Ground seam beautifying device

A technology of beautiful seams and ground, applied in the direction of architecture, building structure, etc., to achieve the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

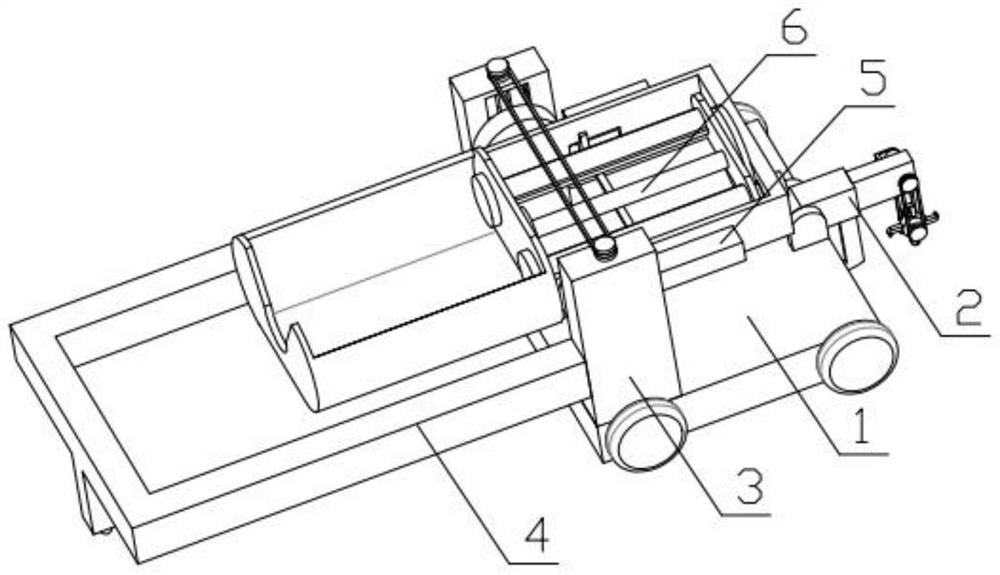

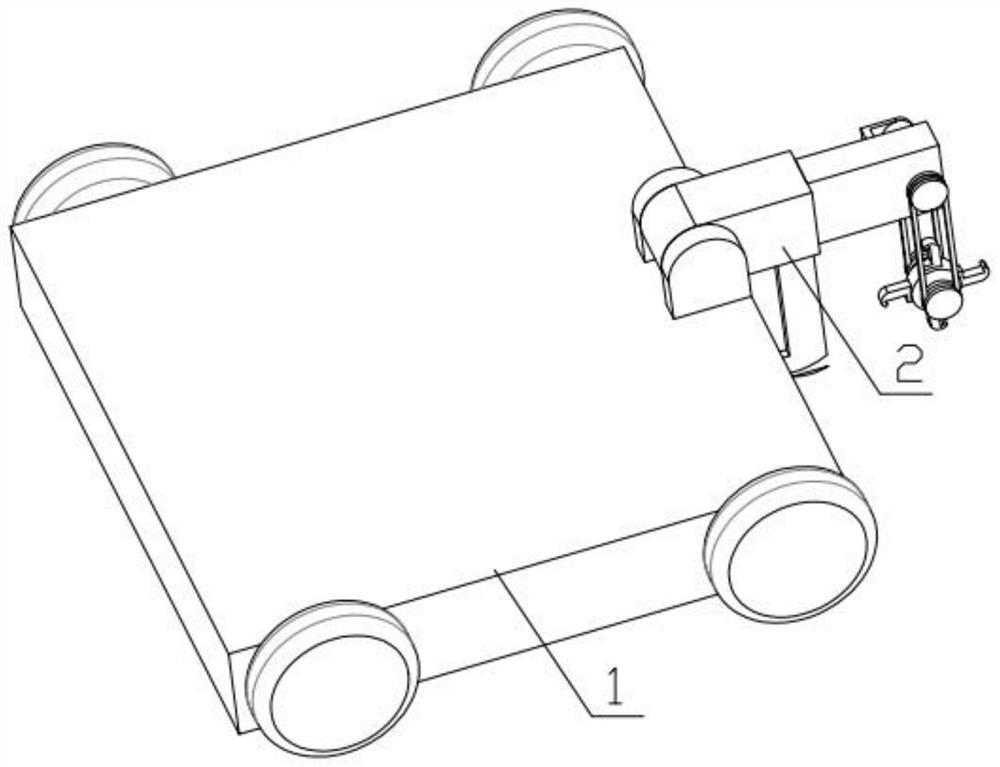

[0037] Combine below Figure 1-17 Description of this embodiment, a ground beautifying seaming device, including a moving mechanism 1, a cleaning and limiting mechanism 2, an angle adjustment mechanism 3, a seam pressing mechanism 4, an angle fixing mechanism 5 and a discharge mechanism 6, the cleaning and limiting mechanism The positioning mechanism 2 is hinged on the moving mechanism 1, the moving mechanism 1 is fixedly installed with an angle adjustment mechanism 3, the angle adjustment mechanism 3 is fixedly installed with a sewing mechanism 4, and the angle adjustment mechanism 3 is fixedly installed with a discharge mechanism 6. An angle fixing mechanism 5 is fixedly installed on the mechanism 6, and the angle fixing mechanism 5 is engaged with the angle adjusting mechanism 3.

specific Embodiment approach 2

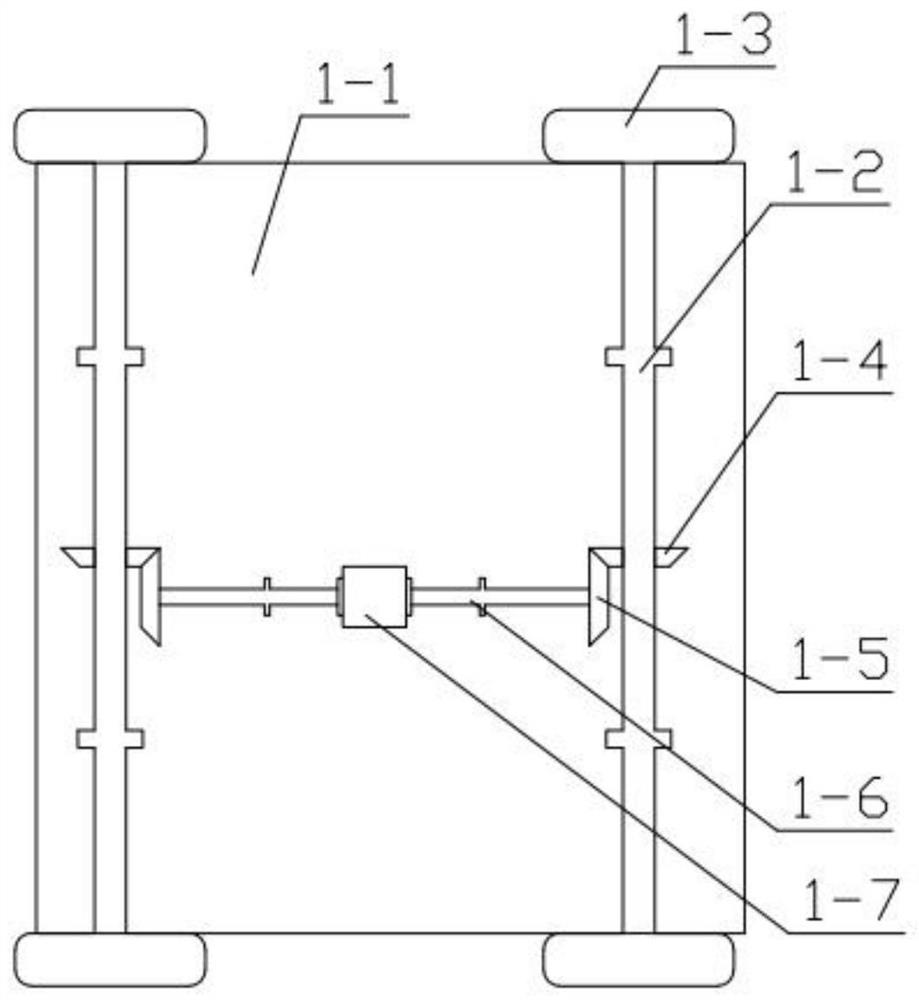

[0039] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the moving mechanism 1 includes a bottom plate 1-1, a roller shaft 1-2, a roller 1-3, a helical gear ring 1-4, and a helical gear 1-5 , connecting rod 1-6, bidirectional output motor 1-7, bidirectional output motor 1-7 is fixedly installed in the groove provided on the base plate 1-1, and the output end of bidirectional output motor 1-7 is fixedly installed with connecting rod 1-7 6. The connecting rod 1-6 is rotatably installed in the groove provided on the bottom plate 1-1, the other end of the connecting rod 1-6 is fixedly installed with a helical gear 1-5, the helical gear 1-5 and the helical gear ring 1-4 The helical gear ring 1-4 is fixedly installed on the roller shaft 1-2, and the roller shaft 1-2 is rotatably installed in the groove provided on the bottom plate 1-1, and the two ends of the roller shaft 1-2 are respectively fixedly installed with Roll...

specific Embodiment approach 3

[0041] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the second embodiment, the cleaning and limiting mechanism 2 includes a hinged joint 2-1, a limiting plate 2-2, an L-shaped connecting plate 2-3, a motor 2 -4, double sprocket part 2-5, chain 2-6, sprocket one 2-7, sprocket two 2-8, belt hook round part 2-9, hinge joint 2-1 is hinged with base plate 1-1 , the hinged joint 2-1 is fixedly connected with the limit plate 2-2, the hinged joint 2-1 is fixedly mounted with an L-shaped connecting plate 2-3, and the L-shaped connecting plate 2-3 is fixedly mounted with a motor one 2-4, The output end of motor one 2-4 is fixedly installed with double chain wheel part 2-5, and double chain wheel part 2-5 is rotatably installed in the groove that L-shaped connecting plate 2-3 is provided with, and double chain wheel part 2-5 Mesh with chain 2-6, chain 2-6 meshes with sprocket two 2-8, another chain 2-6 meshes with sprocket one 2-7, sprocket o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com