Expanding type separate layer fracturing packer with anchoring function

A layered fracturing and expansion technology, which is applied in the direction of sealing/isolation, production fluid, wellbore/well components, etc., can solve the problem that layered fracturing tools cannot be lowered, and reduce the risk of unblocking , increase the expansion ratio, improve the effect of pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

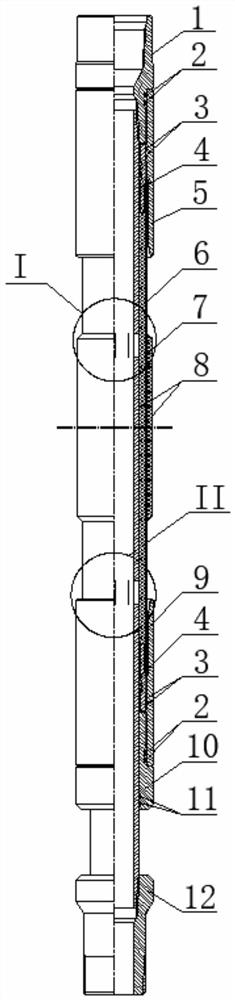

[0032] like figure 1 As shown, the center pipe 7 adopts a standard 2 3 / 8-P110 flat oil pipe, and the two ends of the center pipe 7 are respectively connected to the upper joint 1 and the lower joint 12 through 2 3 / 8 TBG oil pipe threads.

[0033] For the layered fracturing packer of the present invention, since the center pipe adopts the standard 2 3 / 8-P110 flat oil pipe, the center pipe meets the requirements of tightness and erosion resistance, so that the outer diameter of the packer is within the design Make it as small as possible, so that the packer can shrink the well section through casing deformation, and smoothly go down to the design well depth, so as to meet the needs of casing-variable well layered fracturing.

Embodiment 2

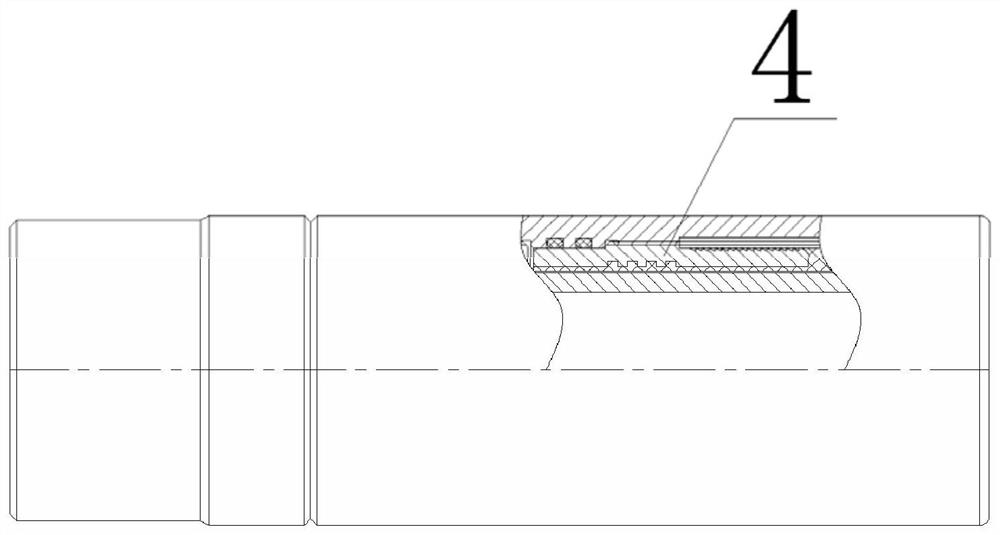

[0035] like figure 1 As shown, both ends of the steel strip 6 are pressed against the steel strip seat 4, and the material of the steel strip 6 is a stainless steel material with high elasticity and small residual deformation.

[0036] The layered fracturing packer of the present invention, because the steel strip is made of stainless steel with high elasticity and small residual deformation, can meet the requirement of high expansion ratio, and at the same time facilitate the extraction of the pipe string after fracturing.

Embodiment 3

[0038] On the basis of Example 2, the rubber tube 8 is divided into inner and outer layers, vulcanized on both sides of the steel belt 6 . The inner vulcanized rubber completely covers the steel belt seat 4 at both ends, the outer vulcanized rubber is shorter, and part of the steel belt is exposed; the steel belt seat 4 is respectively connected with the upper rubber barrel seat 5 and the lower rubber barrel seat 9 through threads, and the upper rubber barrel The seat 5 is fixed on the upper joint 1 through threaded connection, the lower rubber tube seat 9 is connected to the external thread of the floating head 10, the floating head 10 is passed on the central tube 7, and the smallest inner wall of the floating head 10 is provided with an apron groove, which can It forms a dynamic sealing fit with the outer wall of the central tube 7 to form a "floating down" compensation structure.

[0039] In the layered fracturing packer of the present invention, because the packer adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com