Concrete road shoulder slip form

A technology of concrete and slip form, which is applied in the field of concrete road shoulder slip form, which can solve the problems of long maintenance time, long construction period, handling damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

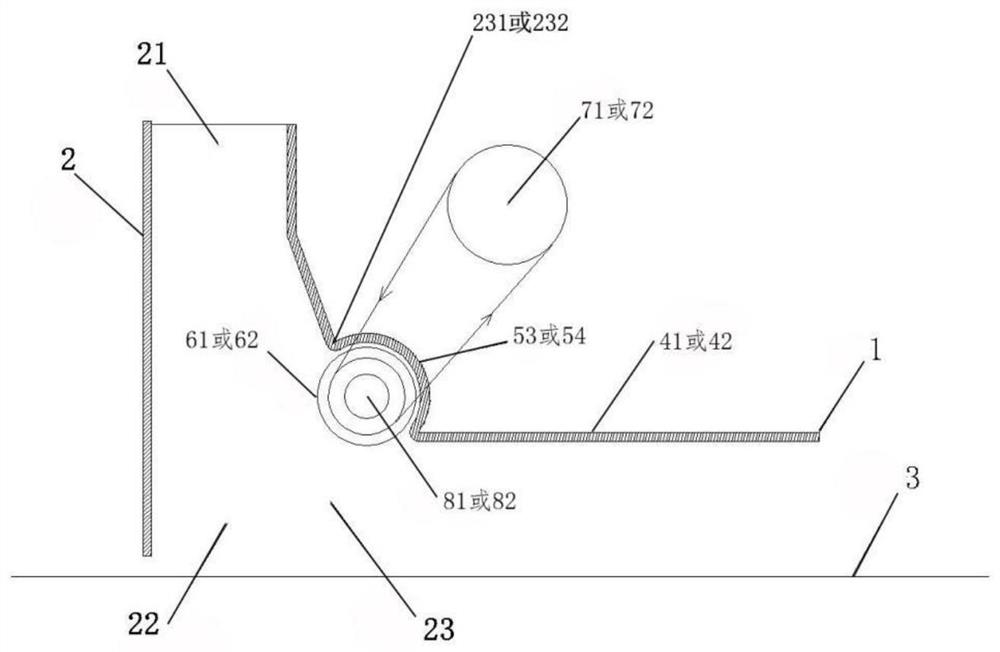

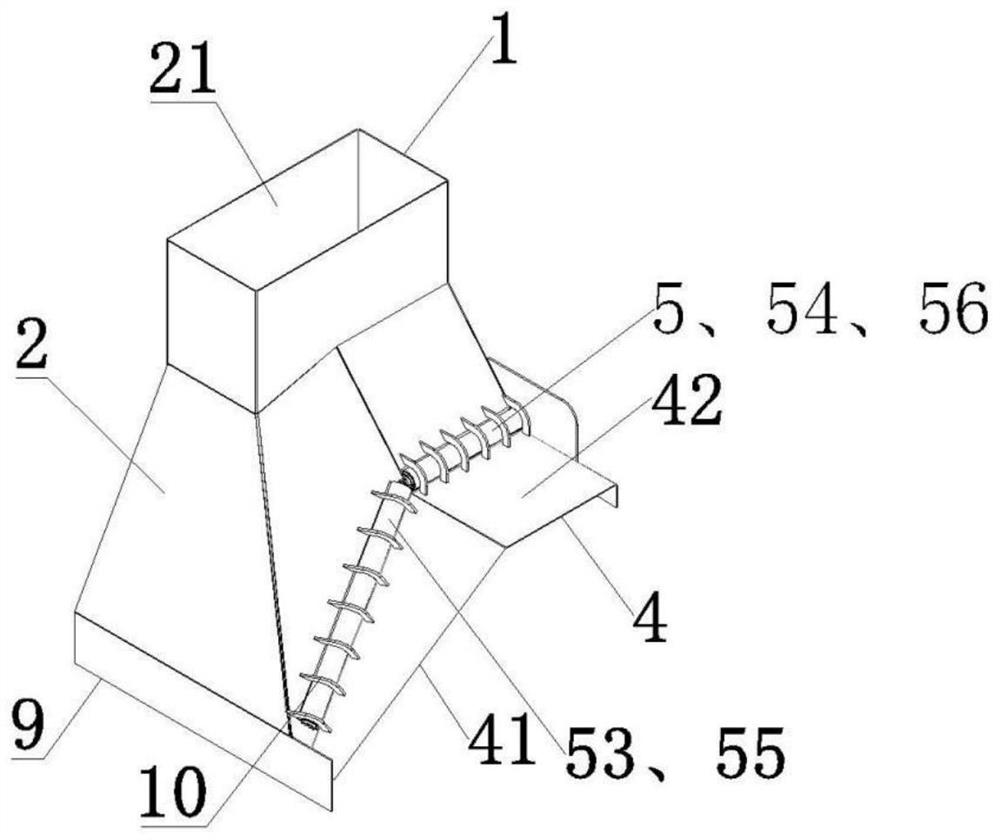

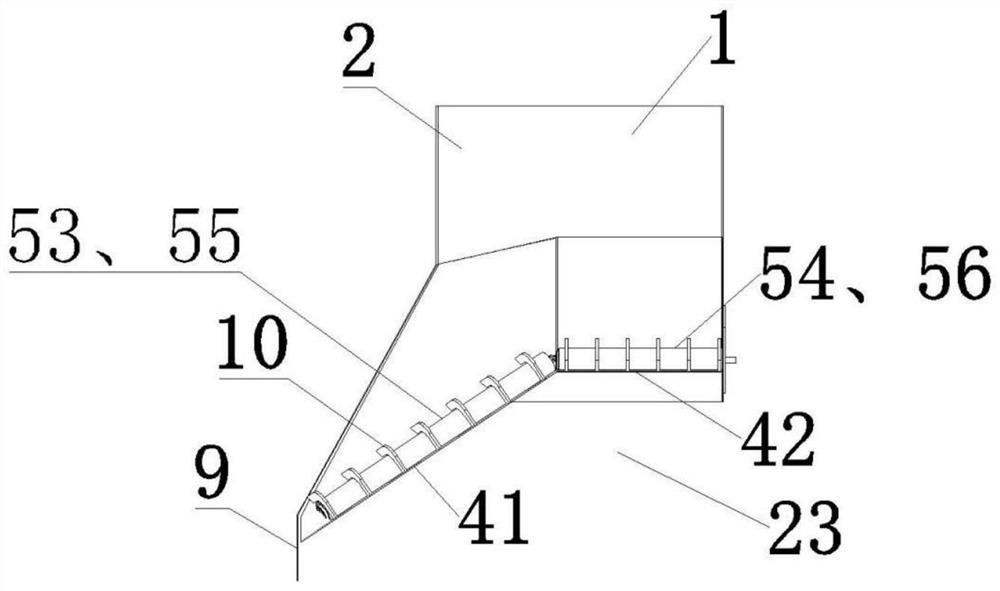

[0035] In one embodiment, as Figure 1-6 Shown, concrete road shoulder slip form, this slip form (1) comprises a hopper (2), and this hopper (2) has a feeding port (21) and a discharge port (22) that opens downward, and described hopper (2) The lower end of the side wall is concave upwards to form a discharge gap (23); and an open downward shaping formwork (4), said shaping formwork (4) is assembled by plane formwork (41,42) into; the sliding form (1) also includes an arc template (5), a roller (6), a motor (7) and a speed reducer (8), wherein,

[0036] The profile of the discharge gap (23) matches the profile of the cross-section of the concrete shoulder;

[0037] The outline of the cross-section of the shaping template (4) matches the outline of the discharge gap (23);

[0038] The arc-shaped template (5) is connected between the front end of the plane t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com