Method for removing electrostatic charges on surface of wafer

An electrostatic charge and wafer technology, applied in the field of semiconductor manufacturing, can solve problems such as wafer defects, wafer surface electrostatic charge cannot be effectively removed, scrapped, etc., and achieve the effect of preventing electrostatic breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

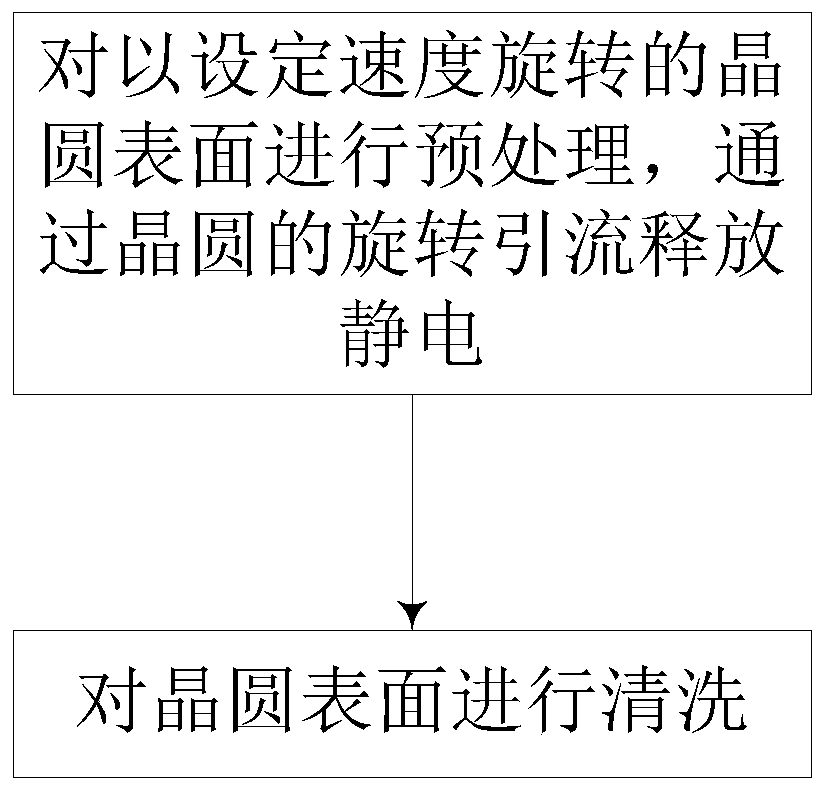

[0024] In this embodiment, the method for removing static charge on the wafer surface, such as figure 1 shown, including the following steps:

[0025] Step S1, pretreat the surface of the wafer rotating at a set speed, and discharge static electricity through the rotation and drainage of the wafer;

[0026] Step S2, cleaning the surface of the wafer.

[0027] Wherein, in step S1, the set speed of the wafer rotation is less than 80 rpm.

[0028] In this embodiment, atomized water or atomized isopropyl alcohol (IPA) is sprayed on the surface of the rotating wafer for pretreatment, and the static charge on the surface is taken away by the rotation of the wafer, and the rotation speed of the wafer can be controlled. Prevent electrostatic breakdown, and then slowly clean the wafer surface with ultra-low resistance water or diluent, so as to completely remove the electrostatic charge on the wafer surface.

