Water-cooled outer rotor motor

An external rotor motor and water cooling technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of dependence and reduce the working temperature of the motor, and achieve the effect of reducing the working temperature, increasing the working time and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

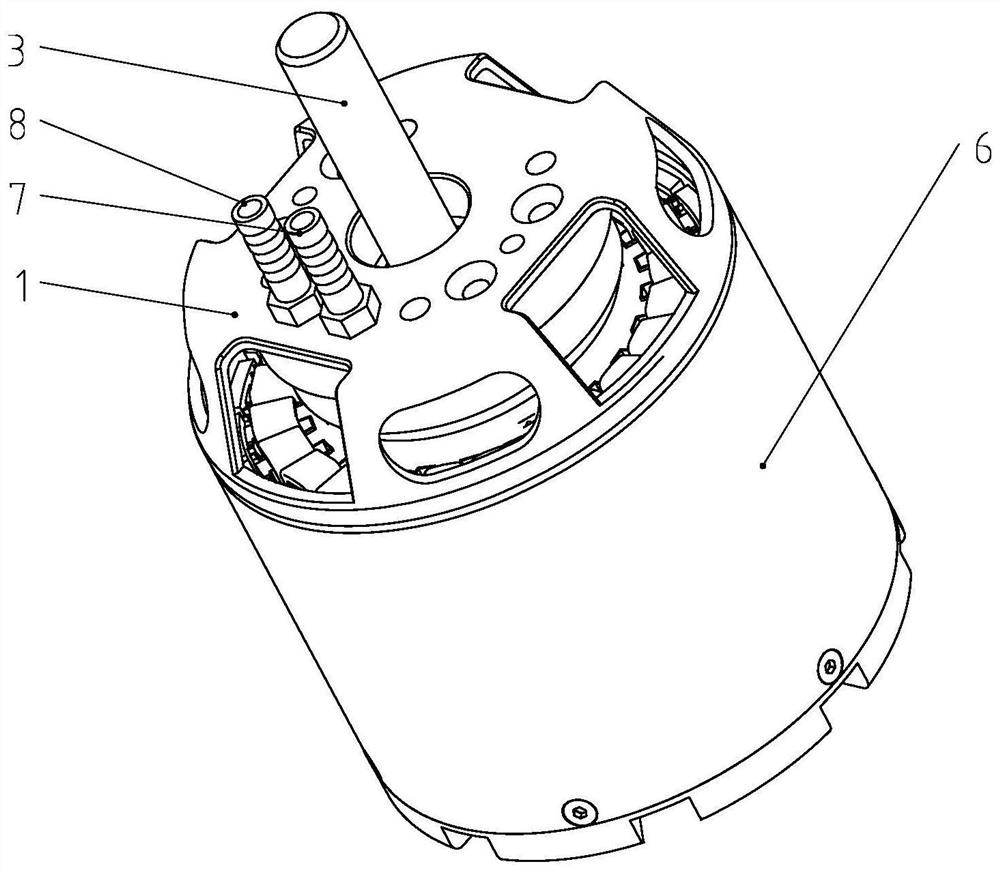

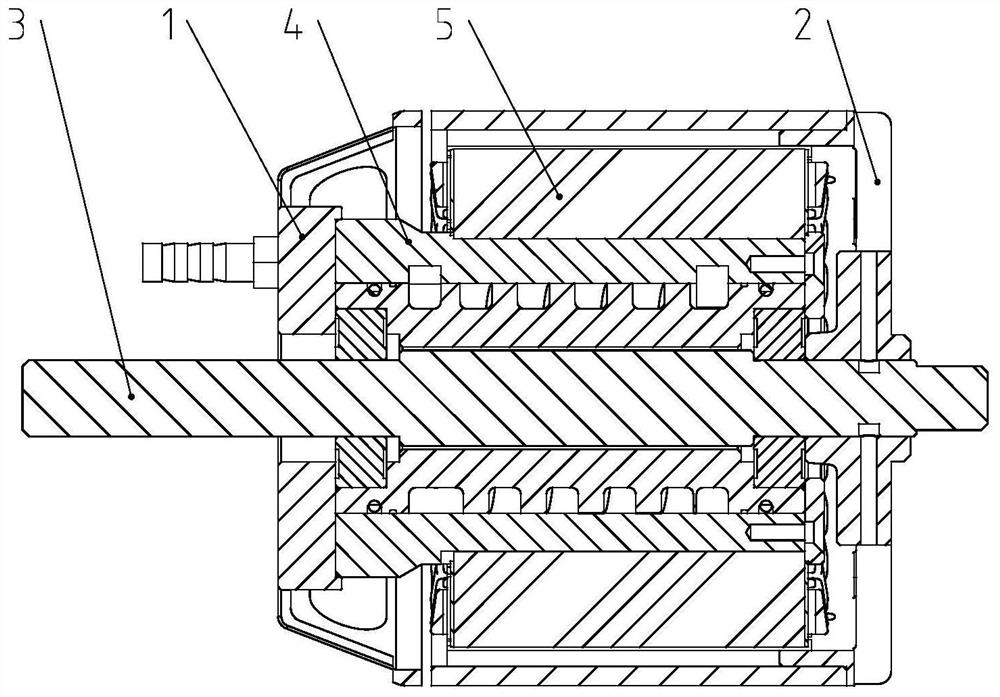

[0034] Such as figure 1 and figure 2 A water-cooled external rotor motor shown includes a front end cover 1, a rear end cover 2, a central shaft 3, a stator sleeve 4, a stator 5 and a rotor 6, the stator sleeve is set outside the central shaft, and the stator sleeve is set on the stator Outside the shaft sleeve, the rotor is sleeved outside the stator.

