Self-adaption clamp suitable for complex hook face machining and use method of self-adaption clamp suitable for complex hook face machining

A complex curved surface, self-adaptive technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low work reliability, small scope of application, high cost of fixture production, etc., to achieve high work reliability and applicable The effect of wide range and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

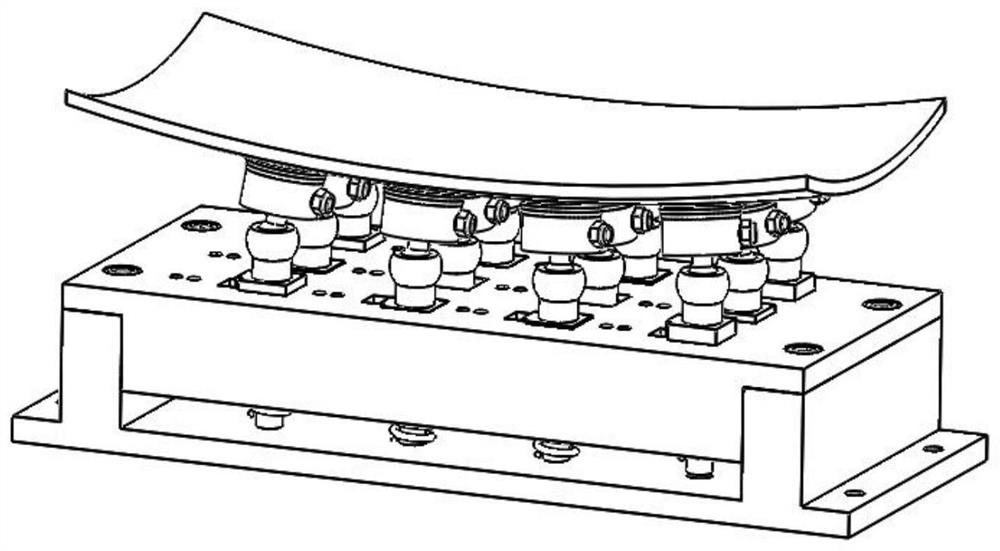

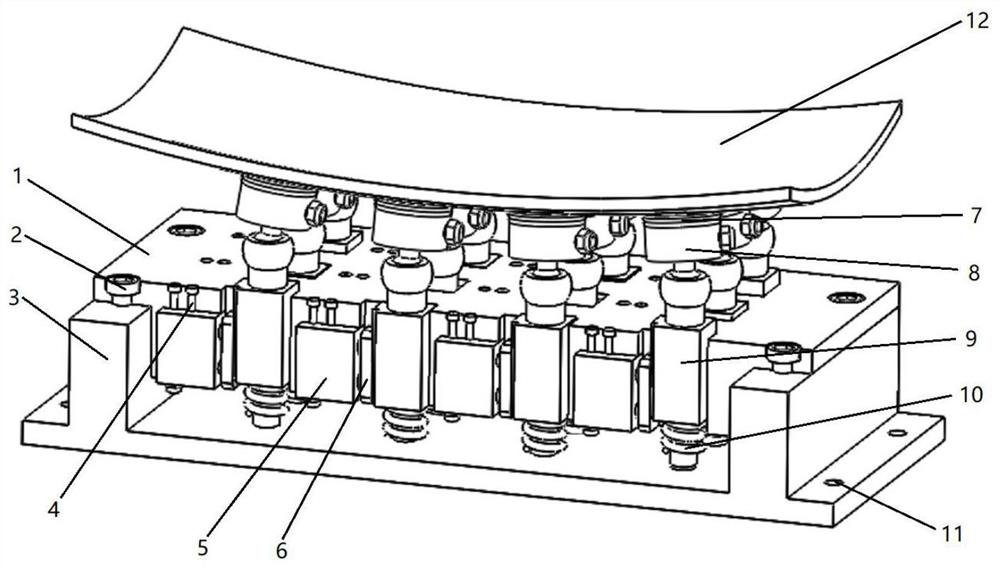

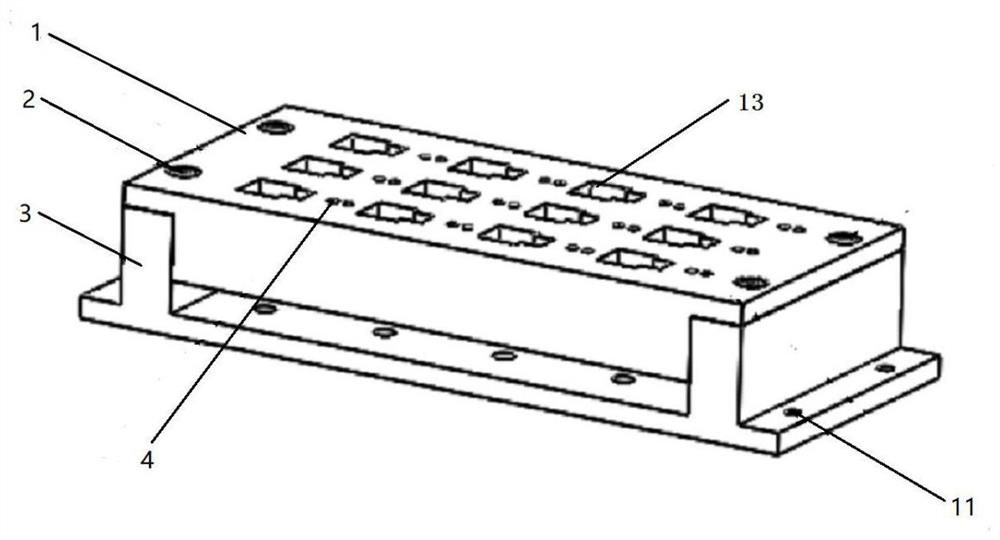

[0042] An adaptive fixture suitable for complex curved surface processing includes a fixing device and a clamping device.

[0043]The fixing device is composed of a fixing frame 1 and a bottom plate 3, and the two are assembled by four identical fixing screws 2. The clamping device is made up of sealing sleeve 7, sucker 8, slide bar 9, spring 10, pneumatic cylinder 5 and piston 6 of equal quantity, and this equal quantity is 12. Wherein the piston 6 is installed on the pneumatic cylinder 5, which can realize the reciprocating linear motion of the piston. There is an air suction pipe on the suction cup 8, which is used to suck the curved surface tightly. The suction cup 8 is connected with the slide bar 9 through a ball joint, which can realize the arbitrary rotation of the suction cup within a certain angle. After many groups of suction cups 8 and slide bars 9 are installed, they are evenly installed in the chute 13 of the fixed mount 1. Pneumatic cylinder 5 cooperates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com