Methods for controlling warehousing, delivery and inventory of materials and material management system

A material warehouse and material technology, which is applied in the field of warehouse management, can solve the problems of high work intensity, long travel routes, and high labor costs of the staff, and achieve the effects of reducing the time of leaving the warehouse, improving work efficiency, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

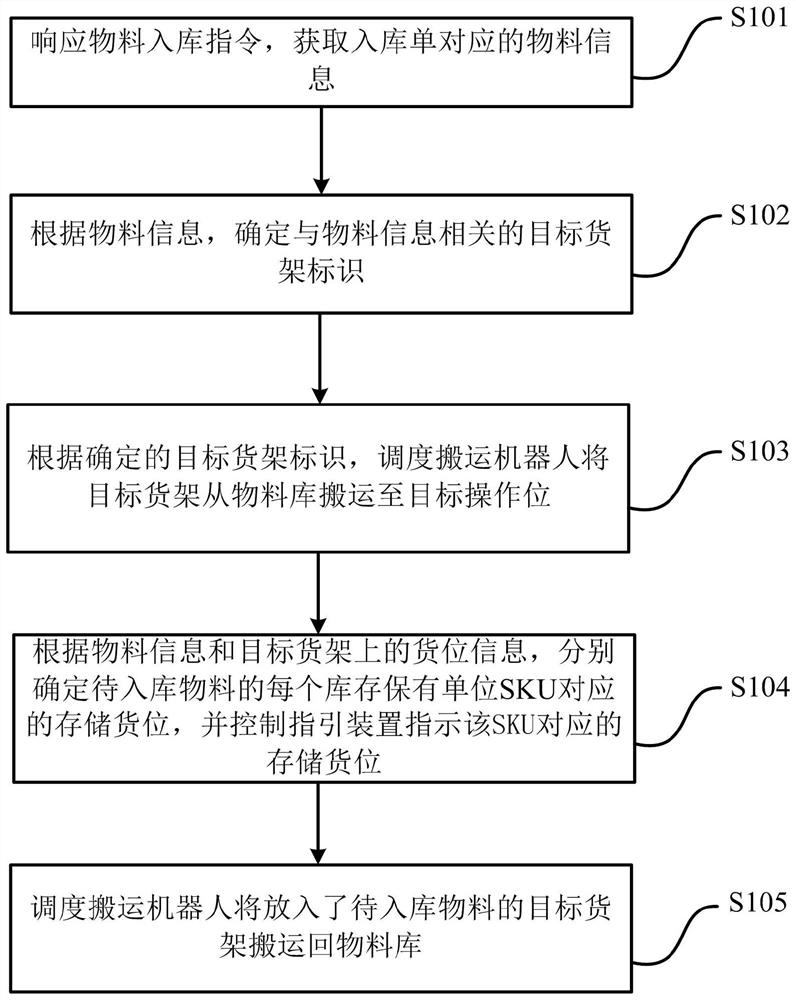

[0062] In the specific implementation, take the management of orthopedic consumables as an example: the operation center sends the required consumables list information to the consumables warehouse management system a few days before the operation day, and the staff of the consumables warehouse checks the received consumables list information, and according to the received The received consumables list information checks whether the consumables in the consumables library are complete. When the consumables are not complete, the information on the consumables to be purchased will be sent to the hospital procurement system. The purchased consumables information is sent to the consumables warehouse management system. The consumables warehouse management system generates a storage order based on the received purchased consumables information. The staff puts the corresponding consumables into the warehouse based on the above storage order. The specific storage process is as follows D...

Embodiment 2

[0089] In the specific implementation, taking orthopedic consumables as precision goods as an example: the operation center sends the required consumables list information to the consumables warehouse management system a few days before the operation day, and the staff of the consumables warehouse checks the received consumables list information, and according to the received The received consumables list information checks whether the consumables in the consumables warehouse are complete. When the consumables are complete, the consumables warehouse management system will generate an outbound order based on the consumables list information. The staff will deliver the corresponding consumables out of the warehouse based on the above outbound order. The specific outbound process For details, please refer to the following outbound steps.

[0090] refer to Figure 4 The above is a flow chart of a method for controlling material outbound provided by an embodiment of the present dis...

Embodiment 3

[0112] In the specific implementation, the staff can choose to count the materials in the material library according to the needs of the supplier, or choose to directly carry out the inventory of the whole library; in the above two inventory methods, you can choose to count by quantity or by the identification of the material code for inventory. When the staff selects the supplier according to the demand to count the materials in the material library according to the quantity, the specific inventory process is detailed in the following inventory steps.

[0113] refer to Figure 7 The above is a flow chart of a method for controlling material inventory provided by an embodiment of the present disclosure, the method includes steps S701 to S704, wherein:

[0114]S701. Obtain target supplier information in response to a material inventory instruction.

[0115] Among them, the target supplier information is all material information in the material library of the supplier that nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com