Protective rear axle housing for automobile rear drive axle

A technology for rear drive axles and rear axle housings, applied to axles, wheels, vehicle parts, etc., can solve the problems of gear oil splashing, no protection or protection, etc., and achieve the effect of easy processing, convenient installation and operation, and overcoming splashing everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

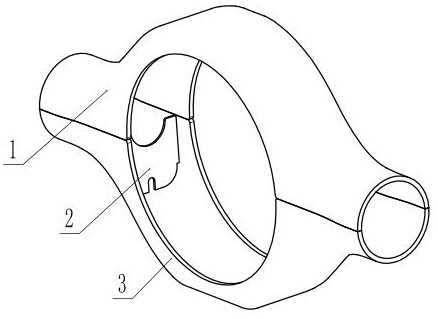

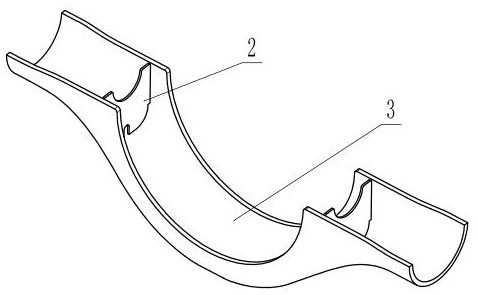

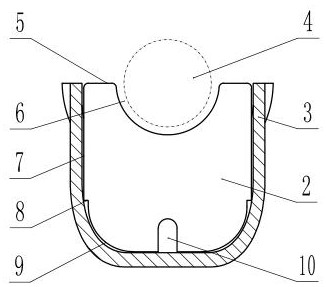

[0015] according to Figure 1~4 The specific structure of the present invention will be described in detail. The protective rear axle housing for the rear drive axle of an automobile comprises an upper rear axle housing body 1 , a lower rear axle housing body 3 and a half shaft oil deflector 2 arranged in the lower rear axle housing body 3 . Wherein the half-shaft oil deflector 2 adopts a flat structure, and each left and right piece is symmetrically and fixedly arranged in the lower body 3 of the rear axle housing. The half-shaft oil baffle 2 has a simple structure, is easy to process, and can be manufactured using leftover materials, thereby significantly reducing manufacturing costs. The half-shaft oil baffle plate 2 of flat structure is installed in the rear axle housing lower body 3 to operate very conveniently, and is easy to be fixed with the rear axle housing lower body 3 by welding.

[0016] The specific structure of the half-shaft oil baffle 2 is as follows: the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com