A kind of construction method of pile stabilization platform aggregate assembly

A construction method and platform technology, applied in construction, load hanging components, artificial islands, etc., can solve problems such as increased risk of high-altitude operations, unfavorable construction of pile-stabilized platforms, and high requirements for lifting equipment, so as to shorten the production cycle and reduce the The limitation of site lifting capacity and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing.

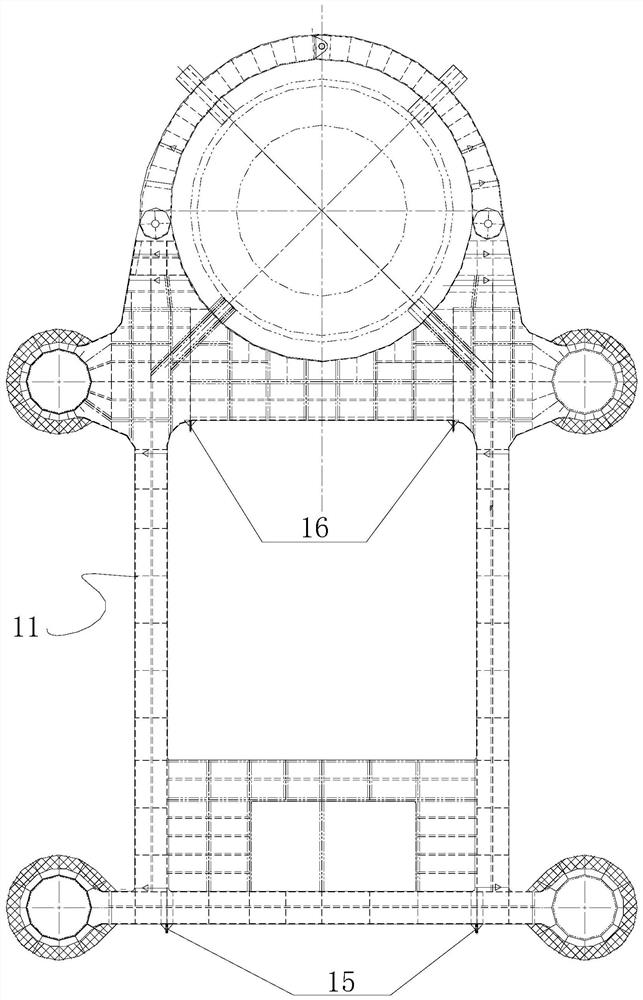

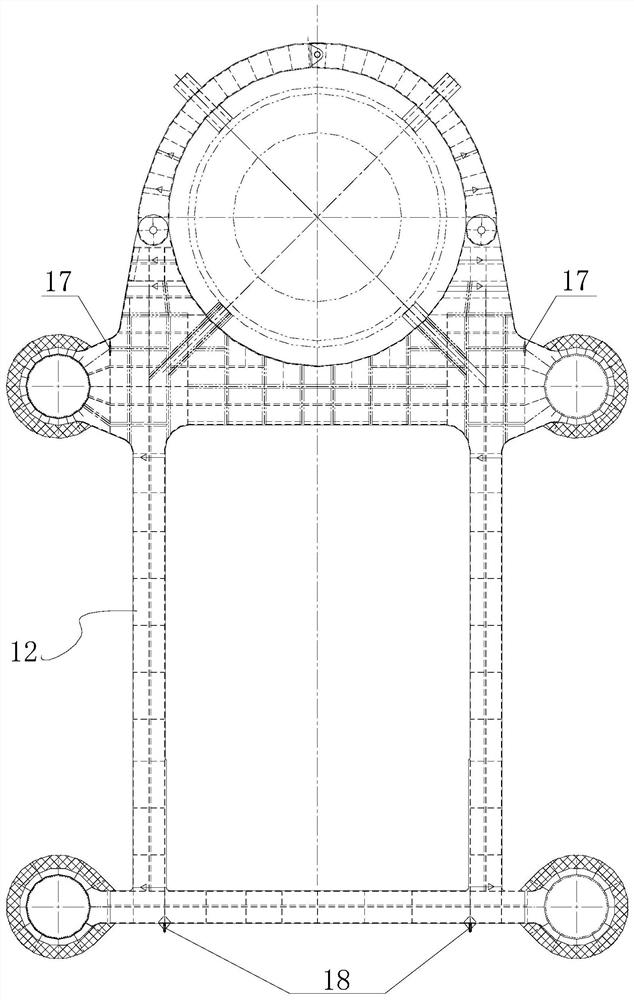

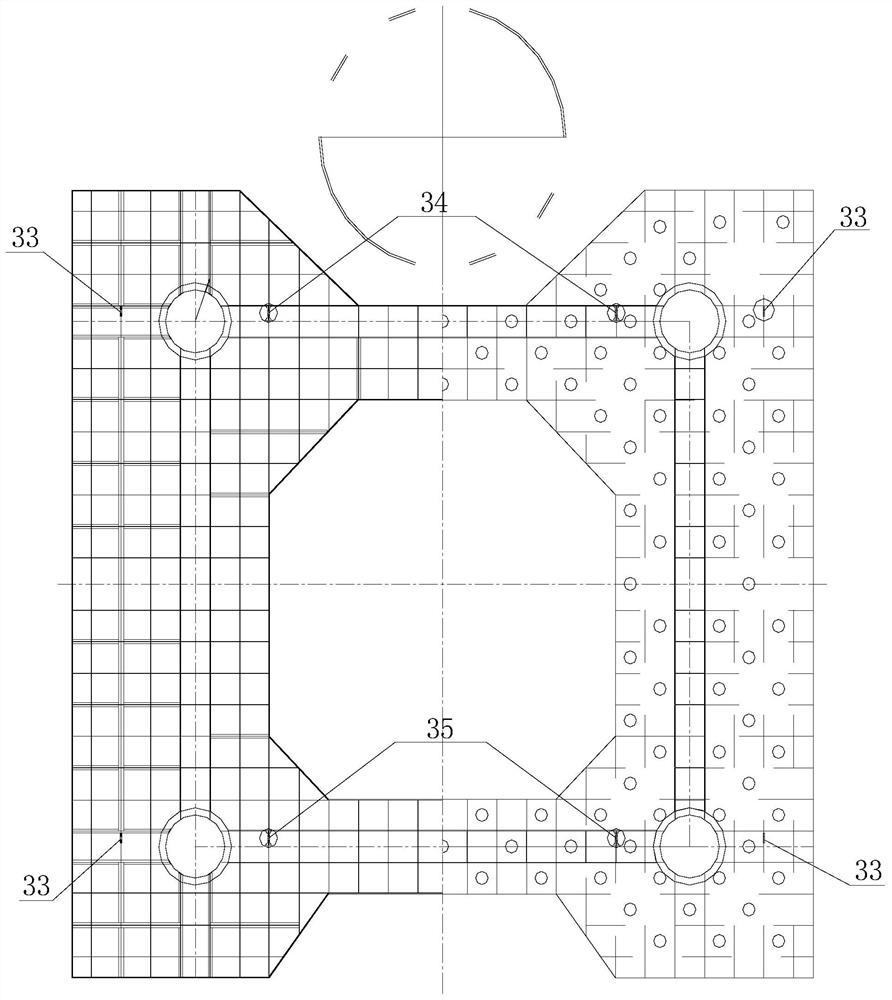

[0054] see Figure 1 to Figure 10 , The construction method of the assembly of the pile-stabilizing platform of the present invention, the pile-stabilizing platform involved includes three major components, namely a pile holding device 1, a jacket 2 and an anti-settling plate 3. The pile holder includes an upper platform 11 of the pile holder, a lower platform 12 of the pile holder, and a support column 13 and a support brace 14 connected between the upper platform 11 of the pile holder and the lower platform 12 of the pile holder; the jacket 2 includes a conduit Frame left piece 21, jacket right piece 22 and connecting pipe 23 connected between the jacket left and right pieces;

[0055] The construction method that the pile-stabilizing platform assembly of the present invention is combined adopts a horizontal assembly and includes the following processes:

[0056] Proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com