Multi-target flexible job shop scheduling method

A workshop scheduling and flexible operation technology, applied in the field of workshop scheduling, can solve problems such as single flexible job workshop scheduling, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

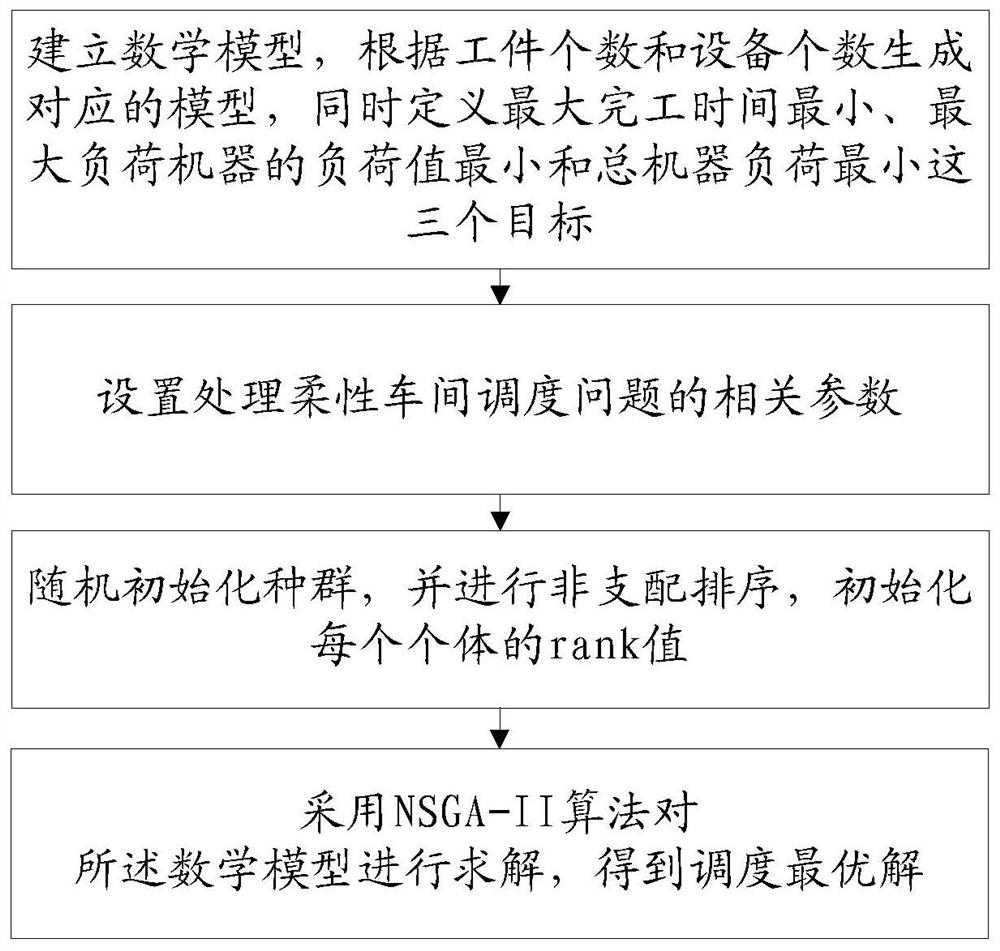

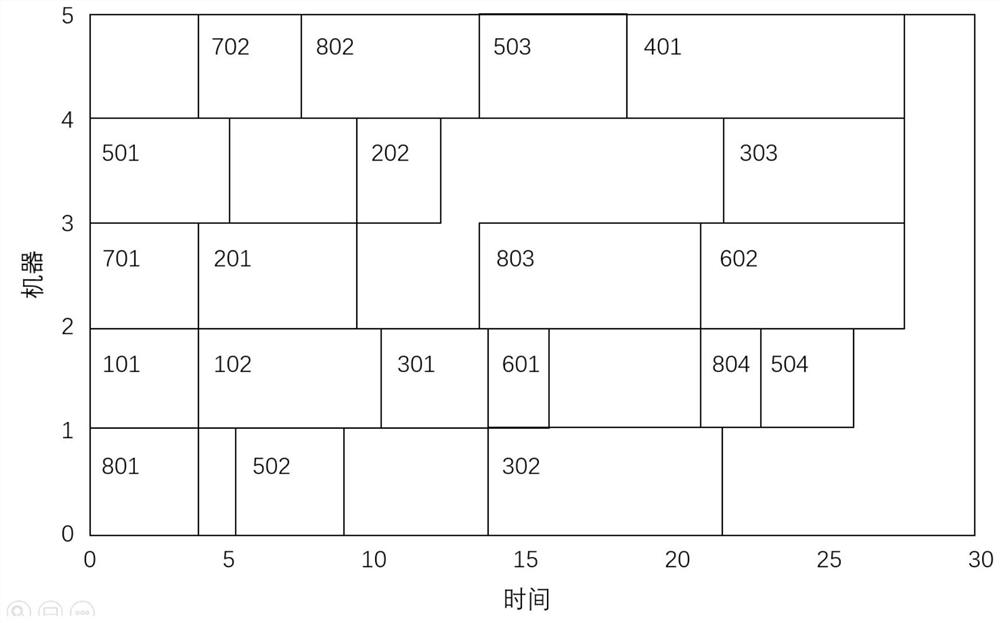

[0043] Such as Figure 1 to Figure 4 As shown, a kind of multi-objective flexible job shop scheduling method of the present invention comprises:

[0044] Step S10, establish a mathematical model, generate a corresponding model according to the number of workpieces and the number of equipment, and define three objectives: the minimum maximum completion time, the minimum load value of the maximum load machine, and the minimum total machine load;

