Preparation method, batch observation method and observation device of microstructure

A microstructure and electron microscopy technology, which is applied in the direction of measuring devices, preparation of test samples, and material analysis through optical means, can solve the problem of not being easy to distinguish the front or back of the cover glass, and achieve efficient observation and cumbersome optimization. Steps, time-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

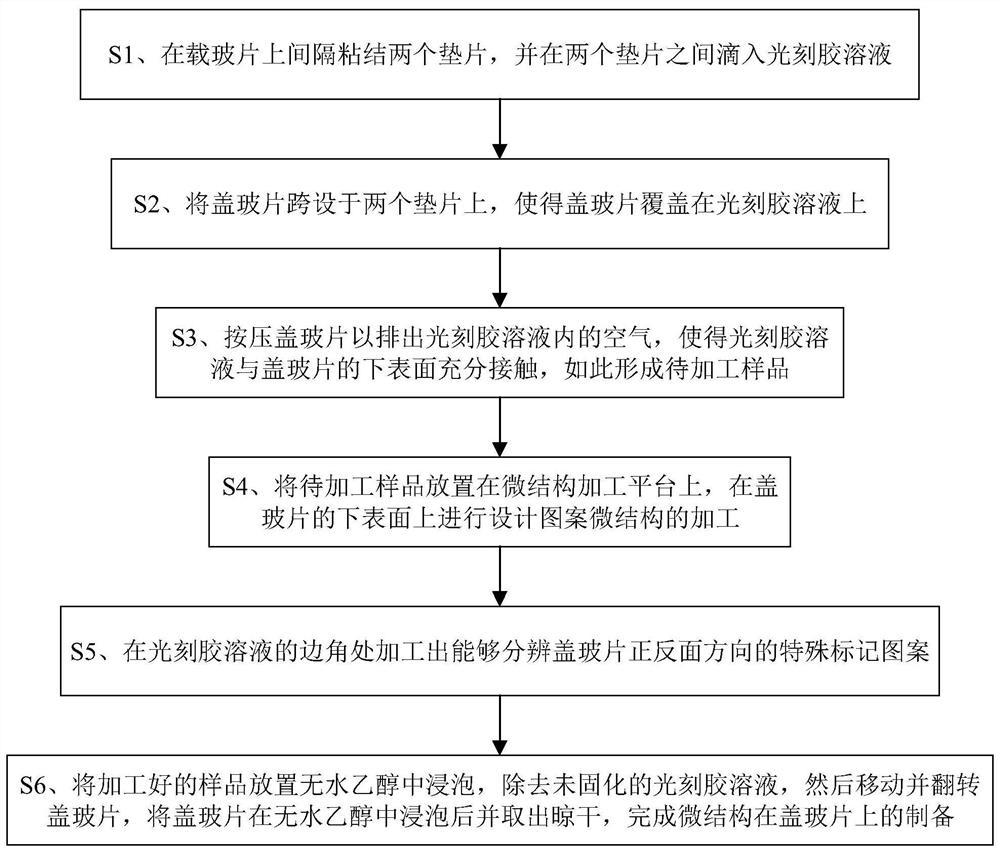

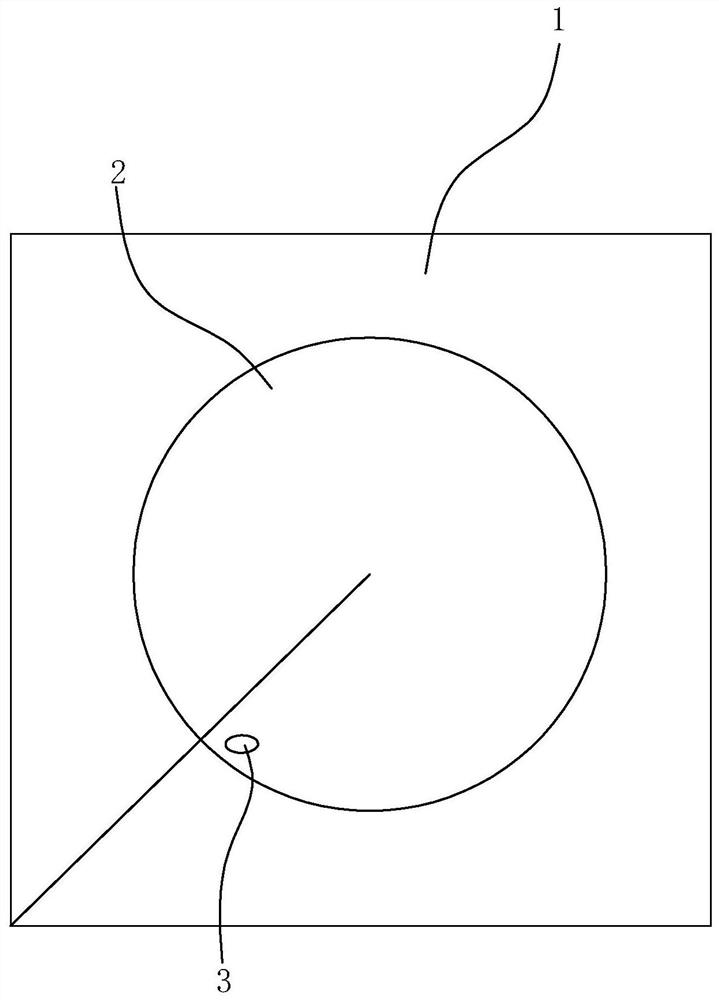

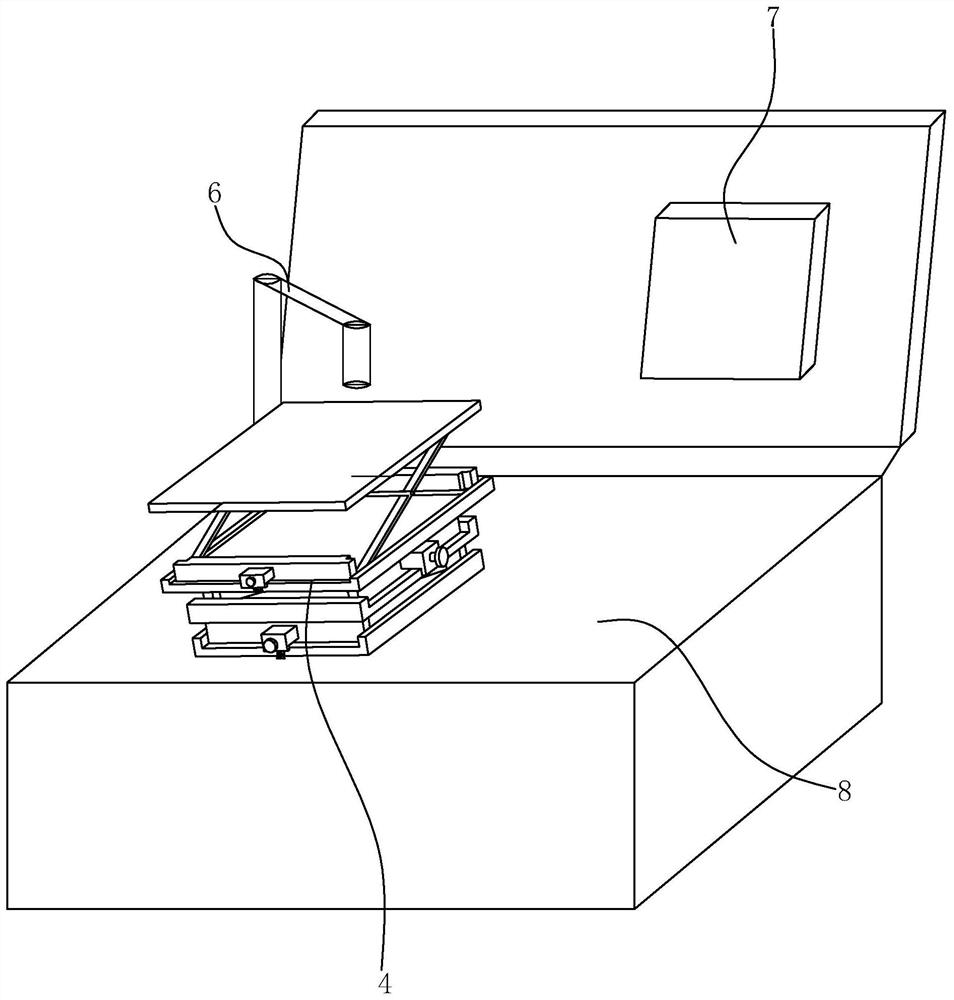

[0043] Such as figure 1 As shown, the preparation method of the microstructure in this embodiment comprises the following steps:

[0044] S1. Bond two pads at intervals above the glass slide. The pads used in this embodiment are two layers of adhesive tape. 3 along the width direction of the slide glass and bonded on the slide glass so that the distance between the two pads is 1-1.5 cm. Since the spacers have a certain thickness, a groove is formed between the two spacers on the glass slide, and then the photoresist solution 2 is dropped into between the two spacers. During operation, use a disposable dropper to draw a small amount of photoresist solution 2 and drop it on the center of the glass slide.

[0045] S2. Place the cover glass 1 across the two pads so that the cover glass 1 covers the photoresist solution 2. The cover glass 1 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com