Pretreatment filling liquid applied to artificial inorganic stone and its pretreatment method and application

A technology of pretreatment and filling liquid, which is applied in the direction of manufacturing tools, polishing compositions containing abrasives, metal processing equipment, etc. It can solve the problems of reducing the durability and quality of products, affecting the appearance of products, and being intolerant of high temperature, and reducing micro-cracks. The effect of producing, increasing the density of the cured product, and reducing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13 and comparative example 1-2

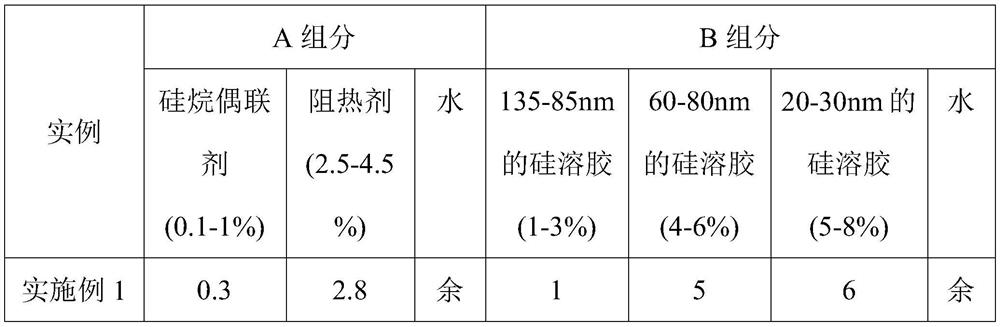

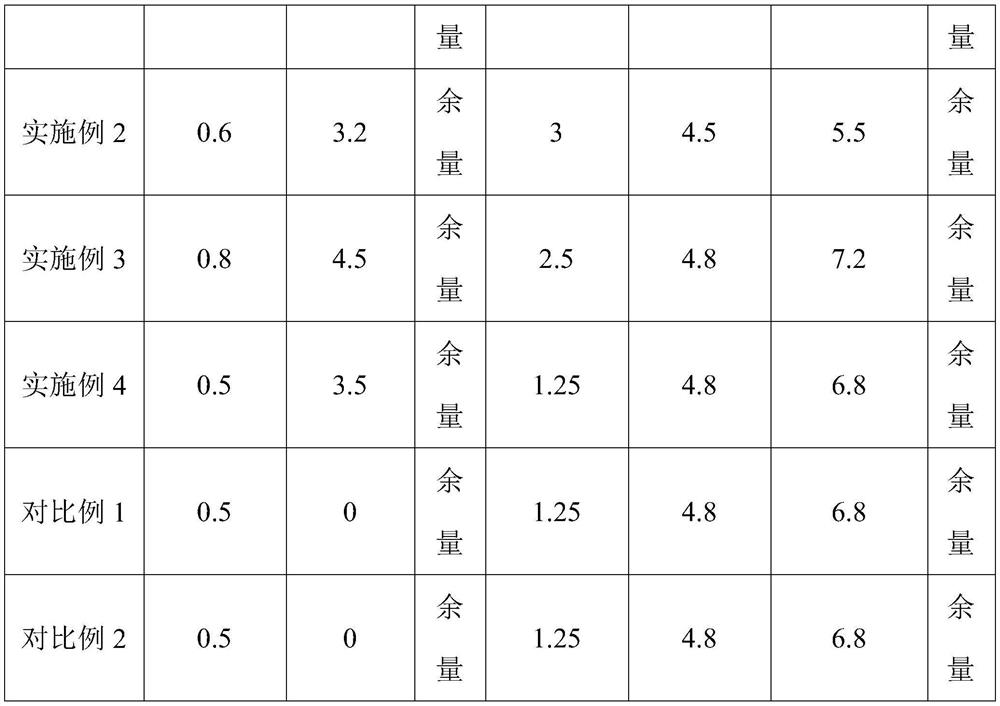

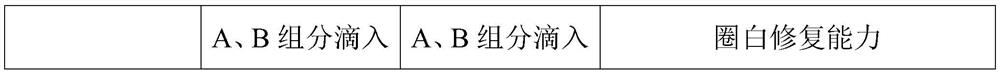

[0060] Take each component according to the formula in Table 1 below, and prepare the pretreatment filling fluids applied to artificial inorganic stones of Examples 1-13 and Comparative Examples 1-2 respectively, and then take the same batch of filling fluids produced by a company on the market. For artificial inorganic stone, the above-mentioned artificial inorganic stone is pretreated with the same pretreatment method using the pretreatment filling solution of Examples 1-13 and Comparative Example 1-2 respectively, and then super clean and bright treatment is carried out using the same grinding and polishing process, Then after placing it for 2 months, observe the surface of these 15 groups of treated artificial inorganic stones to see if they exist, and detect the surface luminosity value of the artificial inorganic stones. The specific results are shown in the table:

[0061] Table 1 is the formula composition of each embodiment pretreatment filling liquid

[0062]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com