High-dust-proof high-heat-preservation pesticide-resistant PO film functional master batch, five-layer co-extrusion PO film and preparation method thereof

A functional masterbatch, high thermal insulation technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, agriculture, etc., can solve the problem of no clear additive addition method, difficult to guarantee the quality and performance of PO film products, and difficult to ensure uniform dispersion. and stable extrusion volume to achieve the effect of reducing the loss of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

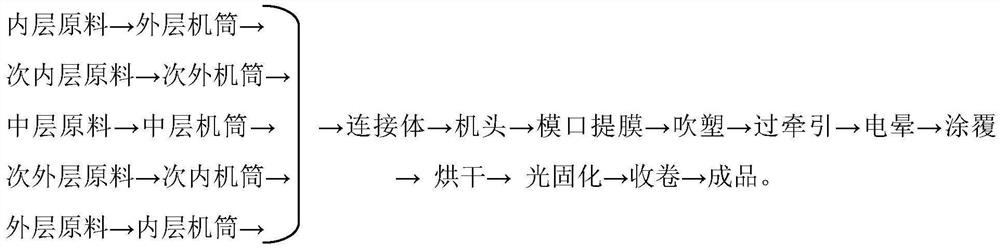

[0059] The outer dust-proof and long-life masterbatch of the five-layer co-extruded PO film, the sub-outer infrared barrier masterbatch, the middle thermal insulation masterbatch, the sub-inner infrared barrier masterbatch, and the inner polar masterbatch are composed of the following mass percentages: Made from ingredients:

[0060] Outer dust-proof and long-life masterbatch: low-density polyethylene powder 17%, linear low-density polyethylene powder 60%, hindered amine light stabilizer XT100 6%, hindered phenolic antioxidant 1.5%, phosphite antioxidant 1.5%, UV absorber 3%, antistatic agent 5%, dispersant 4%, slip agent 2%, PPA processing aid 2‰;

[0061] Sub-outer infrared blocking masterbatch: 18% low-density polyethylene powder, 52% linear low-density polyethylene powder, 4% hindered amine light stabilizer XT100, 1% hindered phenolic antioxidant, phosphite antioxidant 1%, transparent heat preservation agent 20%, dispersant 4%, PPA processing aid 2‰;

[0062] Middle laye...

Embodiment 2

[0095] The outer dust-proof and long-life masterbatch of the five-layer co-extruded PO film, the sub-outer infrared barrier masterbatch, the middle thermal insulation masterbatch, the sub-inner infrared barrier masterbatch, and the inner polar masterbatch are composed of the following mass percentages: Made from ingredients:

[0096] Outer dust-proof and longevity masterbatch: 25% low-density polyethylene powder, 50% linear low-density polyethylene powder, 8% hindered amine light stabilizer XT100, 1.5% hindered phenolic antioxidant, phosphite antioxidant 1.5%, UV absorber 3%, antistatic agent 5%, dispersant 4%, slip agent 2%, PPA processing aid 2‰;

[0097] Sub-outer infrared blocking masterbatch: 15% low-density polyethylene powder, 50% linear low-density polyethylene powder, 4% hindered amine light stabilizer XT100, 1% hindered phenolic antioxidant, phosphite antioxidant 1%, transparent heat preservation agent 25%, dispersant 4%, PPA processing aid 2‰;

[0098] Middle laye...

Embodiment 3

[0109] The outer dust-proof and long-life masterbatch of the five-layer co-extruded PO film, the sub-outer infrared barrier masterbatch, the middle thermal insulation masterbatch, the sub-inner infrared barrier masterbatch, and the inner polar masterbatch are composed of the following mass percentages: Made from ingredients:

[0110] Outer dust-proof and longevity masterbatch: 20% low-density polyethylene powder, 52% linear low-density polyethylene powder, 8% hindered amine light stabilizer XT100, 2% hindered phenolic antioxidant, phosphite antioxidant 2%, UV absorber 4%, antistatic agent 5%, dispersant 4%, slip agent 3%, PPA processing aid 2‰;

[0111] Sub-outer infrared blocking masterbatch: 22% low-density polyethylene powder, 53% linear low-density polyethylene powder, 4% hindered amine light stabilizer XT100, 1% hindered phenolic antioxidant, phosphite antioxidant 1%, transparent heat preservation agent 15%, dispersant 4%, PPA processing aid 2‰;

[0112] Middle layer in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com