Air inlet test simulation device and simulation method

A technology of simulation device and simulation method, applied in the field of wind tunnel test, can solve the problems of poor test data quality and low test efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

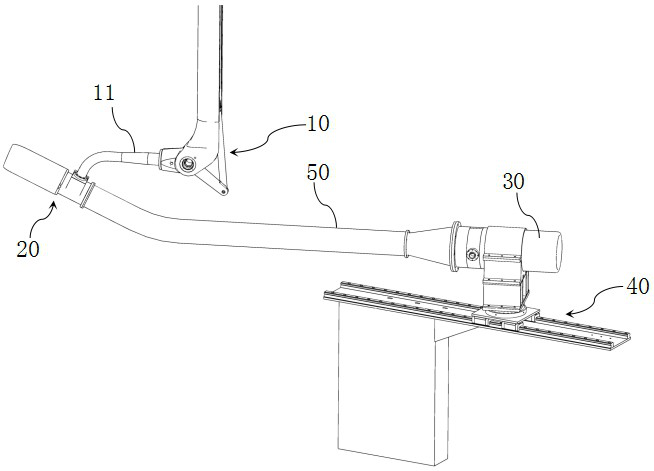

[0036] Such as figure 2 Shown is a schematic diagram of an inlet test simulation device in Embodiment 1 of the present invention, which includes: a model support assembly 10, a model support rod 11, a model 20, a flow simulator 30, a simulator support assembly 40, a flexible suction An air pipe 50, wherein the model support assembly 10 is connected to the outer periphery of the model 20 through the model support rod 11;

[0037] One end of the flexible suction pipe 50 is connected to the air outlet of the model 20, and the other end of the flexible suction pipe 50 is connected to the air inlet of the flow simulator 30;

[0038] The flow simulator 30 is supported on the simulator support assembly 40 , and the simulator support assembly 40 can be adaptively adjusted along with the adjustment of the model support assembly 10 .

[0039] When performing the intake port test simulation, the flow rate of the intake port of the model 20 is simulated by the flow simulator 30 .

[00...

Embodiment 2

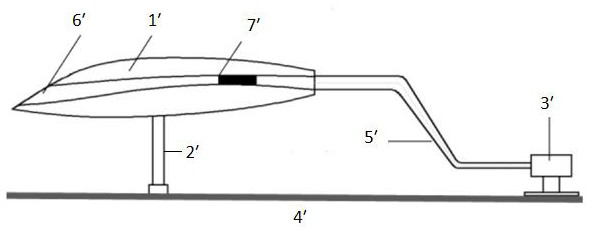

[0049] Such as Figure 4 Shown is a schematic diagram of an inlet test simulation method in Embodiment 2 of the present invention, which includes the following steps:

[0050] Step S10: arranging the above-mentioned inlet test simulation device in the wind tunnel test section;

[0051] Step S20: adjusting the model 20 so that the attitude angle of the model 20 meets the test requirements;

[0052] Step S30: Make the simulator support assembly 40 follow the movement;

[0053] Step S40: Carry out the air inlet test simulation.

[0054] Further, the step S20 adjusts the model 20 in the following manner: the model support assembly 10 drives the model 20 to move in X, Y, Z directions and rotate around the Y direction through the model support rod 11 .

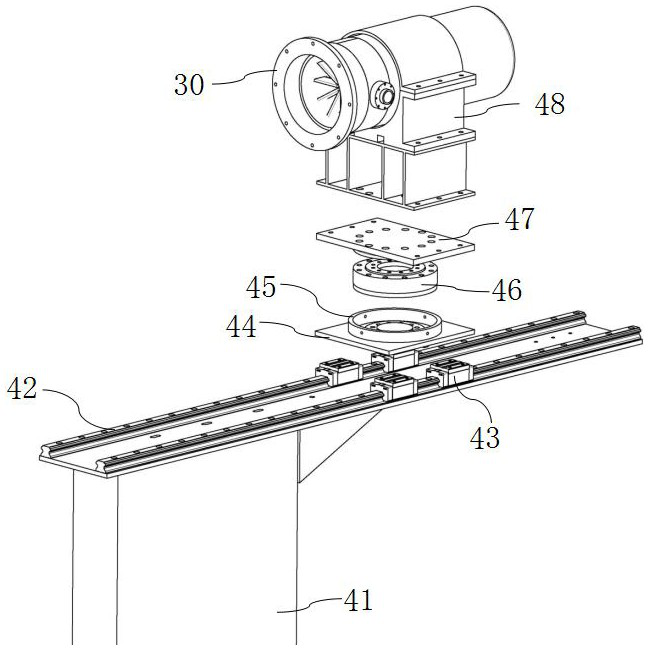

[0055] Further, the step S30 enables the simulator support assembly 40 to follow the movement in the following manner: the mobile support base 41 follows the movement in the Y and Z directions, the slider 43, the sliding connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com