A method for collimating solid-state light emitting chip or chip array light source

A solid-state light emitting and chip array technology, applied in the field of projection display, can solve the problems of increasing the difficulty of coating, unfavorable miniaturization, loss of light energy, etc., and achieve the effect of achieving collimation effect, increasing the scope of application, and improving the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

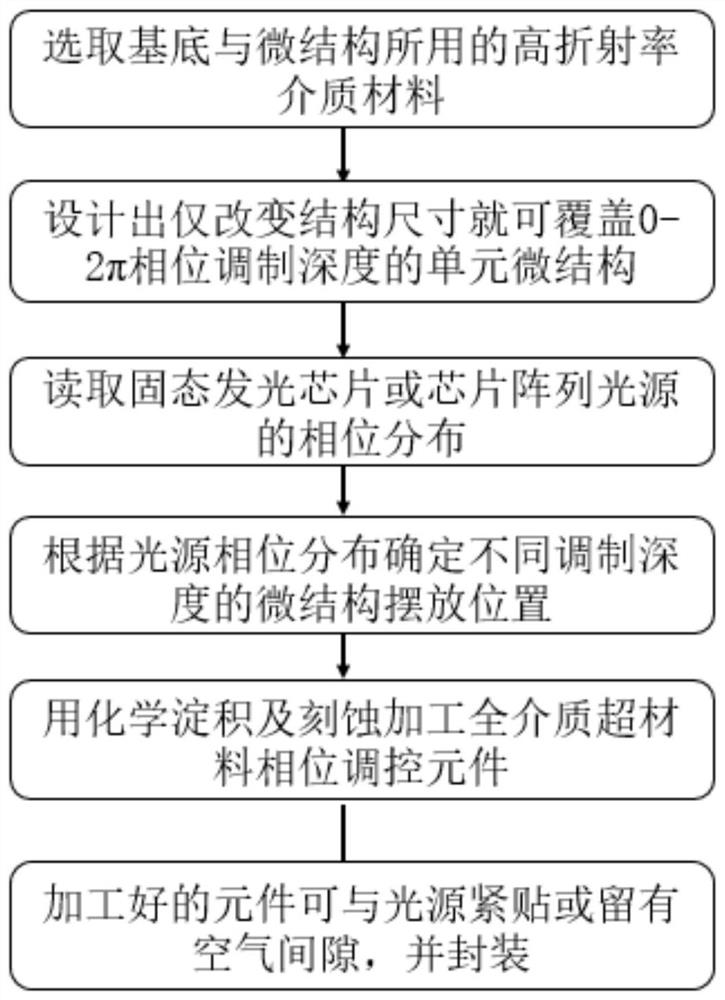

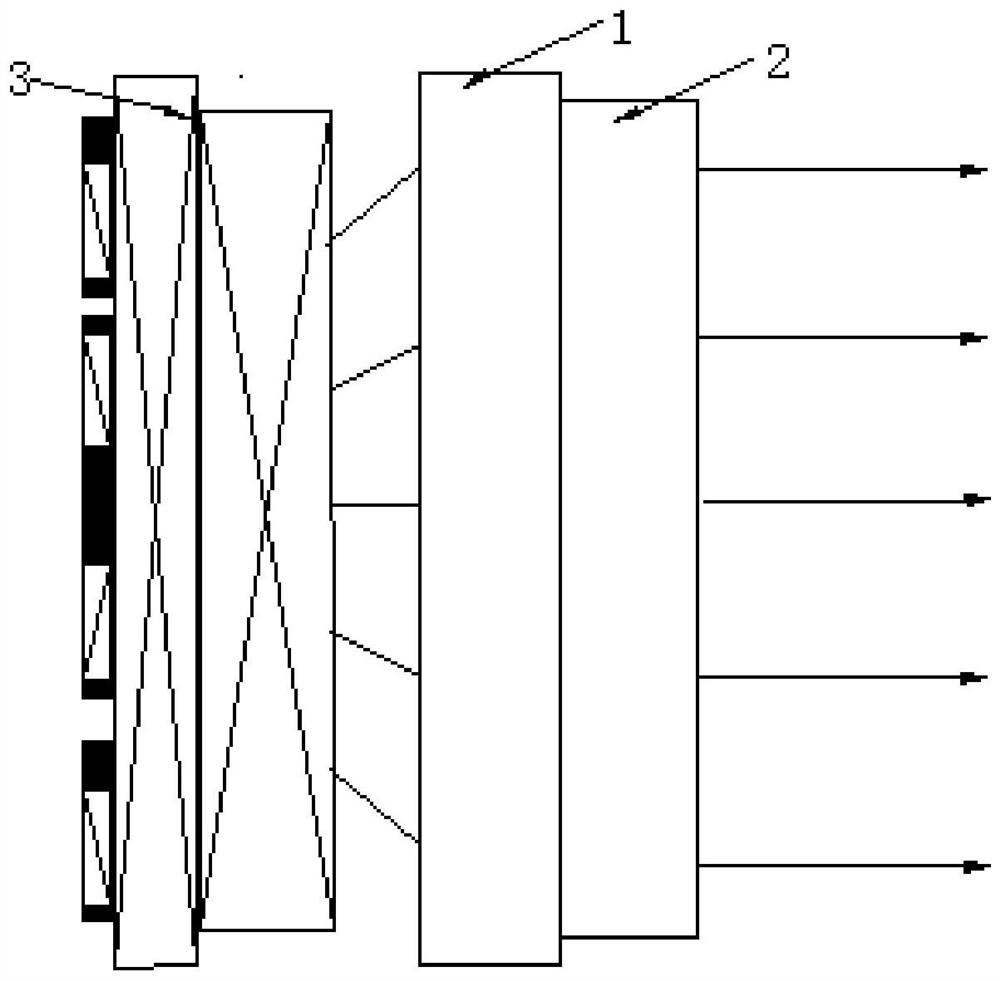

[0034] A method for collimating a solid-state light-emitting chip or a chip-array light source, by using an all-dielectric metamaterial phase control element to realize the collimation effect on a solid-state light-emitting chip or a chip-array light source, can eliminate the use of traditional lens components. Such as figure 1 As shown, it specifically includes the following steps:

