Auxiliary spraying device for stage

A spray device and stage technology, which is applied to stage devices, devices used in theaters, circuses, etc., entertainment, etc., can solve the problems of inconvenient height adjustment, environmental protection, and affecting actors' performances, so as to improve the adjustment effect and improve practicability , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

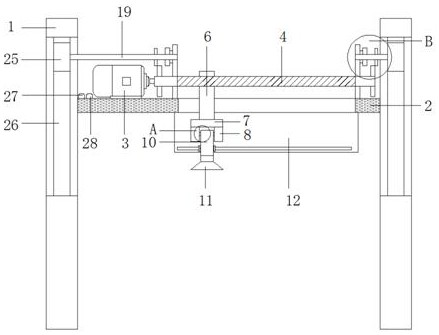

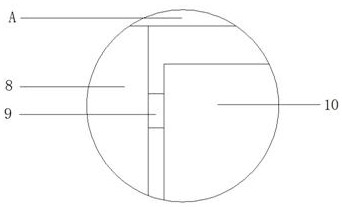

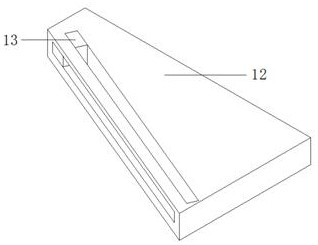

[0026]Example 1, referenceFigure 1-7One stage auxiliary spray device, including two support plates 1 and sliding mounting plate 2 on the outer wall of the two support plates 1 opposite to the outer wall of the mounting plate 2, by the bolt, connected to the low speed motor 3 And the output shaft of the low speed motor 3 is connected to the drive screw 4 through the coupling, and the outer wall of the top ends of the mounting plate 2 is welded to the fixing plate 5, and the drive screw 4 is connected to two fixation plates by bearings. On the side wall, the drive screw 4 includes two transmission rods and both ends that are welded to the thread rods on the outer wall of the two transmission rods, and the two drive rods are connected to the two fixed plates 5 side by bearings. On the outer wall, the drive screw 4 is screwed between the outer walls between the two fixing plates 5, and the top of the mounting plate 2 is located on the outer wall of the transmission screw 4, and the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com