Anti static circle of suction and collection in use for tighness spinning

An anti-static and compact technology, applied in the field of poly-absorbing rings, can solve problems such as uneven fiber dryness, blockage of air holes in the poly-absorbing ring, failure of the poly-absorbing ring, etc., so as to improve the ventilation efficiency and service life, improve the synchronization effect, The effect of eliminating static charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

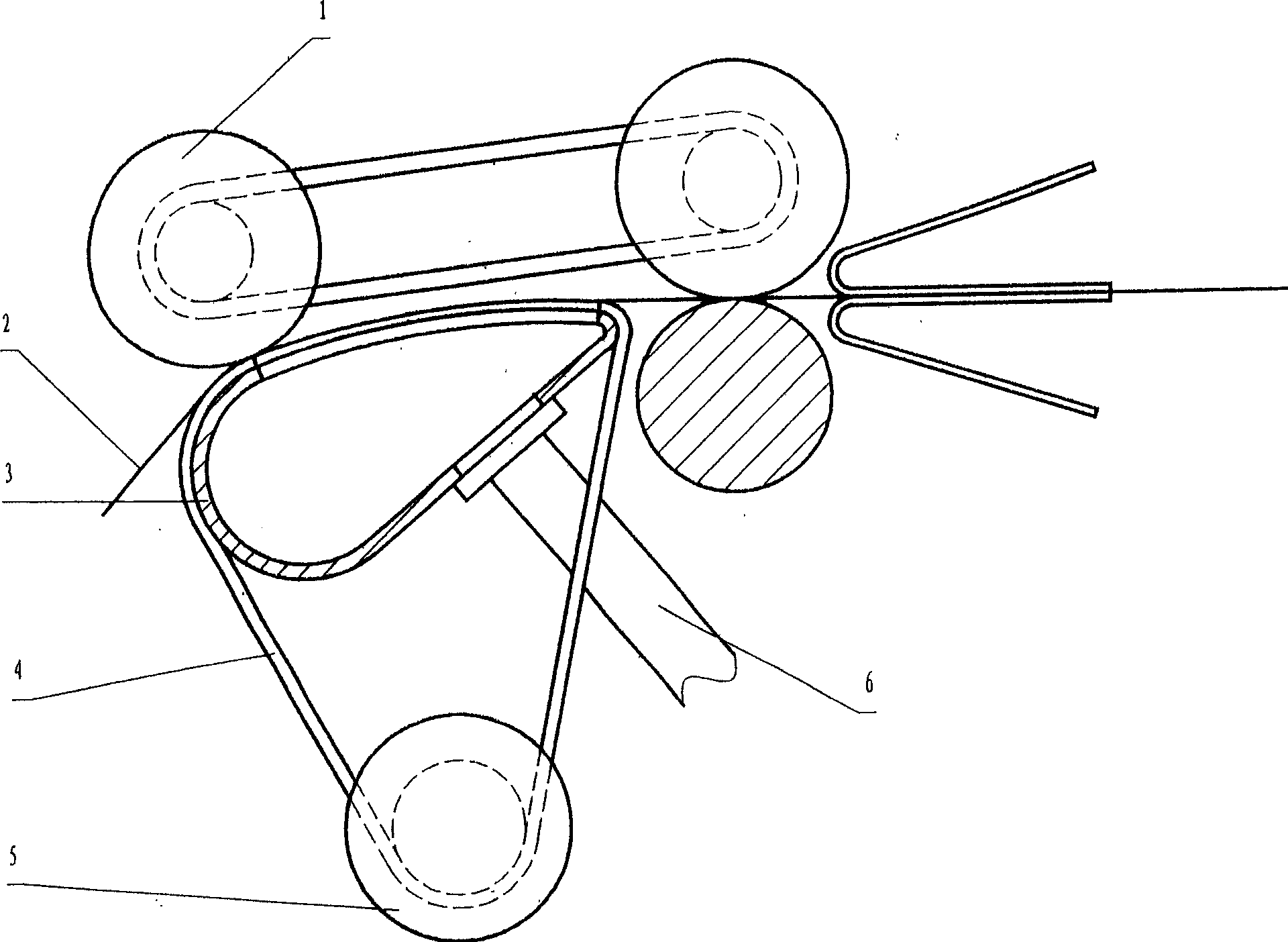

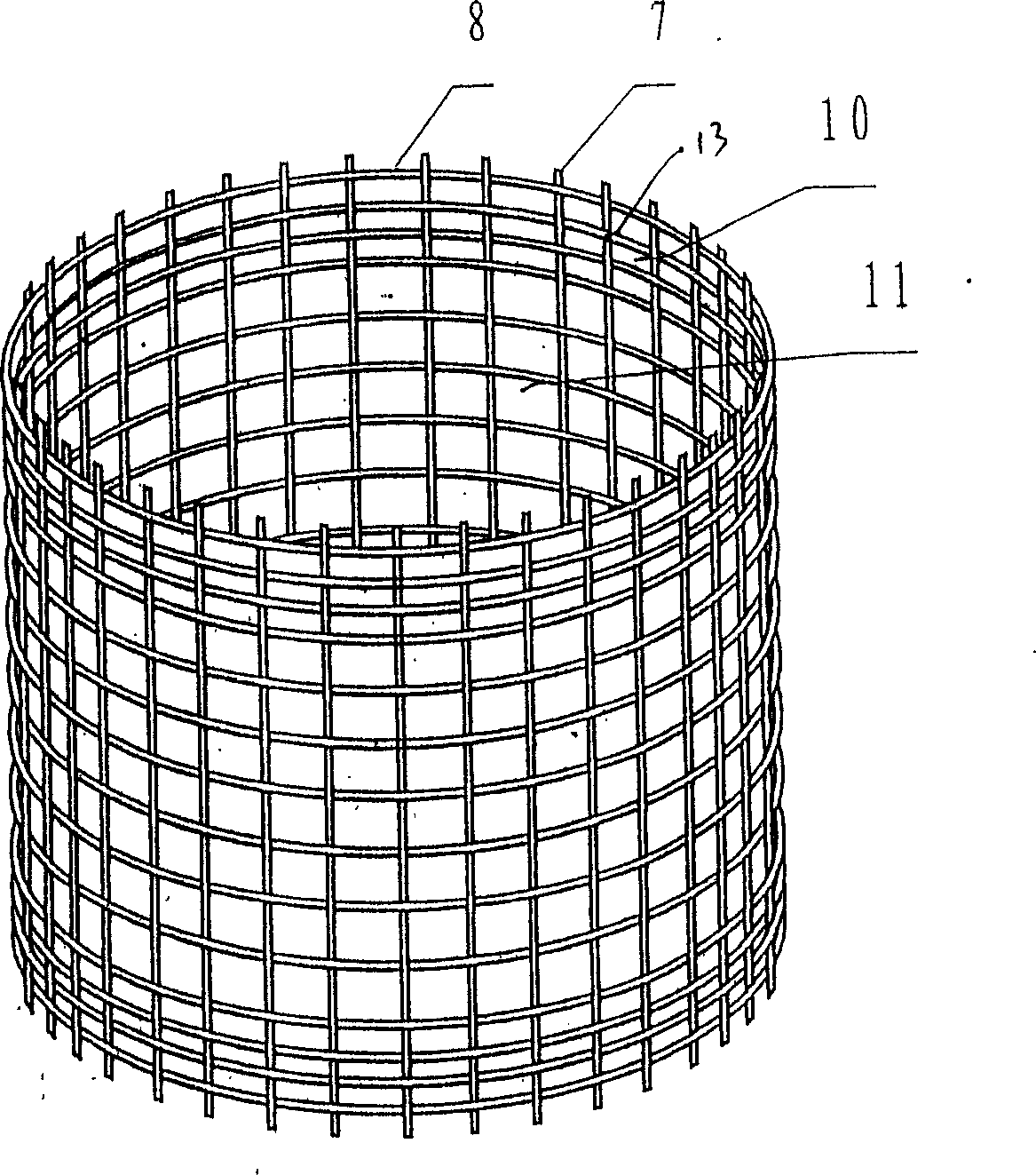

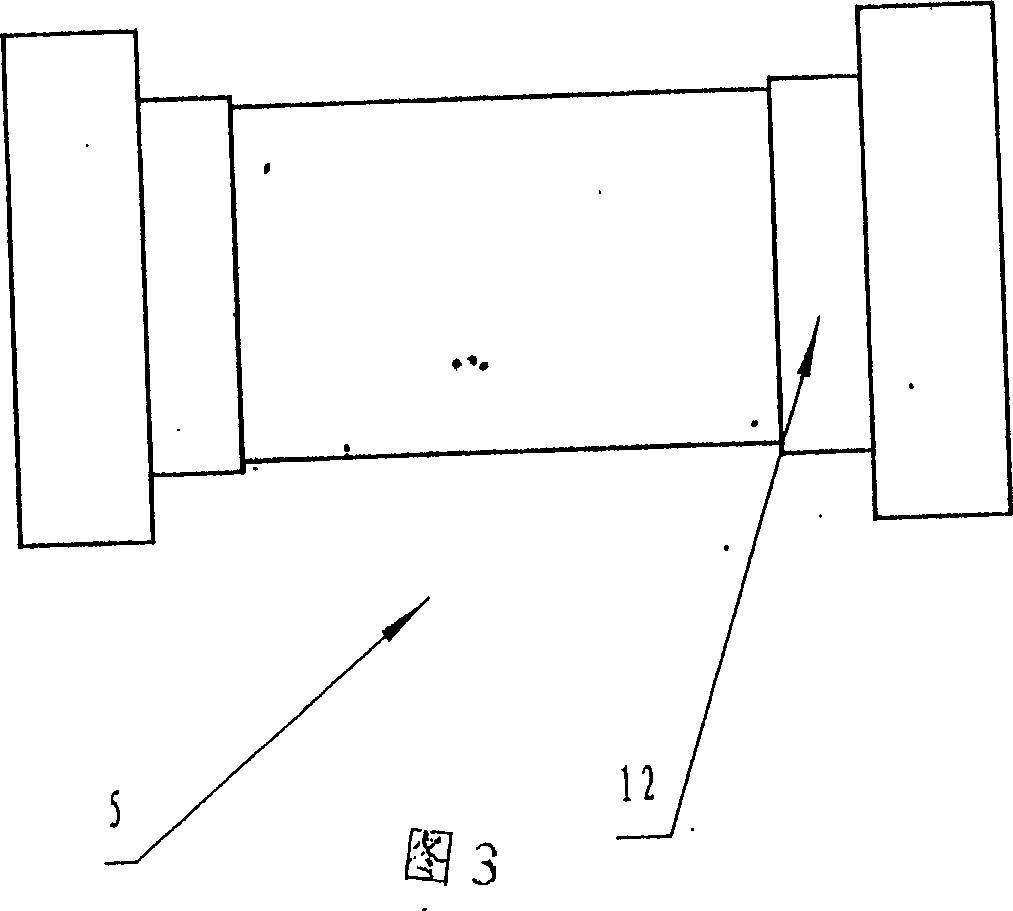

[0015] As shown in the figure: the gathering ring 4 is woven into a tubular shape by warp threads 7 and weft threads 8, and at least one of the warp threads or / and weft threads is a conductive fiber. The gathering ring 4 is driven by the traction wheel 5, and a transmission zone 10 for transmission is set at both ends of the tubular gathering ring 4. The performance characteristics of the transmission zone 10 are: its hardness will be greater than that of the gathering zone 11 located in the middle, It is also possible that its thickness will be greater than that of the gathering-absorbing zone 11 located in the middle, so that when the traction pulley 5 drives the gathering-absorbing ring 4 to rotate, good synchronization performance will be provided. In the middle part of the absorbing ring 4, the absorbing zone 11 which plays the role of absorbing is set, and the holes interwoven by warp and latitude threads are densely covered in the absorbing zone 11. The effect of the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com