Quick feeding device for rice straw decoration plate production line

A rice straw and production line technology, which is applied to the field of fast feeding devices for rice straw decoration board production lines, can solve the problems of low production efficiency, long processing time, low strength, etc., and achieve stable discharging, strong adsorption, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

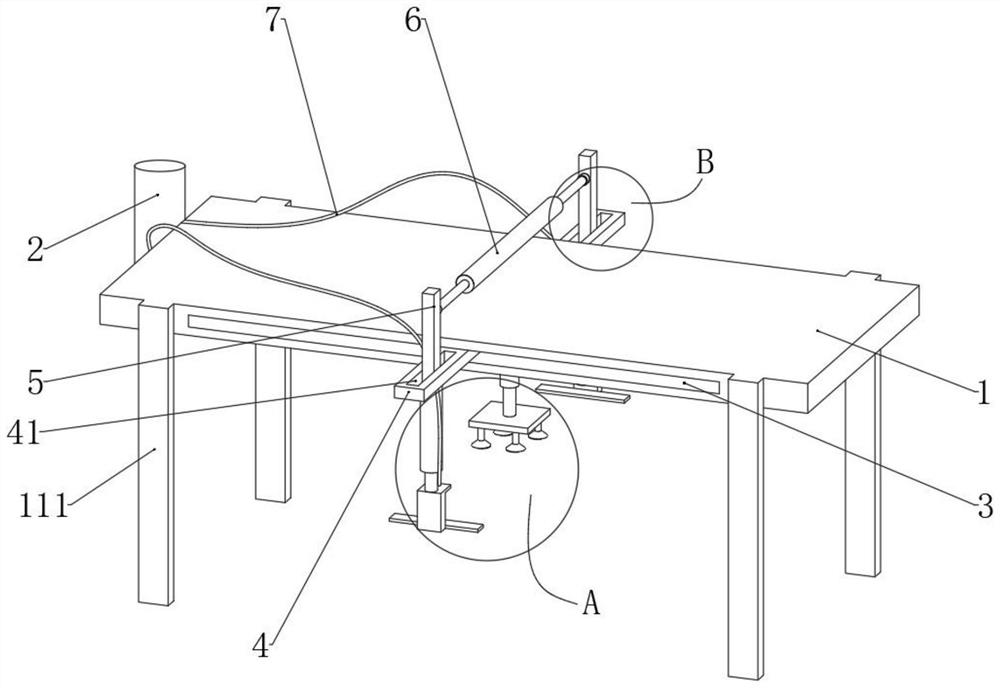

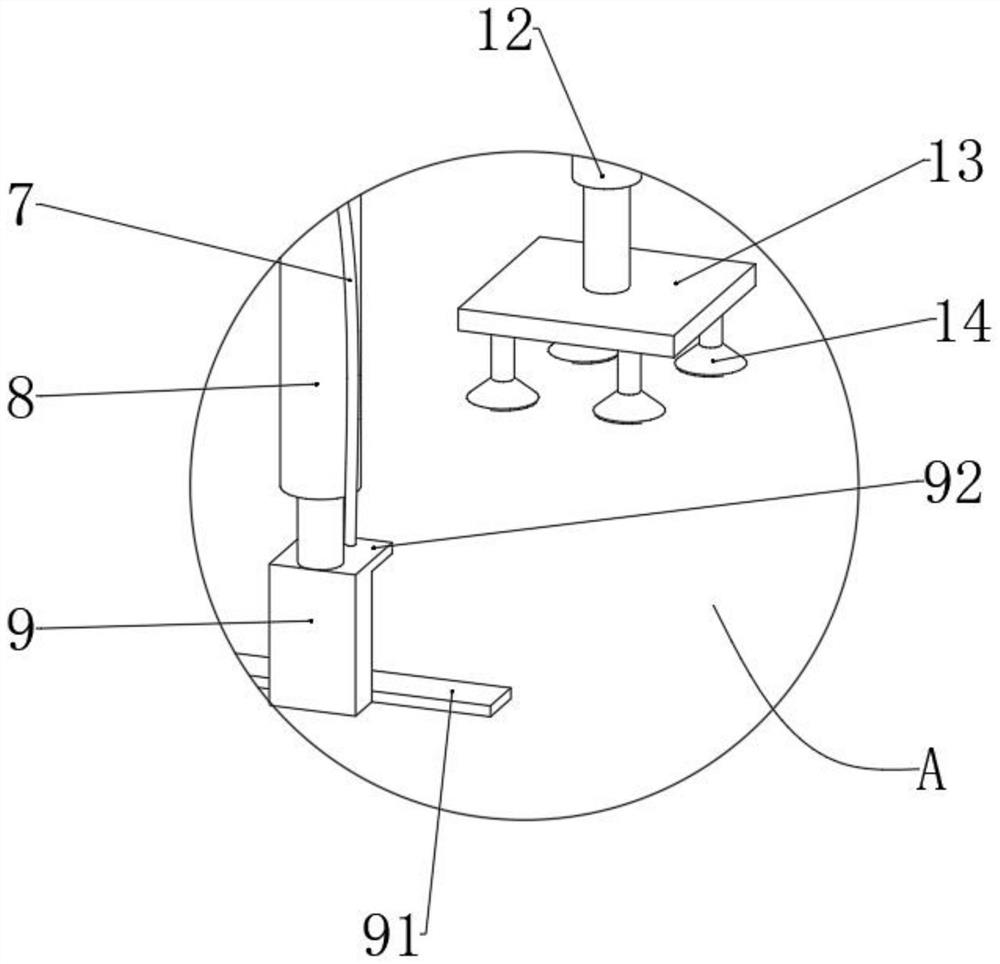

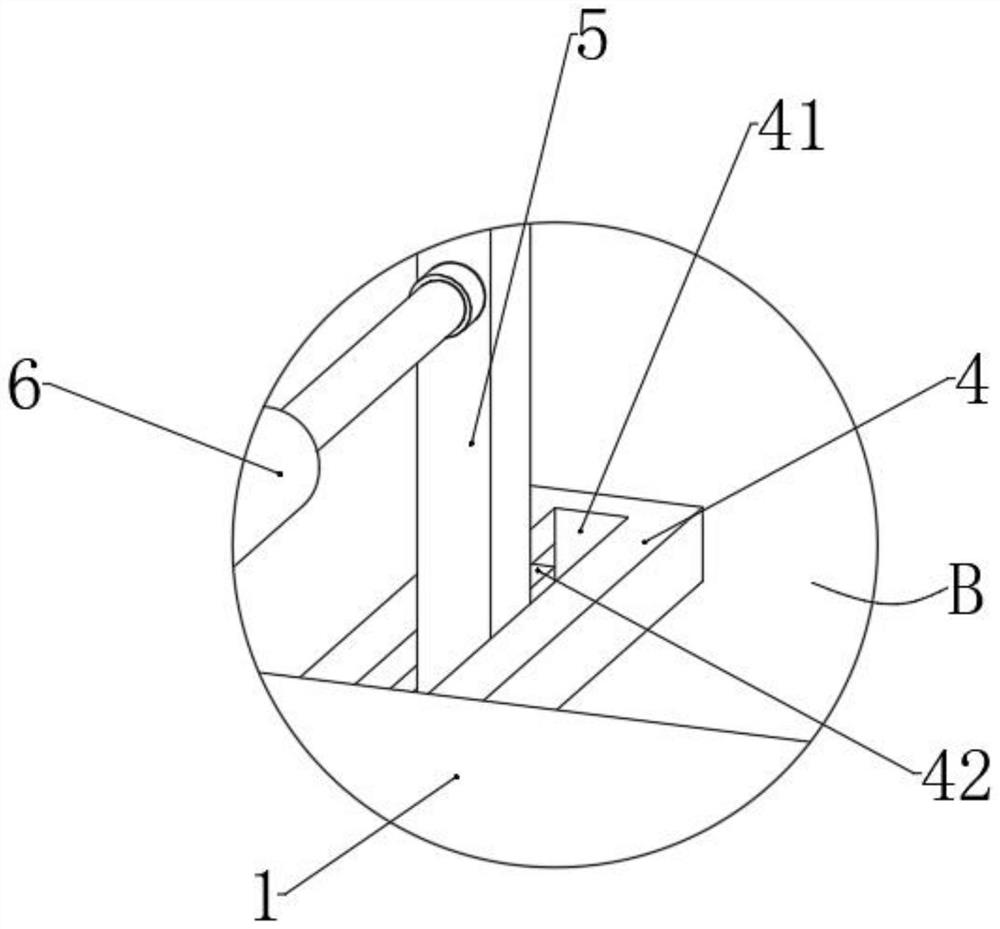

[0029] This embodiment 1 introduces a fast feeding device for a rice straw decorative board production line, including a frame 1, a first station 10 and a second station 11, and the front and rear ends of the frame 1 are welded with support feet 111 , the first station 10 is located under the left side of the frame 1, and the second station 11 is located under the right side of the frame 1, an air pump 2 is installed in the middle of the left end of the frame 1, and the The front end of the frame 1 is provided with a through groove 3, the rear end of the through groove 3 penetrates to the rear end surface of the frame 1, and a crossbeam 4 is slidably installed inside the through groove 3, and the front and rear sides of the crossbeam 4 extend to the Outside the through groove 3, a limiting channel 41 is provided in the middle of the front and rear sides of the crossbeam 4, and a rectangular rod 5 is slidably installed inside the limiting channel 41, and a T-shaped slider is fix...

Embodiment 2

[0031]This embodiment 2 introduces a fast feeding device for a rice straw decoration board production line, including a frame 1, a first station 10 and a second station 11, and the front and rear ends of the frame 1 are welded with support legs 111 , the first station 10 is located under the left side of the frame 1, and the second station 11 is located under the right side of the frame 1, an air pump 2 is installed in the middle of the left end of the frame 1, and the There is a linear chute 112 in the middle of the bottom of the frame 1, the top of the linear chute 112 communicates with the through groove 3, the length of the through groove 3 and the linear chute 112 are the same, and the outer wall of the crossbeam 4 and the The inner walls of the through groove 3 are all polished to smooth, and the frictional resistance is small. An electric slider is installed inside the linear chute 112, and a connecting block is fixed in the middle of the bottom of the crossbeam 4, and t...

Embodiment 3

[0033] This embodiment 3 introduces a fast feeding device for a rice straw decorative board production line, including a frame 1, a first station 10 and a second station 11, and the front and rear ends of the frame 1 are welded with support feet 111 , the first station 10 is located under the left side of the frame 1, and the second station 11 is located under the right side of the frame 1, an air pump 2 is installed in the middle of the left end of the frame 1, and the The front end of the frame 1 is provided with a through groove 3, the rear end of the through groove 3 penetrates to the rear end surface of the frame 1, and a crossbeam 4 is slidably installed inside the through groove 3, and the front and rear sides of the crossbeam 4 extend to the On the outside of the through groove 3, a limiting channel 41 is provided in the middle of the front and rear sides of the crossbeam 4, and a rectangular rod 5 is slidably installed inside the limiting channel 41, and the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com