Embodiment 2

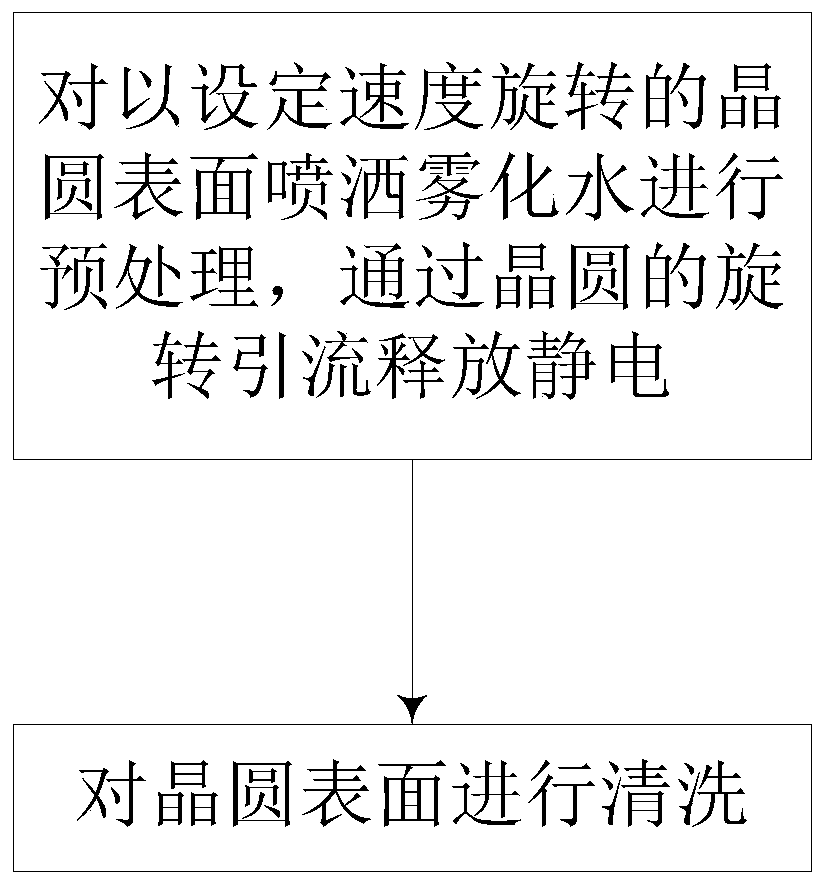

[0030] In this embodiment, the method for removing static charge on the wafer surface, such as figure 2 As shown, the difference from Embodiment 1 is that in step S1, atomized water is sprayed on the surface of the wafer for pretreatment.

Embodiment 3

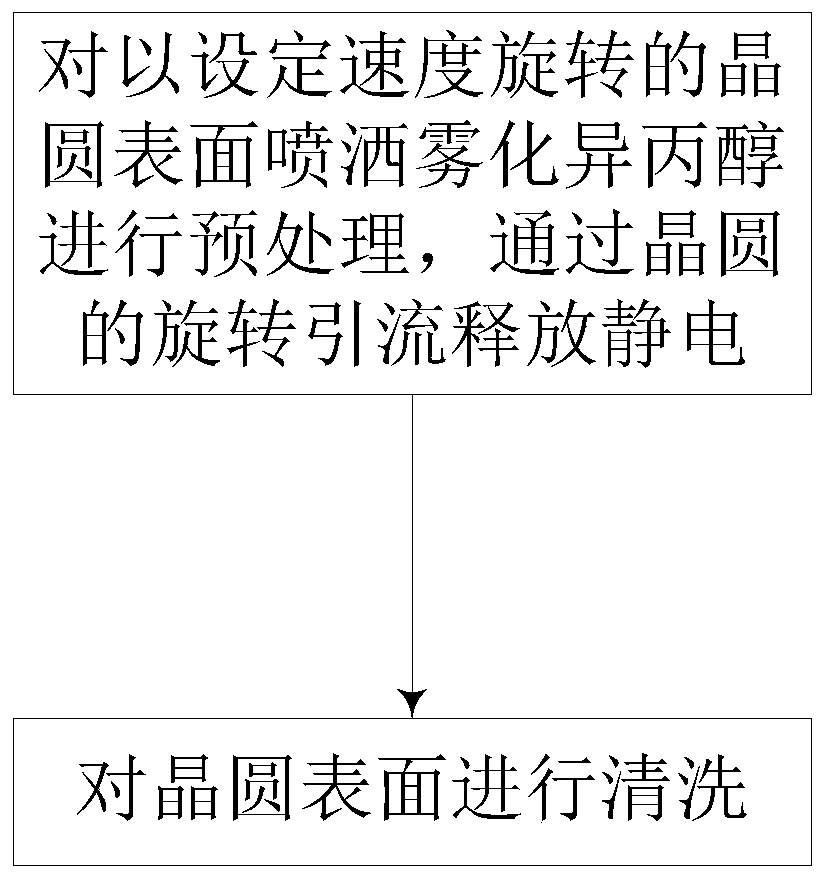

[0032] In this embodiment, the method for removing static charge on the wafer surface, such as image 3 As shown, the difference from the first embodiment is that in step S1, atomized isopropanol (IPA) is sprayed on the surface of the wafer for pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com