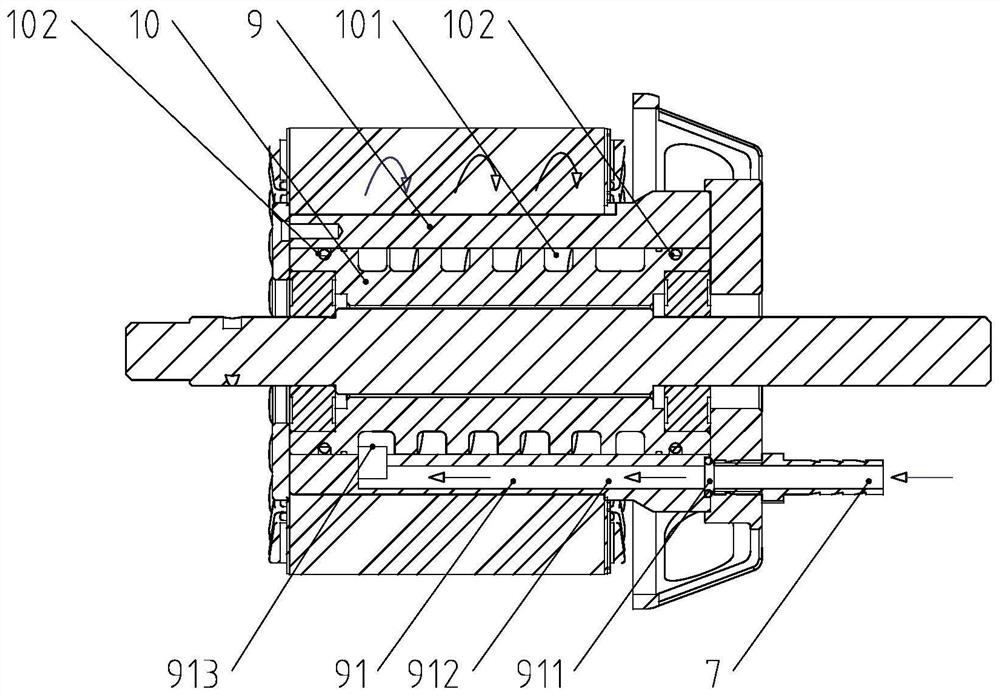

[0035] The front cover is provided with a water inlet nozzle 7 and a water outlet nozzle 8, such as image 3 and Figure 4 As shown, the stator bushing includes a stator bushing shell 9 and a stator bushing inner core 10, the stator bushing shell is set outside the inner core of the stator bushing, the stator bushing shell is provided with a water inlet part 91 and a water outlet part 92, and the stator bushing There is a spiral groove 101 on the surface of the inner core of the shaft sleeve, and the two ends of the spiral groove are respectively connected to the water inlet part and the water outlet part. A seal 102 is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap