Return air heat recovery and dust online cleaning evaporator module and heat pump drying device

An evaporator module and heat recovery technology, applied in the direction of cleaning heat transfer devices, evaporator/condenser, drying, etc., can solve the problems of huge initial investment, increased energy consumption of dust removal devices, etc., to overcome pollution and reduce heating power Large, high energy efficiency ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

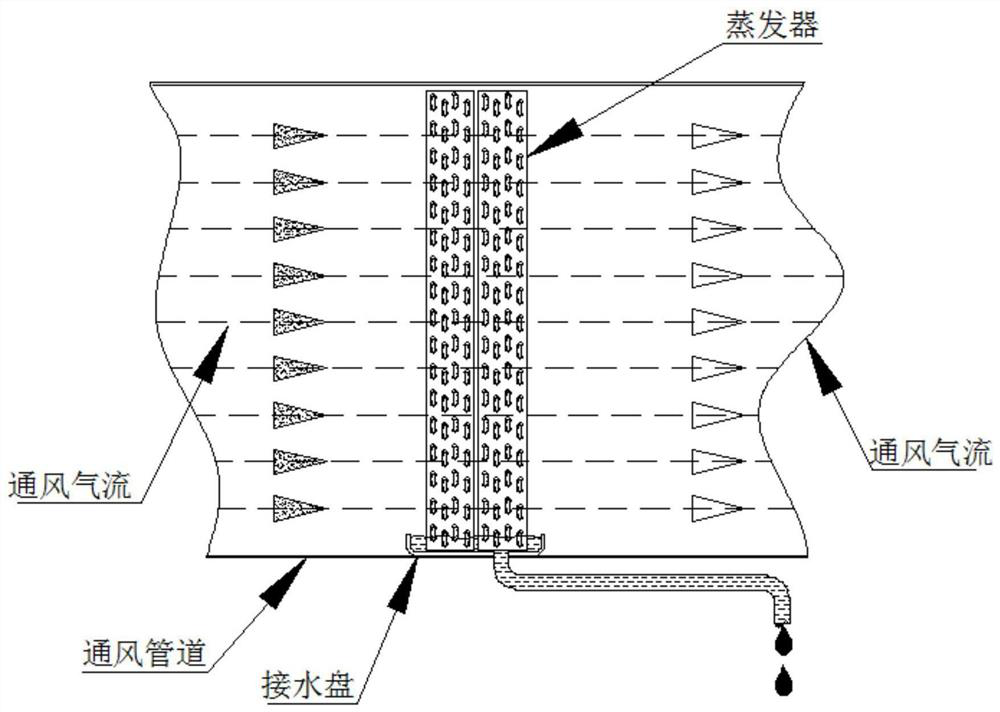

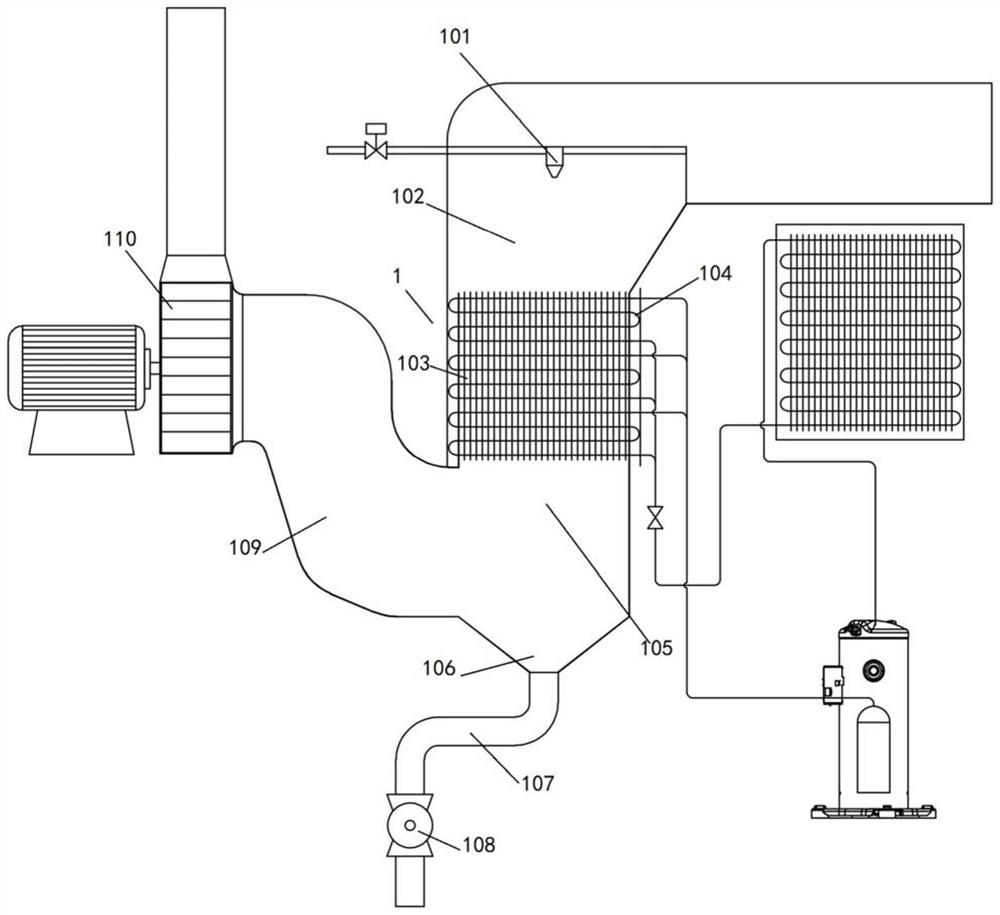

[0049] Please refer to Figure 3 to Figure 5 , an evaporator module 1 for return air heat recovery and online dust cleaning, the air duct of the evaporator module 1 is changed from the traditional horizontal setting to the vertical setting, and the water connection of the jacking evaporator in the traditional evaporator module is cancelled. The tray, that is, the bottom of the evaporator module 1 is a non-contact water receiving tray with a downward open air path structure, so that the warm and humid return air from the drying device can flow through the evaporator smoothly from top to bottom. Specifically, the evaporator module 1 includes at least one evaporator 104, the air duct of the evaporator module 1 is a vertical air duct, and the warm and humid return air from the drying device passes through the vertical air duct from above to Flow down through the evaporator 104; the vertical air channel includes a water mist mixing section 102, an endothermic adsorption section 103...

Embodiment 2

[0068] This embodiment is further improved on the basis of Embodiment 1.

[0069] In this embodiment, the lower end of the sewage tank 106 communicates with the sewage pool through a sewage pipe. During operation, since the return air in the air-pollution separation section 105 is drawn out by the centrifugal fan 110, the air-pollution separation section 105 generates negative pressure, which is not conducive to discharging the mud into the sewage tank. Therefore, need to do further improvement to blowdown pipe.

[0070] As an example, please refer to Figure 3 to Figure 5 , the outlet of the sewage discharge pipe 107 is vertically downward, and the sewage discharge pipe 107 is provided with valves, such as electric valves, ball valves 108 and the like.

[0071] As another example, please refer to Figure 6 , the sewage discharge pipe 107' is a U-shaped pipe. The sewage discharge outlet of this U-shaped pipe is different from the above-mentioned embodiment. Its sewage disch...

Embodiment 3

[0073] This embodiment provides a heat pump drying device, including a heat pump unit, and the heat pump unit includes the return air heat recovery and dust online cleaning evaporator module 1 described in any of the above embodiments. In this embodiment, there is no specific limitation on which field the heat pump drying device is applied to.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com