Reciprocating mechanical equipment fault detection method based on real-time vibration data

A technology for fault detection and mechanical equipment, which is used in the testing of mechanical equipment, engines, and mechanical components. It can solve problems such as strong randomness, sensitive operating conditions, and inability to locate faults. The effect of small volume and good engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

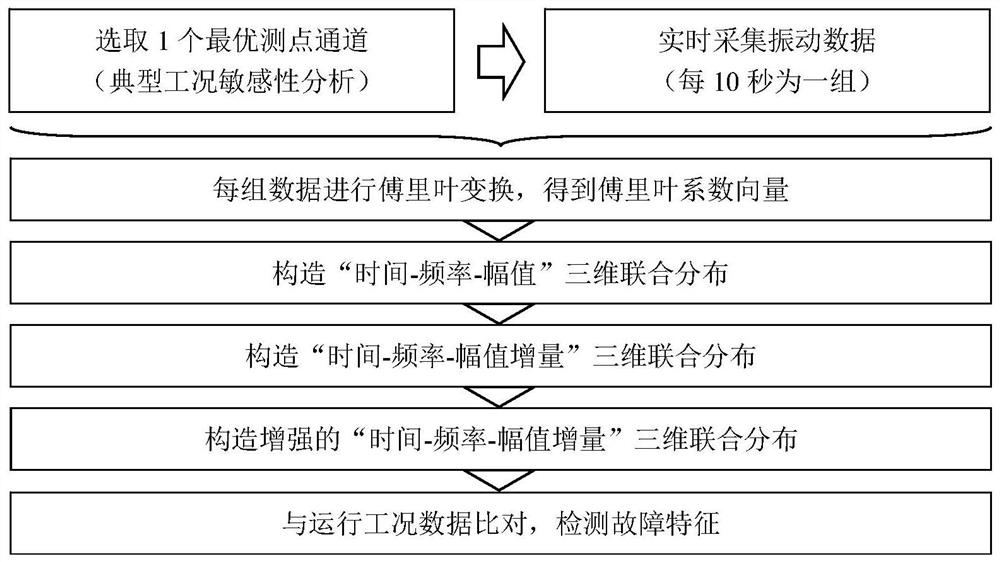

[0024] The invention provides a fault detection method for reciprocating mechanical equipment based on real-time vibration data. The specific implementation steps of the method are as follows:

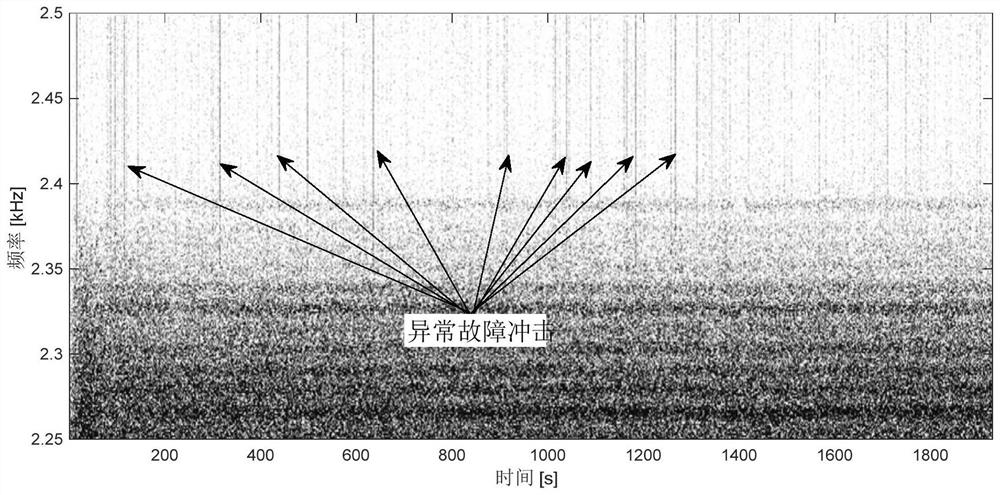

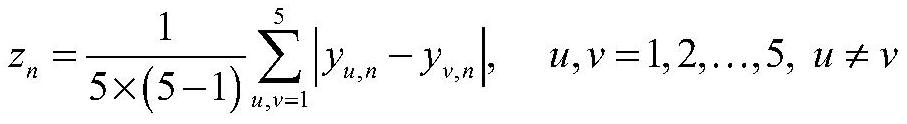

[0025] Step 1: For the target equipment, set 5 load states at rated speed, which are 100% rated load, 120% rated load, 80% rated load, 50% rated load, and 20% rated load. First of all, based on experience, select common vibration measurement points such as the target equipment base, bearing seat, shell position in the reciprocating motion direction, axial position, etc., and run for 10 minutes under the above five load states to collect vibrations under each working condition. Measurement point data. Assuming that there are 10 candidate measuring points, the measured data of the nth vibration measuring point under the mth working condition is written as x mn , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com