Glass rod polishing device

A technology of polishing device and glass rod, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., which can solve the problems of reduced cleanliness of the environment around the surface of machine tools, reduced polishing effect, frequent cleaning by operators, etc. , to achieve the effect of reducing the amount of cleaning, beautiful appearance and smooth liquid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

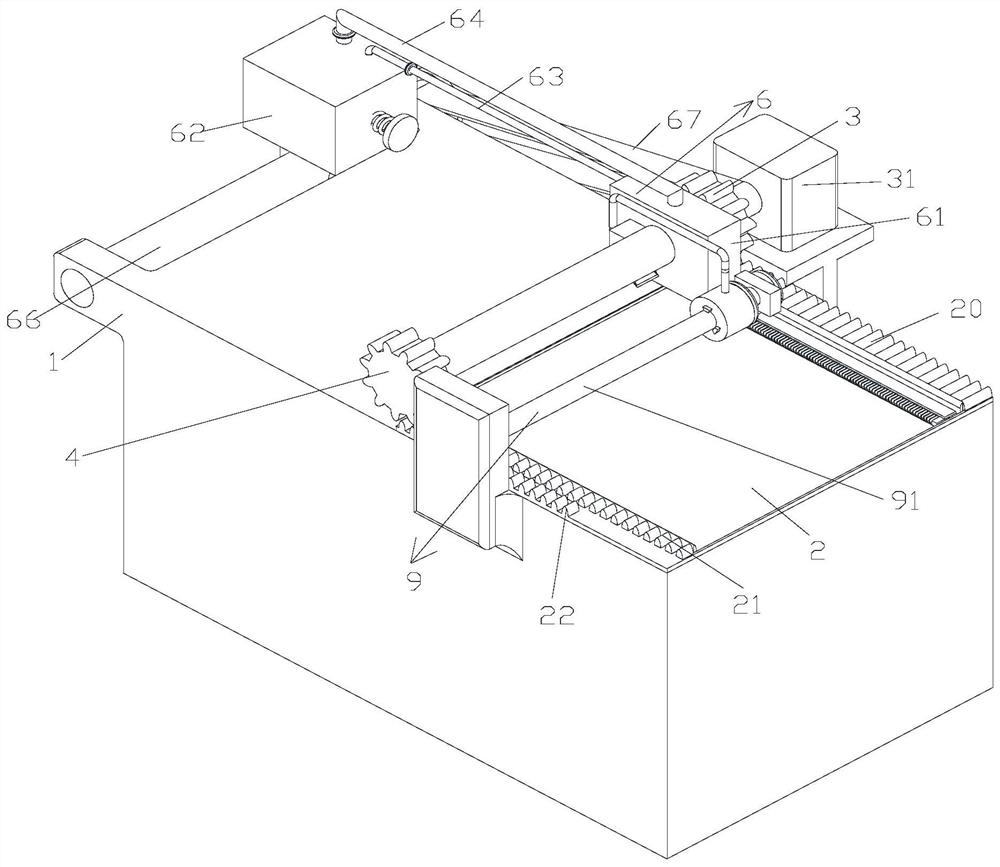

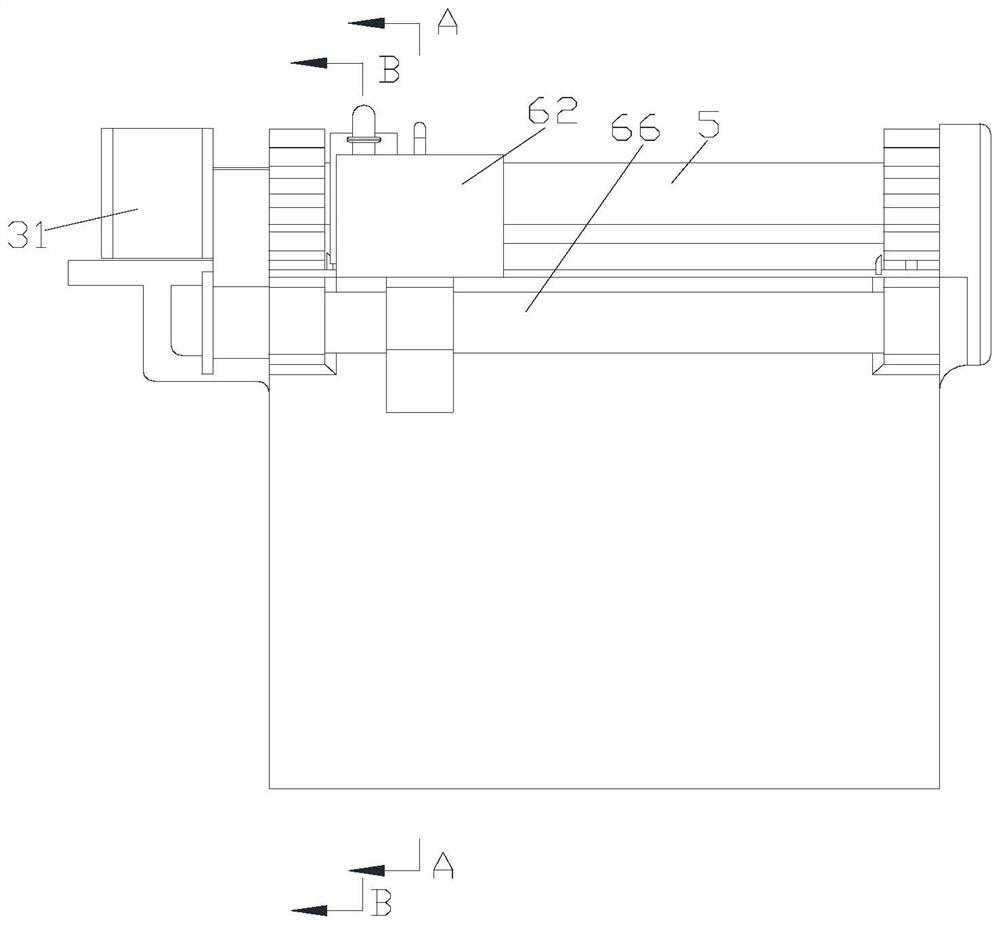

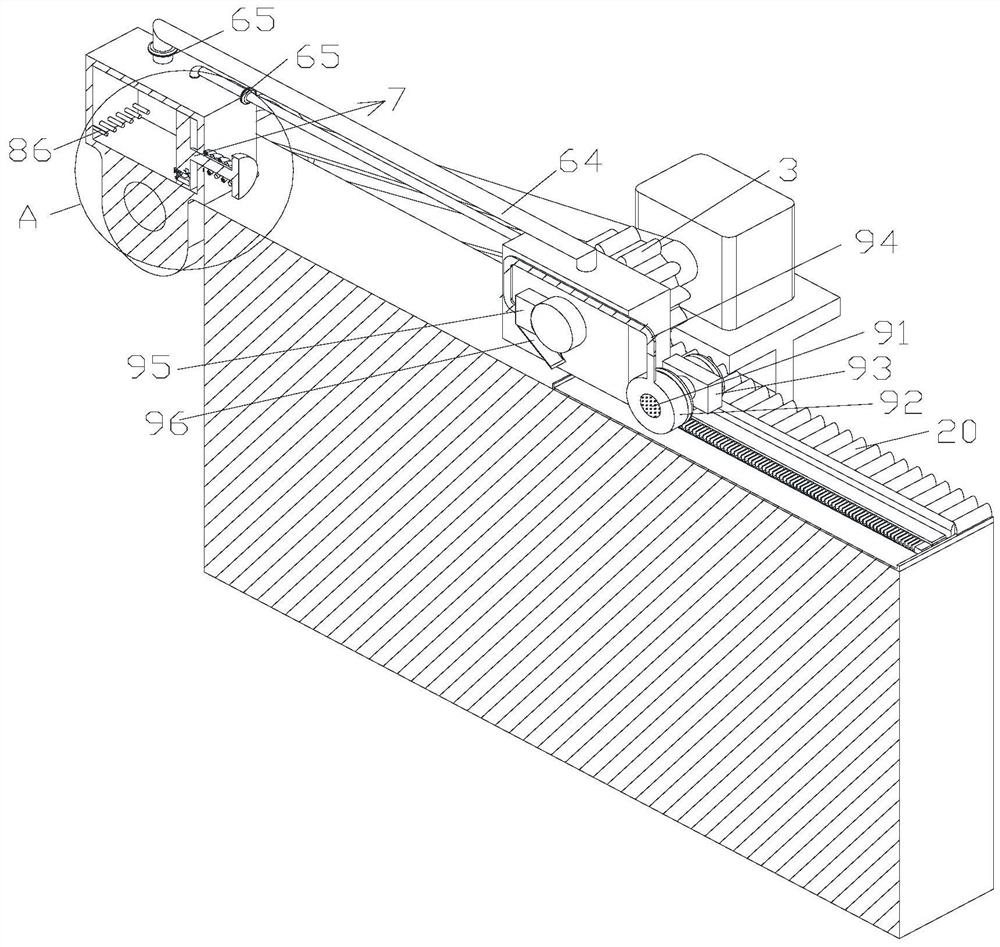

[0035] Such as Figure 1-14 As shown, a glass rod polishing device includes a base 1, a moving plate 2, a first large gear 3, a second large gear 4, a glass rod 5, and a first rotating shaft 30; the moving plate 2 is located on the base 1 and can move left and right along the lateral direction of the base 1; the first large gear 3 is arranged behind the central axis of the base 1, and the second large gear 4 is arranged in front of the central axis of the base 1; The glass rod 5 is arranged between the first large gear 3 and the second large gear 4, and the connection mode between the glass rod 5 and the first large gear 3 and the second large gear 4 is the prior art, and will not be repeated here; The first rotating shaft 30 is fixedly connected to the first large gear 3; the base 1 is provided with a motor 31 for the rotation of the first rotating shaft 30; the motor 31 is a prior art, and will not be repeated here.

[0036] The glass rod 5 is covered with a polishing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com