Method and apparatus for treating discharge gas containing target gas in plasma state

A plasma and exhaust gas technology, applied in the field of target gas conversion rate, can solve the problems of shortening life, increasing maintenance costs, increasing the number of operation interruptions, etc., and achieves the effects of increasing life, reducing maintenance costs, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

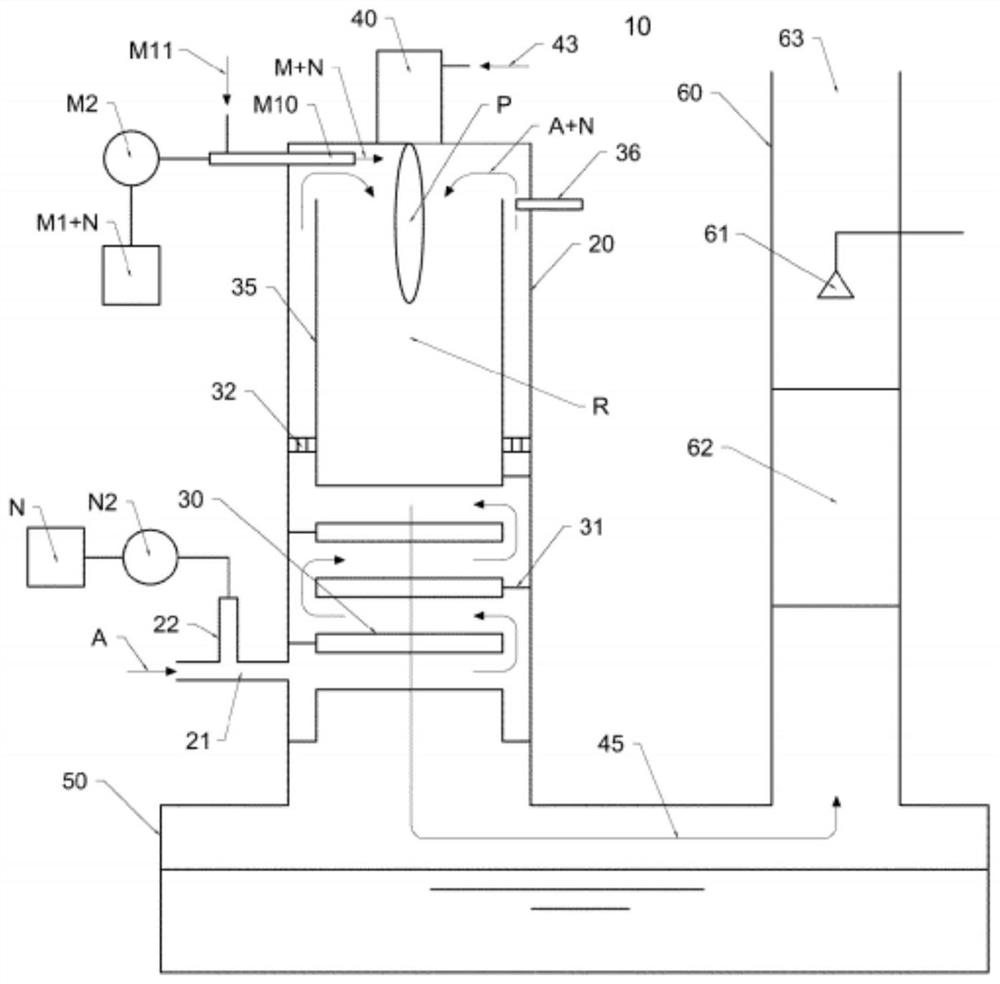

[0077] figure 1 This is a conceptual diagram of an apparatus for processing an exhaust gas containing a target gas in a plasma phase according to an embodiment of the present invention. The exhaust gas treatment device 10 is roughly composed of a main body 20 , a heat exchanger 30 and a conduit 35 , a plasma generation device 40 , a water tank 50 , a wet scrubber 60 , and an atomizer M10 . The exterior of the main body 20 is thermally insulated.

[0078] The exhaust gas A containing the target gas flows in through the exhaust gas introduction port 21 containing the target gas. After the reforming agent N whose supply rate is adjusted by the quantitative supply device N2 is injected through the reforming agent supply port 22 provided in the exhaust gas introduction port 21 containing the target gas, it is mixed with the exhaust gas A containing the target gas, and the mixture is After the in-line heat exchanger 30 of the stage has passed through the conversion zone, the waste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap