Upper die-cutting plate of die-cutting machine and die-cutting machine

A die-cutting machine and die-cutting board technology, applied in metal processing and other directions, can solve the problems of the movement of the printed cardboard, the limited stroke of the backing plate, and the position that affects the indentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

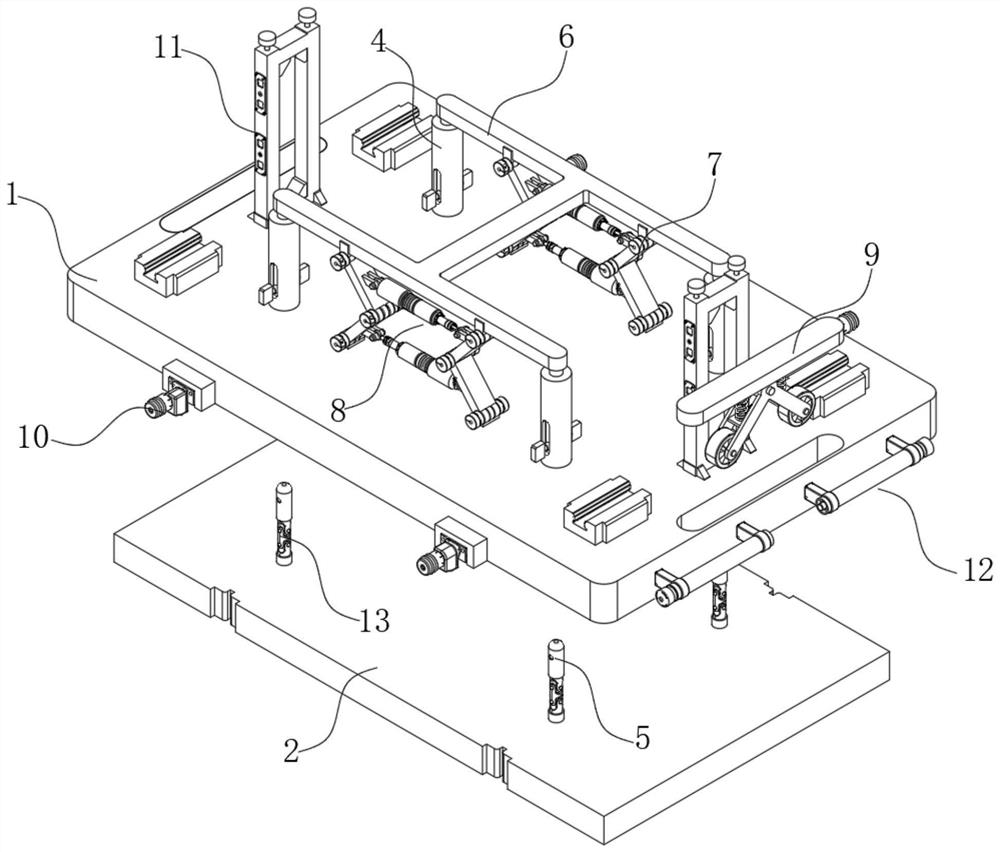

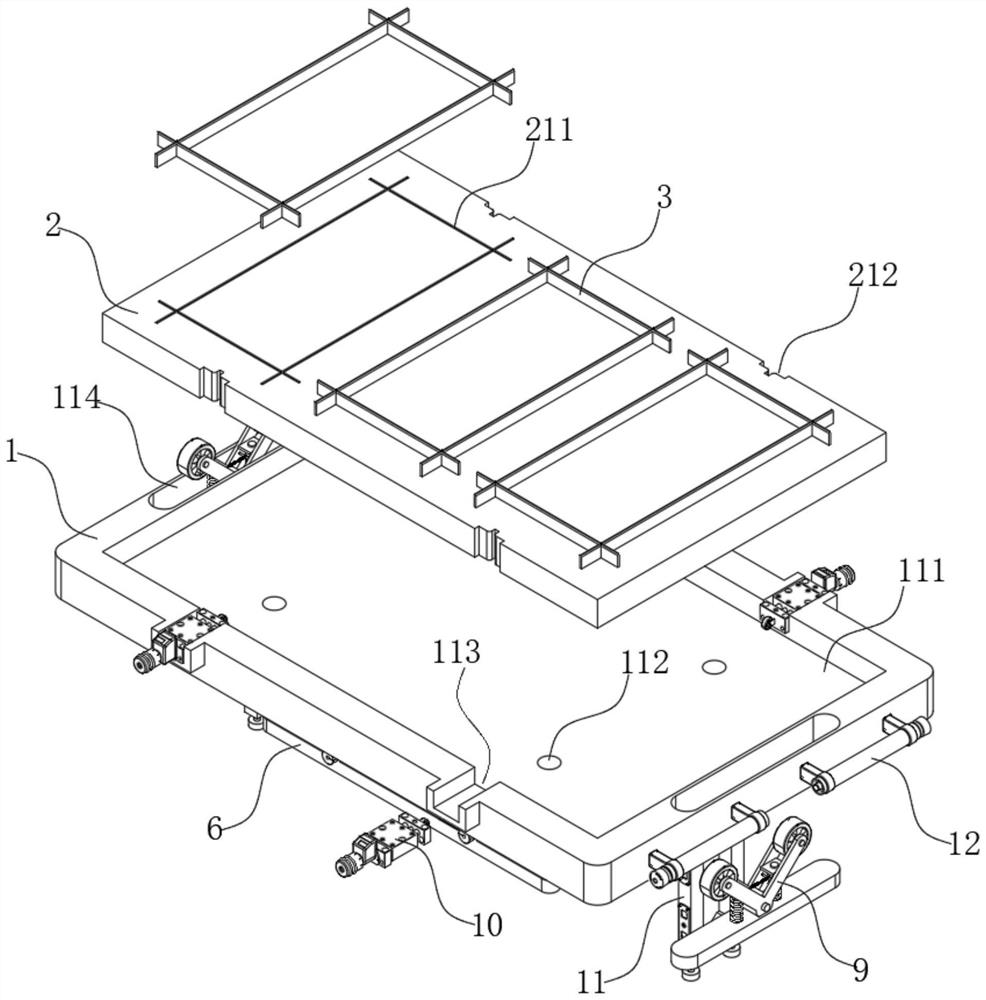

[0035] see Figure 1 to Figure 10 , the present invention provides a technical solution:

[0036] An upper die-cutting plate of a die-cutting machine, comprising a die-cutting frame body 1, a die-cutting blade plate 2, a die-cutting knife 3, a pressure supplement assembly 4, a fixing rod 5, a connecting rod assembly 6, a double toggle assembly 7, a damping Rod 8, platen assembly 9, interference assembly 10, connection assembly 11, handle 12 and universal joint 13, wherein:

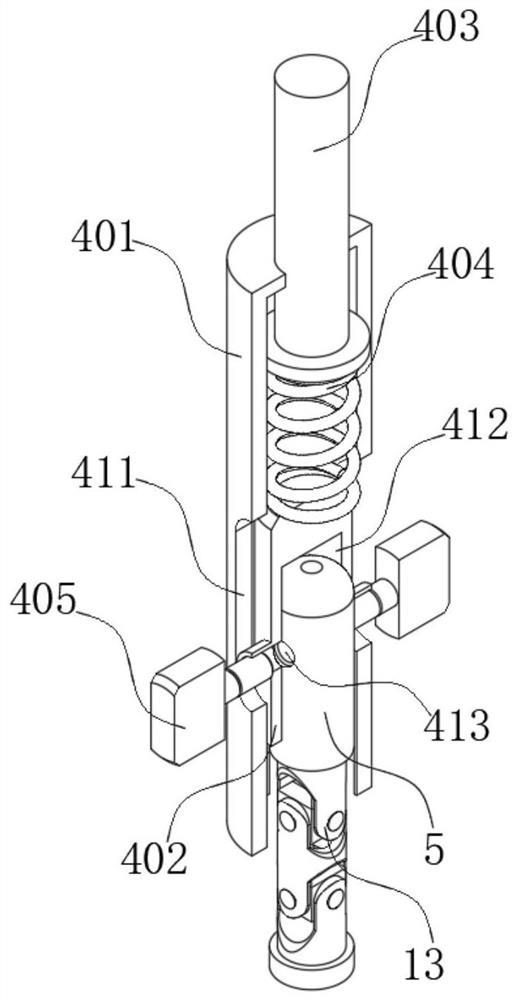

[0037]The lower end surface of the die-cutting frame body 1 is provided with a concave mounting groove 111, and the upper end surface of the mounting groove 111 is provided with a mounting hole 112 penetrating the die-cutting frame body 1, and the mounting hole 112 is fixed with The pressure supplement assembly 4, the pressure supplement assembly 4 is composed of a fixed cylinder 401, an installation cylinder 402, a lifting rod 403, a pressure supplement spring 404 and a fixed screw rod 405, the fixed cyl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap