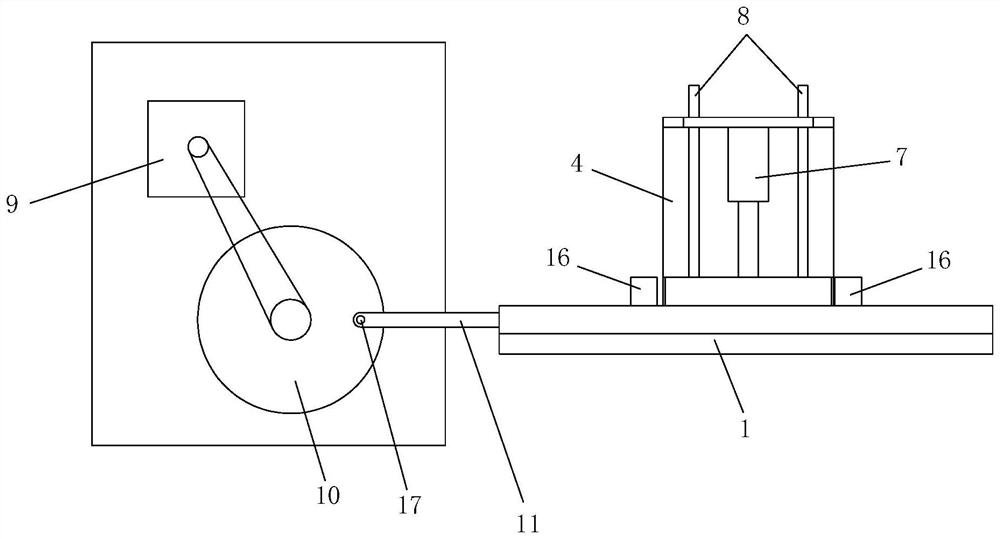

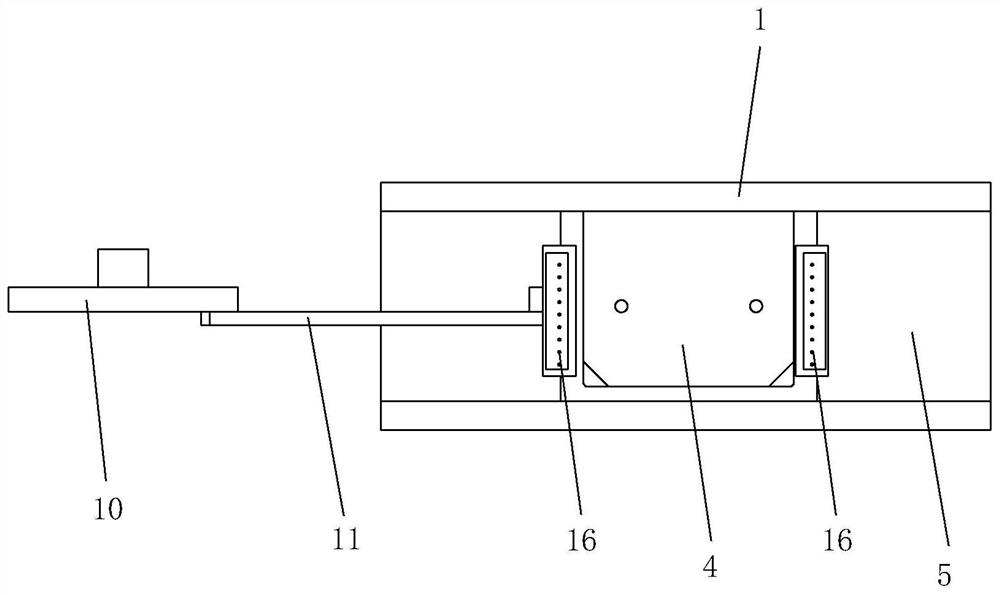

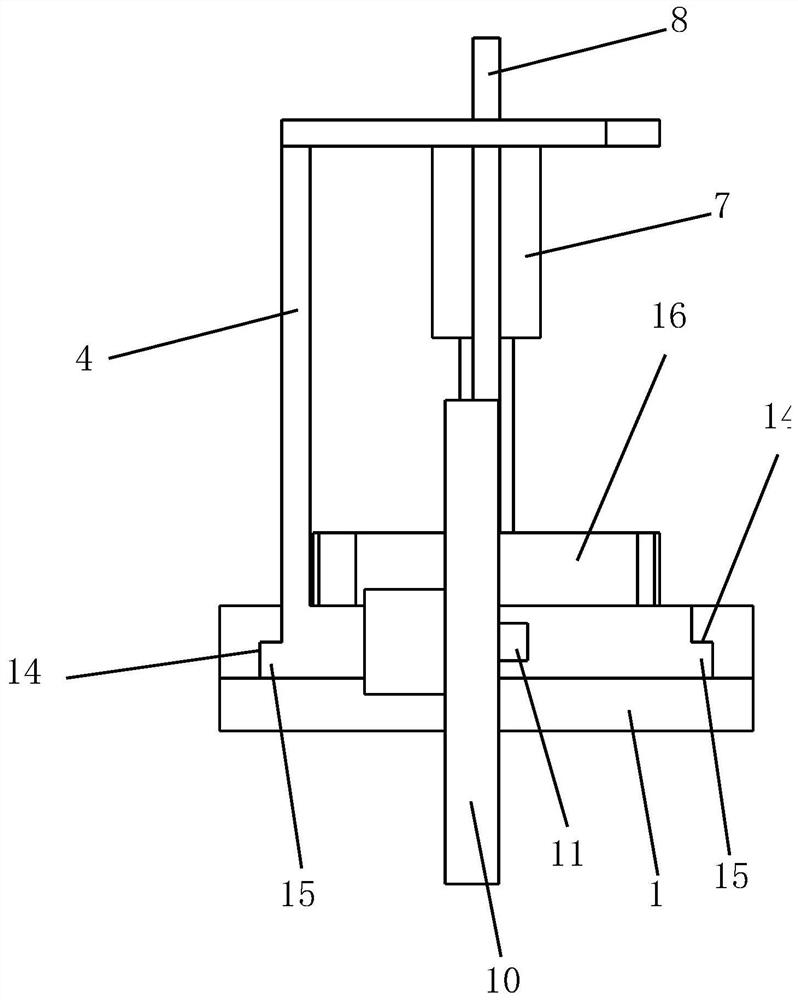

[0034] Such as figure 1 , figure 2 and Figure 4 As shown, this embodiment provides a parallel automatic slicer, including a base 1, a sliding frame 2, a pressing plate 3 and a support 4; the middle part of the base 1 is provided with a chute 5 extending along the horizontal direction, so that The sliding frame 2 is slidably connected in the sliding groove 5 , and the sliding gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com