[0035] Step 1. Select a dielectric material for making a substrate and a microstructure, and the substrate is used to support the microstructure.

[0036] Both the substrate and the microstructure of this solution use high-transmittance dielectric materials, so there is no need to coat them like lens groups to improve the light source transmittance.

[0037] Step 2. Design the microstructure.

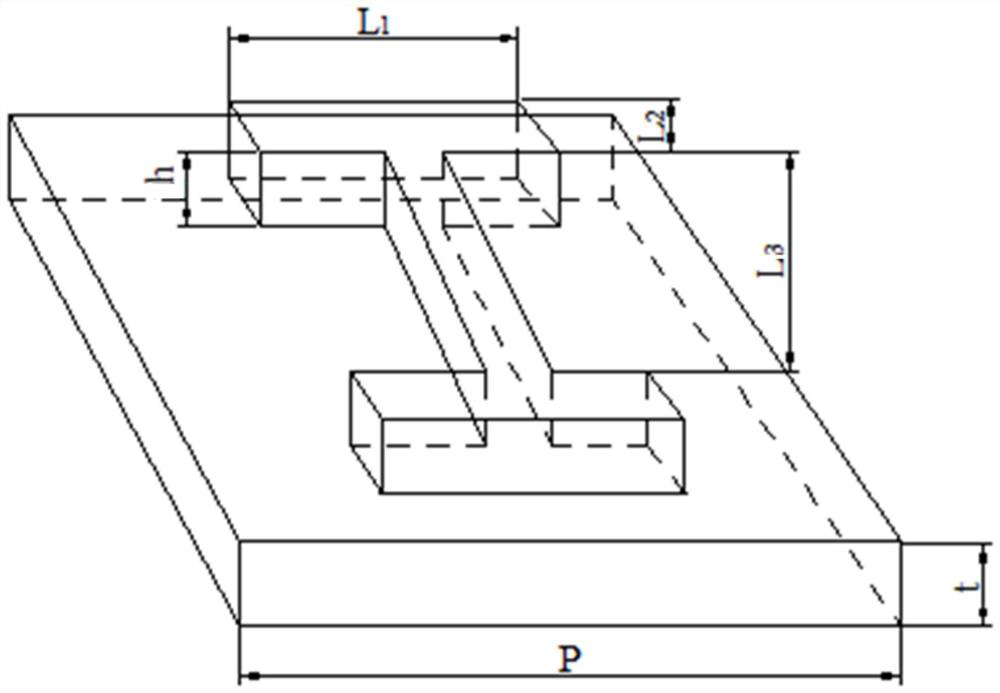

[0038] The microstructure can cover 0-2π phase modulation depth only by changing the structure size, and the microstructure can be designed for broadband phase modulation; then it can be applied to colli...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, if Figure 7 to Figure 8 As shown, the microstructure arrays are arranged on both sides of the substrate according to the position of a specific phase modulation depth, and the positions of the microstructure arrays on both sides are staggered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com