Metal additive forming part surface heat transfer coefficient simulation method based on heat flow coupling

A metal additive, heat transfer coefficient technology, applied in complex mathematical operations, electrical digital data processing, CAD numerical modeling, etc., can solve problems such as errors, achieve accurate numerical simulation results and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for simulating the surface heat transfer coefficient of a metal additive formed part based on heat flow coupling provided in this embodiment includes the following steps:

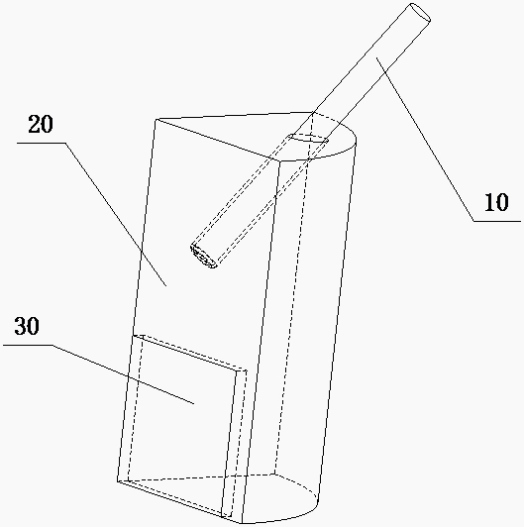

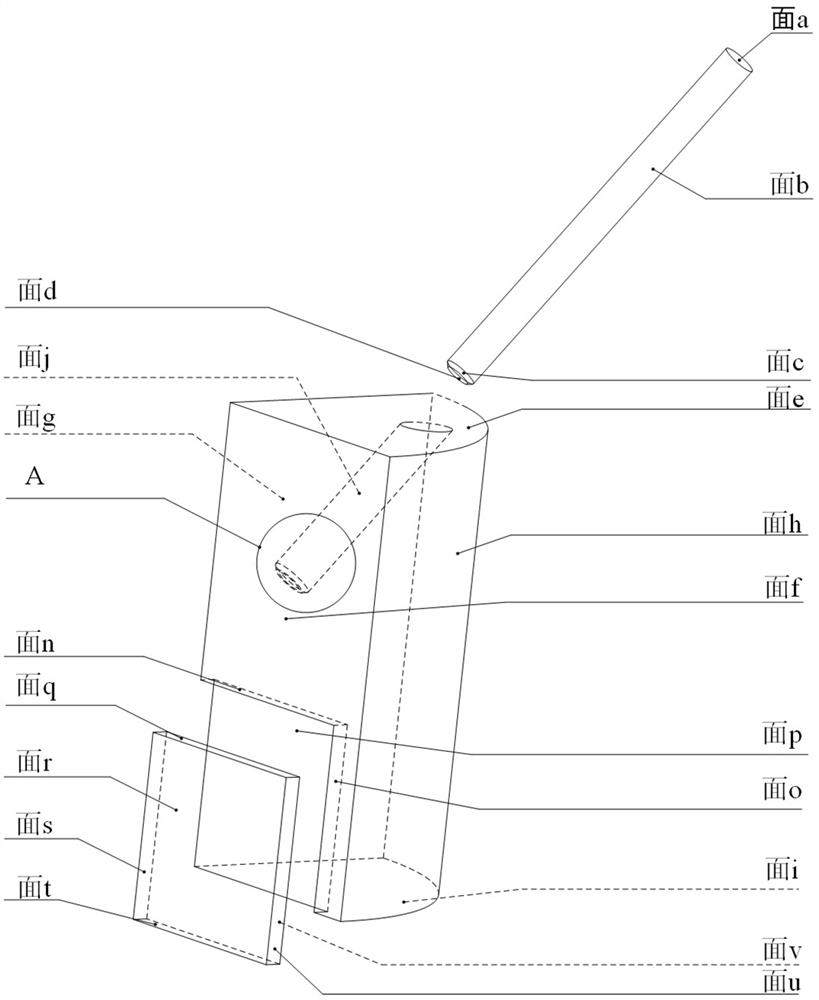

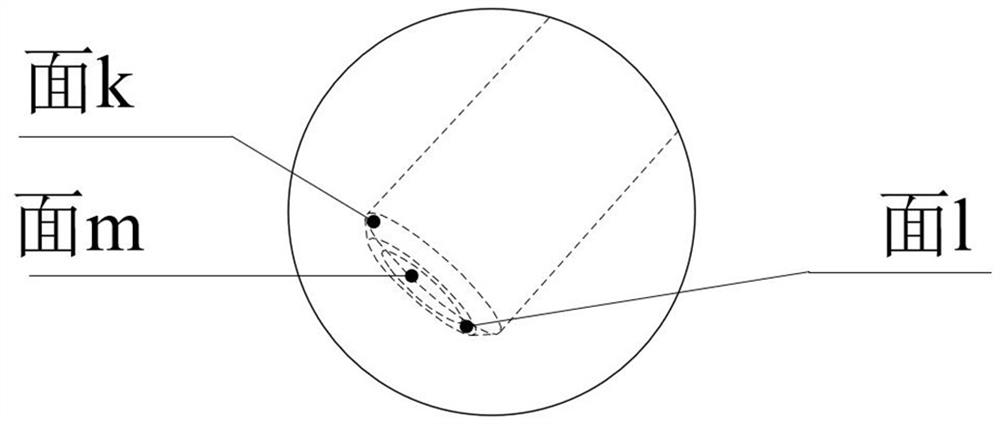

[0038] (1) Use 3D drawing software to compile the geometric model of the printed part and the flow field around the printed part, and perform finite element analysis on the geometric model, which includes the geometric model of the flow field inside the nozzle 10, the geometric model of the flow field outside the nozzle Model 20 and printed part geometric model 30; present embodiment adopts SolidWorks software to draw respectively the flow field geometric model 10 in the nozzle, the flow field geometric model 20 outside the nozzle and the printed part geometric model 30, and the geometric model drawn is assembled, Such as figure 1 As shown, the geometric model 10 of the flow field inside the nozzle, the geometric model 20 of the flow field outside the nozzle and the geometric model 30 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com