Movable additive and subtractive composite manufacturing system

A manufacturing system and a technology of adding and subtracting materials, which is applied in the field of mobile adding and subtracting materials composite manufacturing systems, can solve problems such as unguaranteed machining accuracy, inability to move operations, and inability to automatically level, etc., to achieve convenient compound manufacturing of adding and subtracting materials and improve Portability and the effect of improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

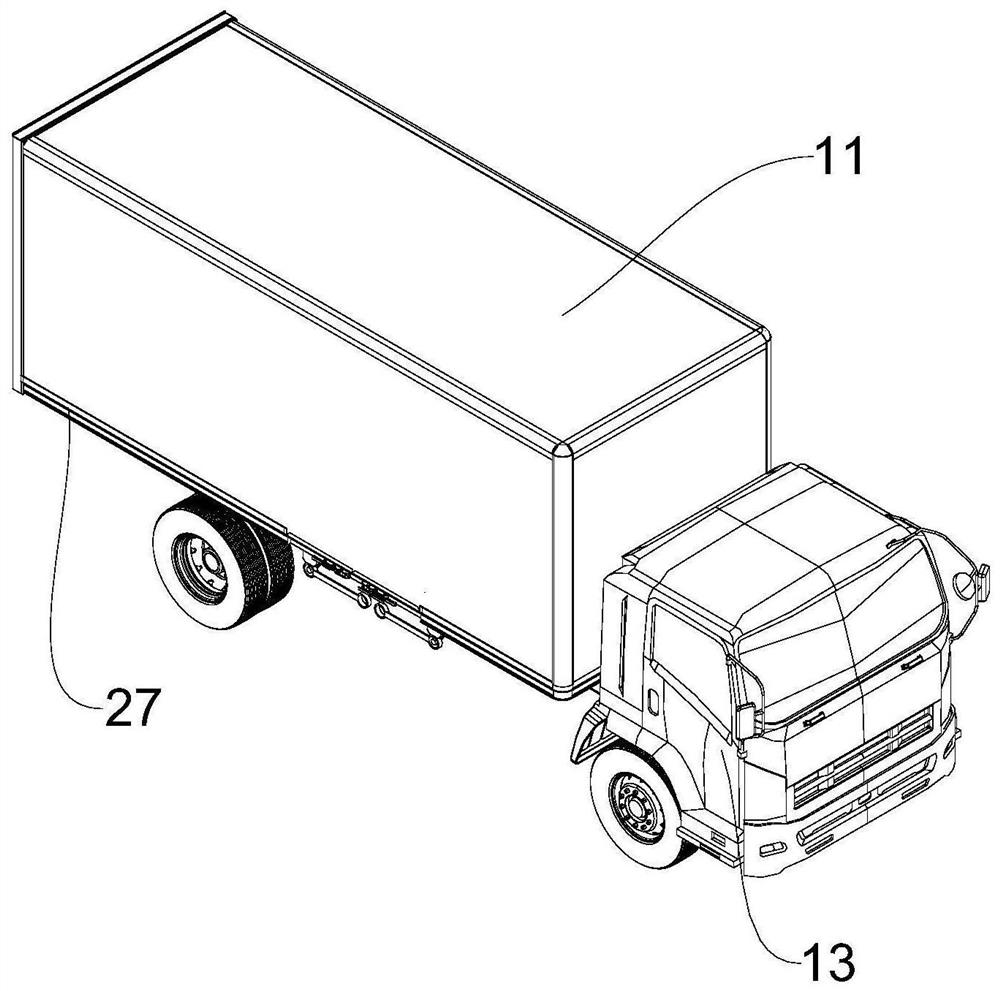

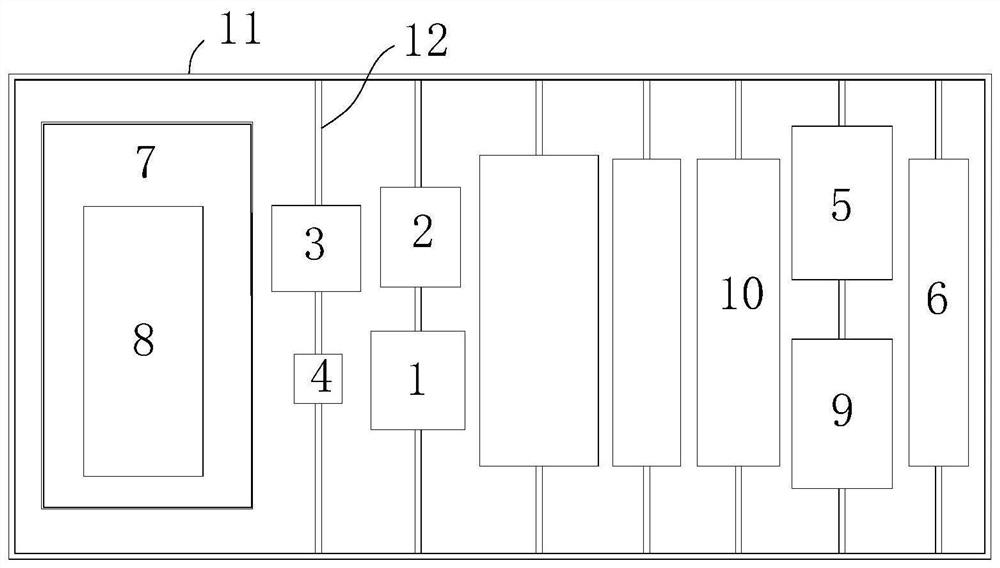

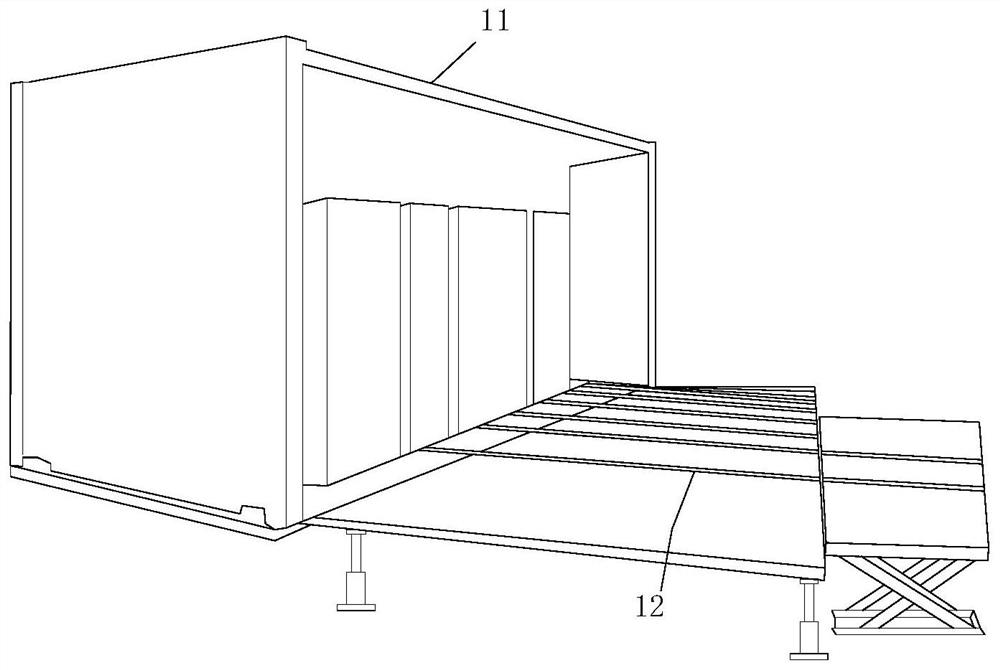

[0050] Please refer to Figure 1-Figure 7 shown. This embodiment provides a mobile additive and subtractive material composite manufacturing system, including a transport vehicle 13, a shelter main body 11, a platform device 27, and an additive and subtractive material composite manufacturing equipment; the platform device 27 passes between the transport vehicle 13 and the shelter main body 11 connection, the cabin main body 11 is equipped with additive and subtractive composite manufacturing equipment.

[0051] In the above embodiment, a mobile additive and subtractive material composite manufacturing system is composed of a transport vehicle 13, a shelter main body 11, a platform device 27 and an additive and subtractive composite manufacturing equipment; wherein, the shelter body can be assembled on the shelter transport vehicle 13 On the other hand, open and stop at any time, which greatly improves the portability of additive and subtractive material manufacturing. When p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com