Forward and reverse scouring dredging method for diversion canal of hydropower station and diversion canal structure

A diversion canal, forward and reverse technology, applied in the field of hydropower station diversion canal forward and reverse scouring and dredging methods and diversion canal structure, can solve problems such as time-consuming, laborious, insufficient diversion flow for power generation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

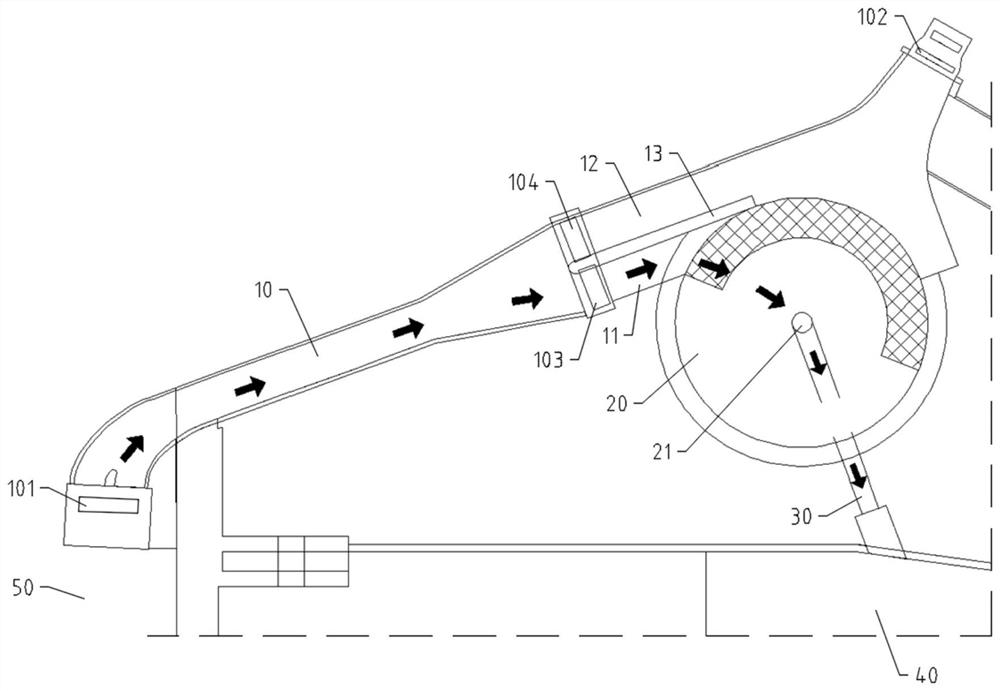

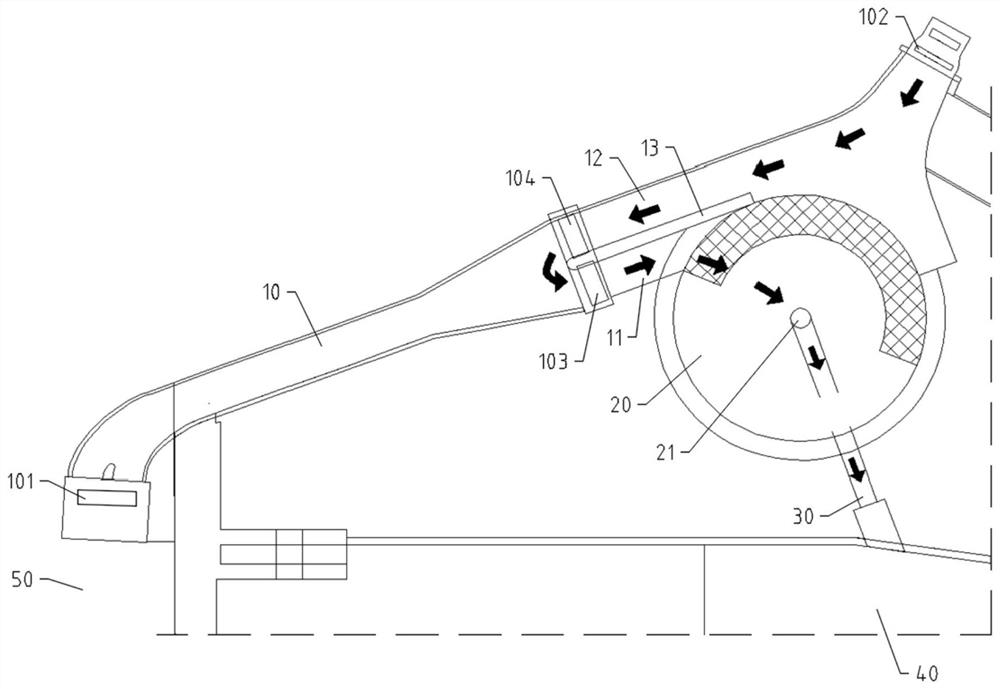

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] The invention provides a hydropower station diversion canal forward and reverse scouring dredging method, comprising the following steps:

[0040] Step S10, determine the gradation of the silt in the diversion channel 10 by screening with a vibrating sieve or measuring with a laser particle size analyzer;

[0041] Specifically, to wash away the sediment by water flow, it is first necessary to determine the gradation of the sediment, that is, the distribution of sediment particles of different particle sizes in the sediment. The determination of gradation can be carried out by selecting a vibrating sieve with a certain mesh number to sieve the silt and sediment, or by using a laser particle size analyzer for direct measurement.

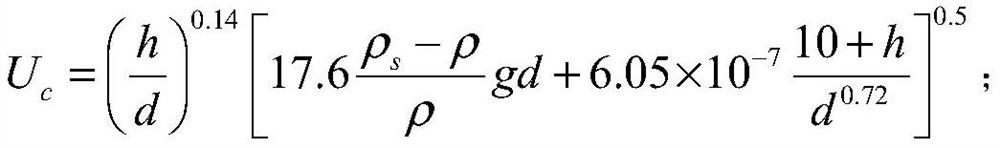

[0042] Step S20, according to the gradation curve of the silt and sand, using the silt particle size corresponding to d90 on the gradation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com