[0045] Step S20, setting relevant parameters for processing the flexible workshop scheduling problem;

[0046] Step S30, randomly initialize the population, perform non-dominated sorting, and initialize the rank value of each individual;

[0047] Step S40, using the NSGA-II algorithm to solve the mathematical model to obtain an optimal scheduling solution.

[0048] Preferably, said step 10 further includes:

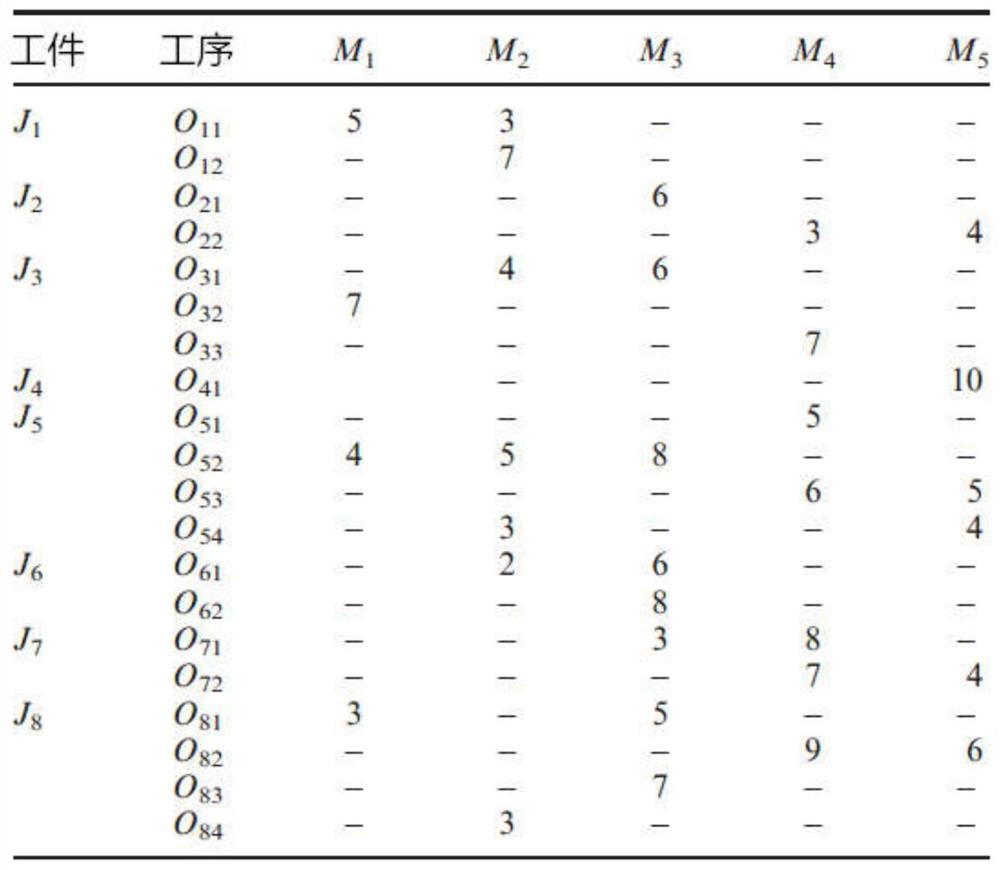

[0049] Step 11, establish a mathematical model, the mathematical model includes 4 concepts: workpiece, operation, equipment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com