Aluminum profile electrophoresis cyclic utilization equipment and cyclic process thereof

An aluminum profile, electrophoresis technology, applied in the direction of electrophoresis plating, electrolytic paint, coating, etc., can solve the problems of poor electrophoresis effect, poor effect of electrophoresis recycling, and inability to adjust the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

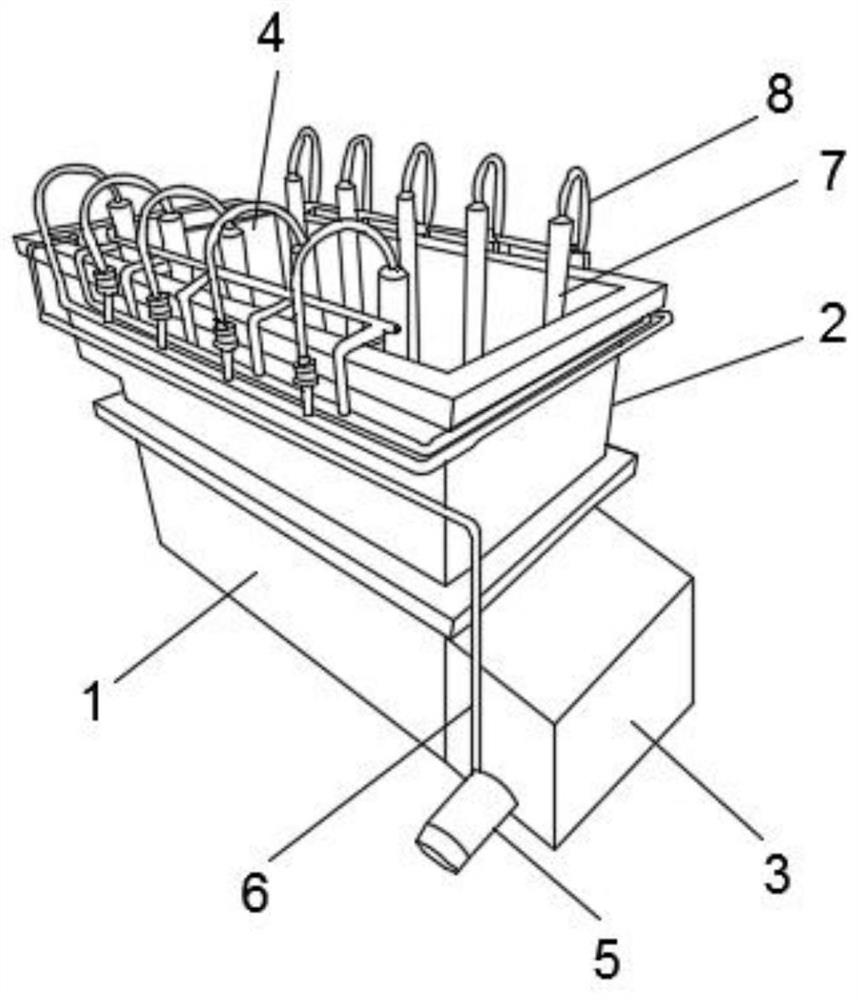

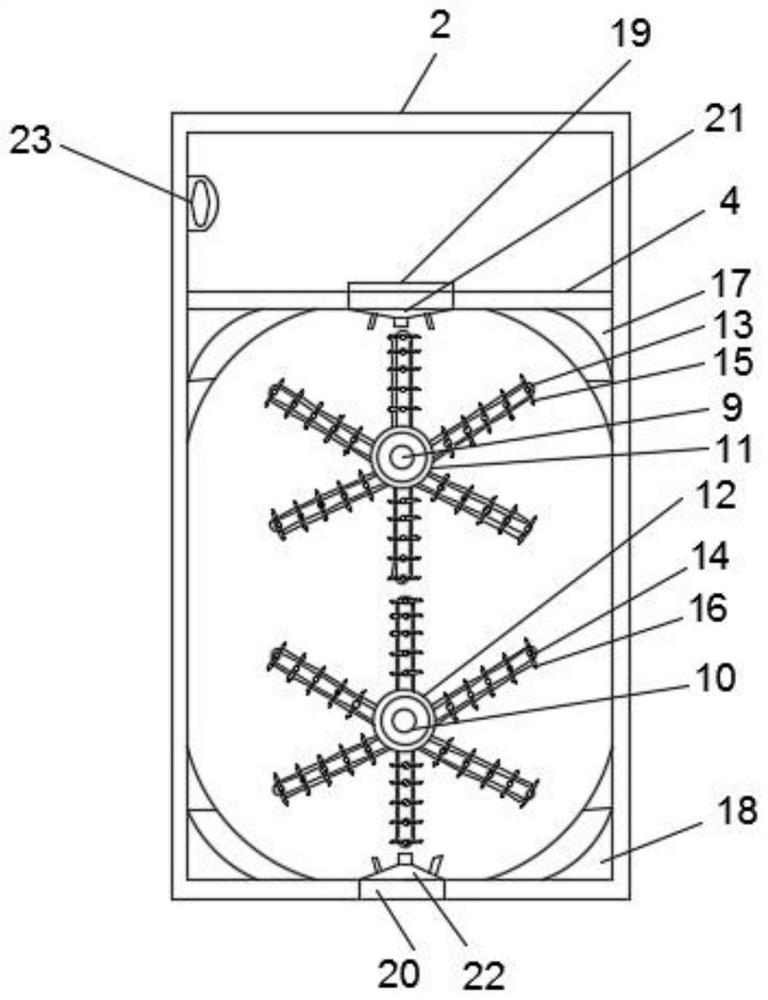

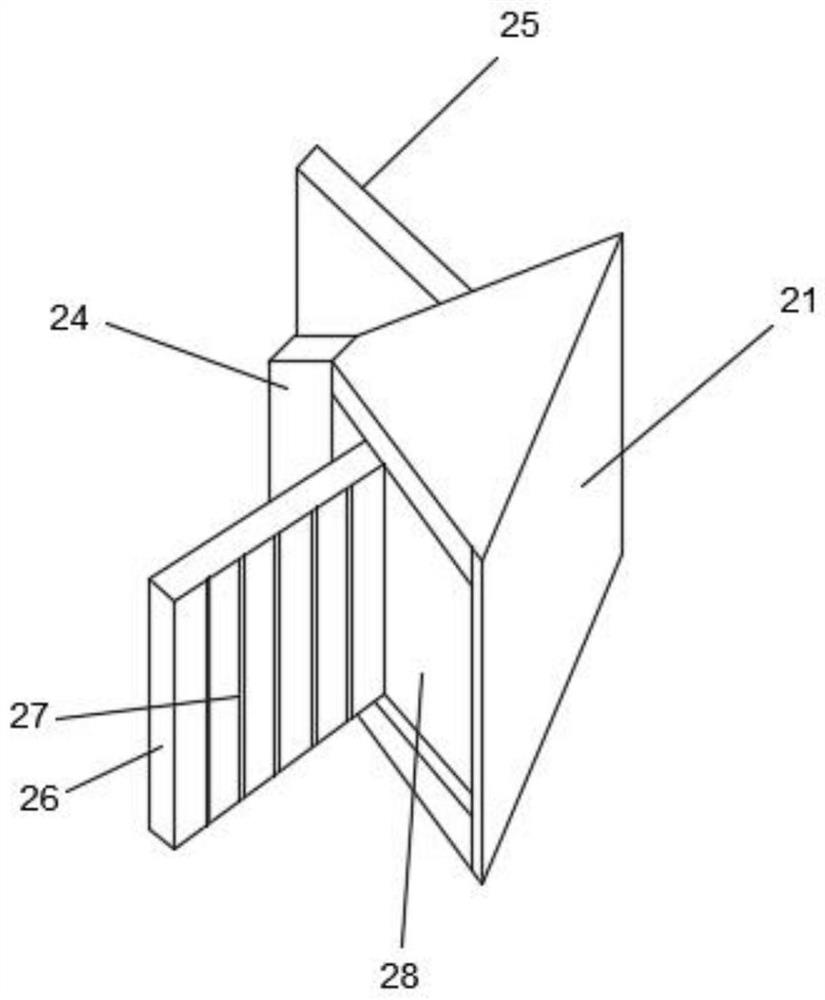

[0036] Such as Figure 1-7 As shown, an aluminum profile electrophoresis recycling equipment includes a support base 1, a processing base 2 and a filter box 3, the processing base 2 is fixedly installed on the upper end of the support base 1, and the filter box 3 is fixedly installed on the support base 1 One side of the processing seat 2 is fixed with an isolation plate 4 and several electrode tubes 7, the isolation plate 4 is located on one side of the plurality of electrode tubes 7, and the interior of the processing seat 2 is near the bottom The first rotating column 9 and the second rotating column 10 are connected in rotation, the first rotating column 9 is located on one side of the second rotating column 10, and the outer surface of the first rotating column 9 is fixedly equipped with a first connecting column 11 , the outer surface of the second rotating column 10 is fixedly installed with a second connecting column 12, the outer surface of the first connecting column...

Embodiment 2

[0046] A recycling process of electrophoretic recycling equipment for aluminum profiles, the recycling process includes the following steps:

[0047] Step 1: Transport the material to the second processing cavity in the processing seat 2, place the bottom end of the aluminum profile to be processed on the first limit seat 17 and the second limit seat 18, and place the upper end of the aluminum profile On the first baffle plate 25 and the second baffle plate 26 on the first adjustment seat 21 and the second adjustment seat 22, the first baffle plate 25 and the second baffle plate 26 are pulled outward, so that the clamping plate 29 and the clamping column Separate, move the first baffle plate 25 and the second baffle plate 26 on the first adjustment seat 21 and the second adjustment seat 22, so that the top of the aluminum profile is submerged by the material, adjust the first baffle plate 25 and the second baffle plate 26, push the first baffle plate 25 and the second baffle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com