Coal mine water underground purification treatment equipment

A technology for purification treatment and mines, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of mixing speed, improving purification effect, and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

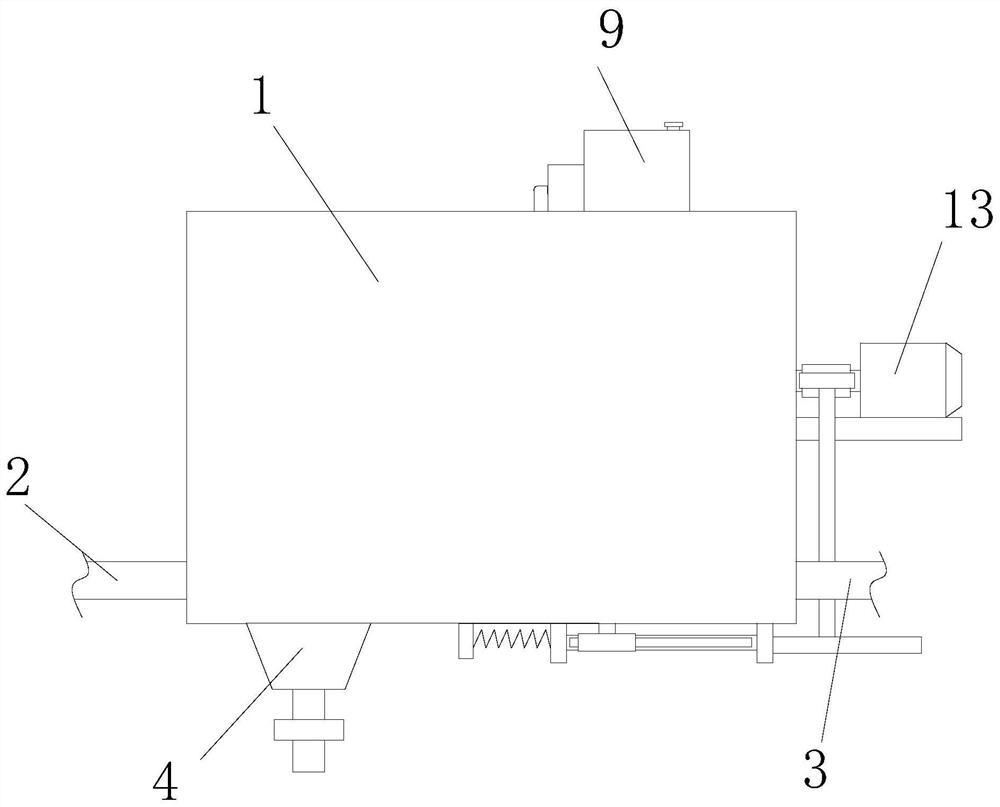

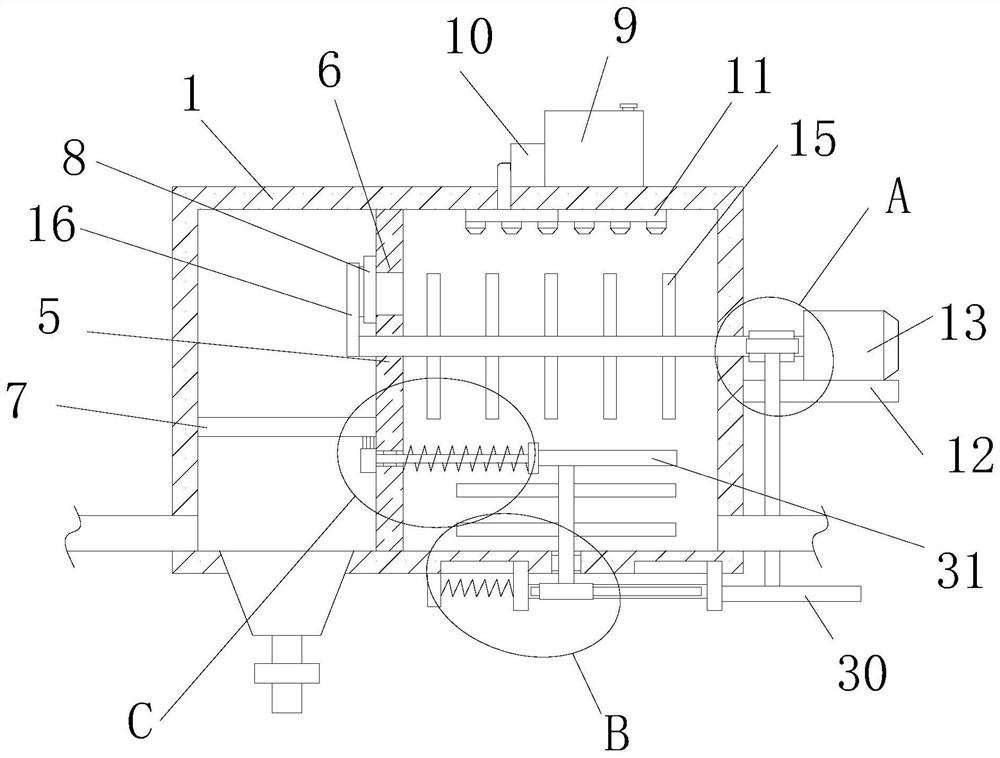

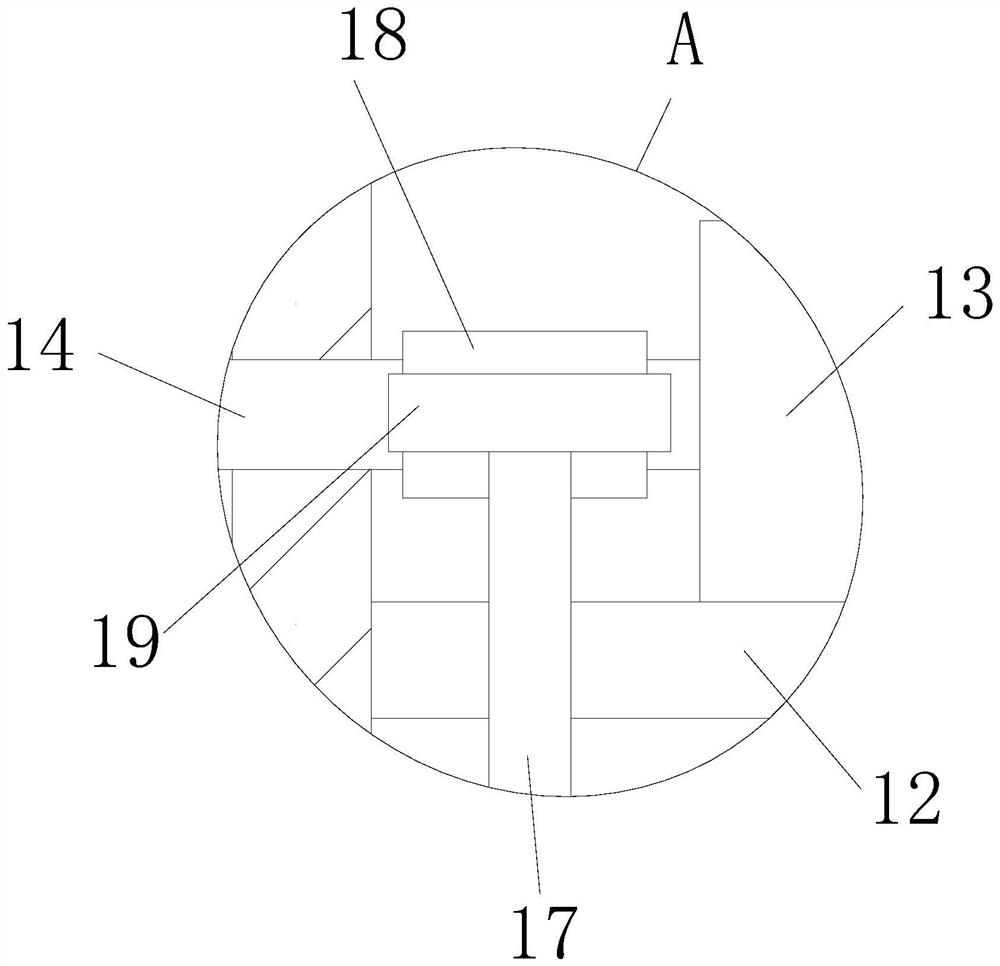

[0110] like Figure 1 to Figure 5 As shown, a coal mine underground water purification treatment equipment, including:

[0111] Treatment box 1, one end is communicated with the water inlet pipe 2, and the other end is communicated with the water outlet pipe 3;

[0112] The partition 5 is arranged in the processing box 1, and divides the processing box 1 into a first cavity and a second cavity, and the upper end is provided with a communication connecting the first cavity and the second cavity hole 6;

[0113] a filter structure, arranged in the first cavity;

[0114] a stirring structure, arranged in the second cavity;

[0115] a cleaning structure, connected with the driving mechanism of the stirring structure, for cleaning the filtering structure;

[0116] The medicated structure is arranged on the upper end of the second cavity.

[0117] In this embodiment, the medicated structure includes:

[0118] The water pump 10 is arranged on the processing tank 1;

[0119] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap