Wafer cleaning device

A technology for cleaning devices and wafers, applied in cleaning methods and tools, cleaning methods using liquids, static electricity, etc., can solve problems such as wafer yield decline, poor arcing, etc., to eliminate static charges, ensure quality, and increase revenue rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

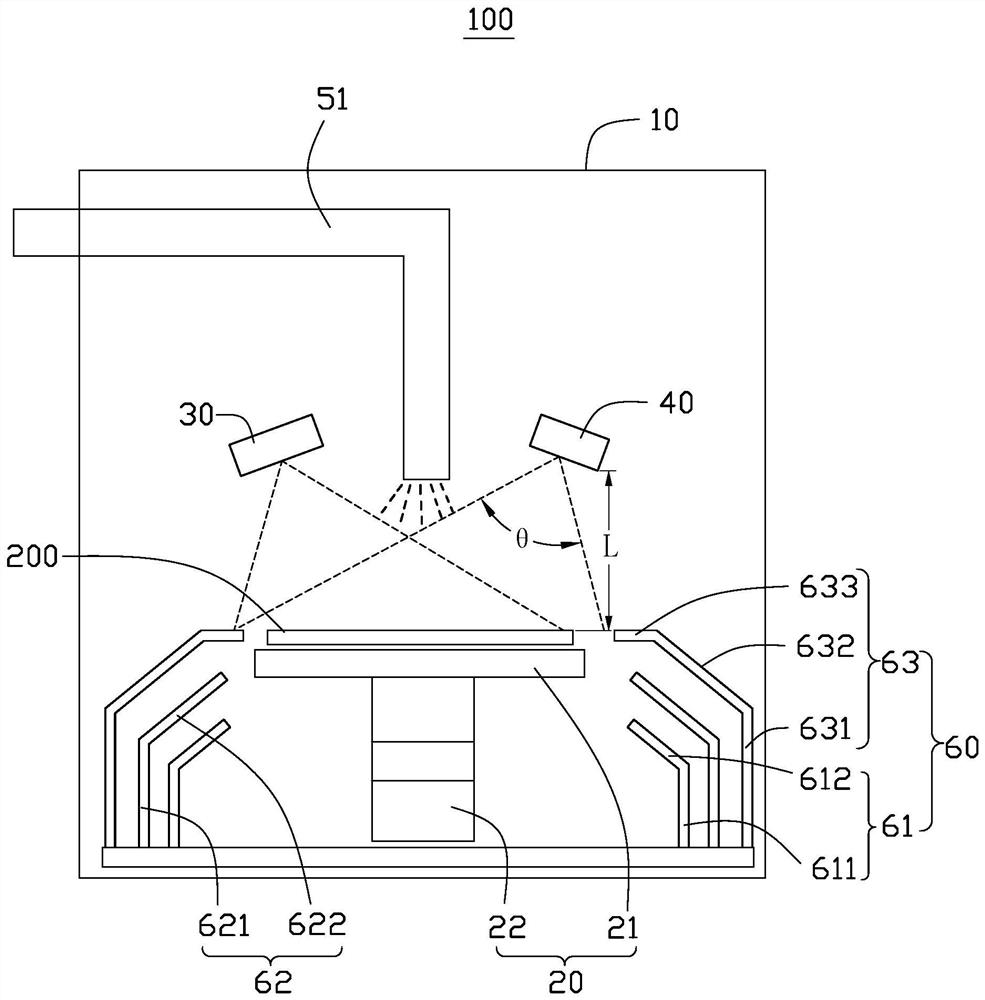

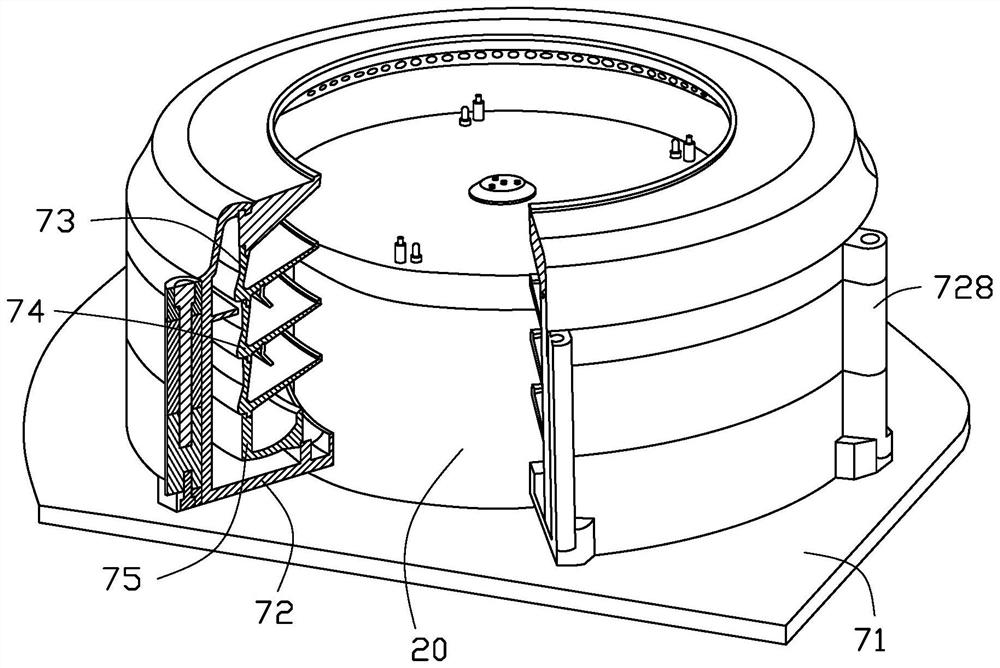

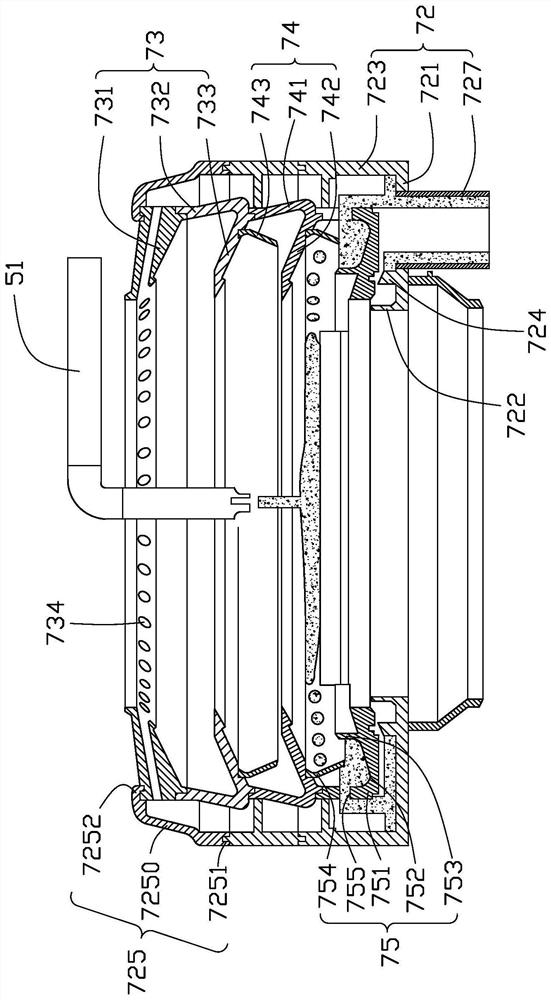

[0055] see figure 1 , the wafer cleaning device 100 provided in the first embodiment of the present invention can eliminate the static electricity generated by the wafer 200 during the cleaning process. The wafer cleaning device 100 includes a spin chamber 10, a spin assembly 20, an electrostatic sensor 30, a soft X-ray ionizer 40, a cleaning fluid supply assembly (not shown) and a cleaning fluid recovery assembly 60, wherein the rotation assembly 20, the electrostatic The sensor 30 , the soft X-ray ionizer 40 and the cleaning fluid recovery assembly 60 are all disposed in the spin chamber 10 .

[0056] The rotating assembly 20 includes a rotating table 21 and a driving assembly 22 , the rotating table 21 is disposed on the driving assembly 22 and rotates under the driving action of the driving assembly 22 . The turntable 21 is used to carry the wafer 200 . Further, the turntable 21 is provided with a suction cup (not shown) for holding the wafer 200 so that the wafer 200 ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com