A disposable absorbent product

An absorbent, disposable technology, applied in applications, flat products, household appliances, etc., can solve problems such as easy generation of static electricity, environmental pollution, and health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A disposable absorbent article comprising, from top to bottom, a liquid-permeable topsheet, an absorbent core, a liquid-impervious backsheet, and a syndiotactic release film.

[0023] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0024] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0025] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

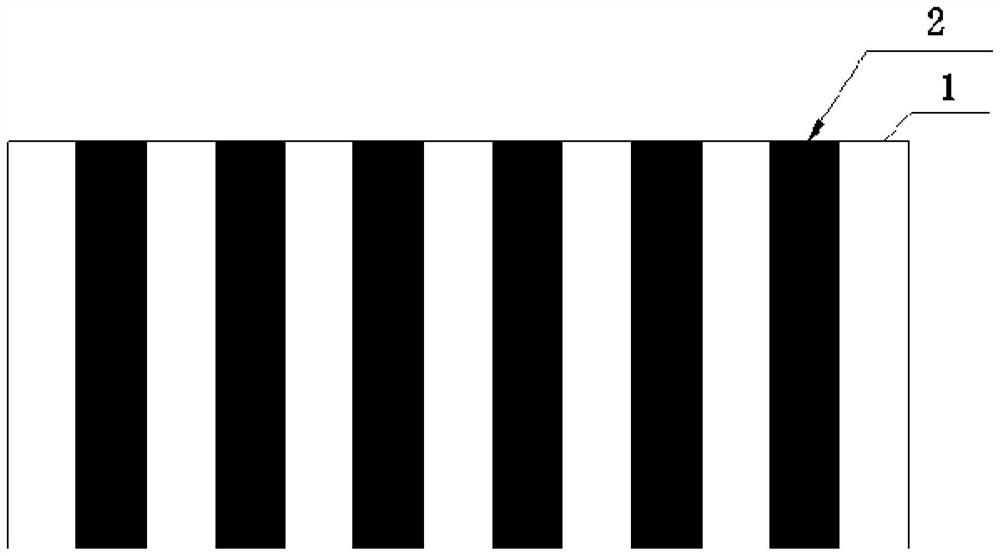

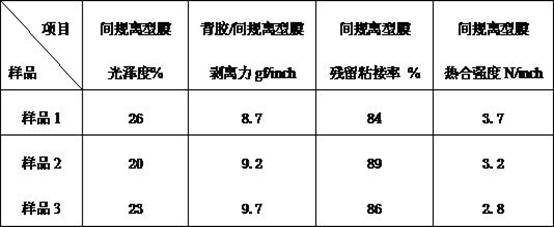

[0026] The syndiotactic release film is a self-made material, including a non-release area (1) and a release area (2). Its preparation method is as follows: step 1, weigh 0.5wt% antistatic agent Irgastat P18 (Basf), 20wt% matting resin FB2230 (Borealis), 70wt% metallocene resin 5101 (Dow Chemical), 9.5wt% 2045G (Dow Chemical) Mixed evenly by mixer, marked as 1-non-releas...

Embodiment 2

[0029] A disposable absorbent article comprising, from top to bottom, a liquid-permeable topsheet, an absorbent core, a liquid-impervious backsheet, and a syndiotactic release film.

[0030] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0031] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0032] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

[0033] The syndiotactic release film is a self-made material, including a non-release area (1) and a release area (2). Its preparation method is as follows: step 1, weighing 1.0wt% antistatic agent Irgastat P18 (Basf), 40wt% matting resin FB2230 (Borealis), 19wt% 2049P (Dow), 40wt% metallocene resin EXCEED 1018 ( Exxon) is mixed evenly by a mixer, and it is marked as 1-n...

Embodiment 3

[0036] A disposable absorbent article comprising, from top to bottom, a liquid-permeable topsheet, an absorbent core, a liquid-impervious backsheet, and a syndiotactic release film.

[0037] The material of the liquid-permeable top layer is air-through non-woven fabric with a specification of 168mm*20gsm, purchased from Yanjiang Company.

[0038] The absorbent core is dust-free paper with a specification of 168mm*60gsm, purchased from Tianjin BBA Company.

[0039] The liquid-impermeable bottom layer is a gas-permeable film with a specification of 168mm*35gsm, which is purchased from Korea Hans Corporation.

[0040] The syndiotactic release film is a self-made material, including a non-release area (1) and a release area (2). The preparation method is as follows: Step 1. Weigh 1.5wt% antistatic agent Irgastat P18 (Basf), 30wt% matting resin FB2230 (Borealis), 33.5wt% 1002kw (Exxon), 35wt% MarFlex D139 and mix them in a mixer Uniform, identified as 1-non-release zone material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com