Manufacturing process of transparent cloisonne enamel type herbarium artware

A plant specimen and production process technology, applied in decorative arts, special decorative structures, decorative structures, etc., can solve the problems of lack of three-dimensional fidelity in natural state, inability to depict fine veins and lines, affecting the realism of finished patterns, etc., to improve production. Efficiency, rapid prototyping, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

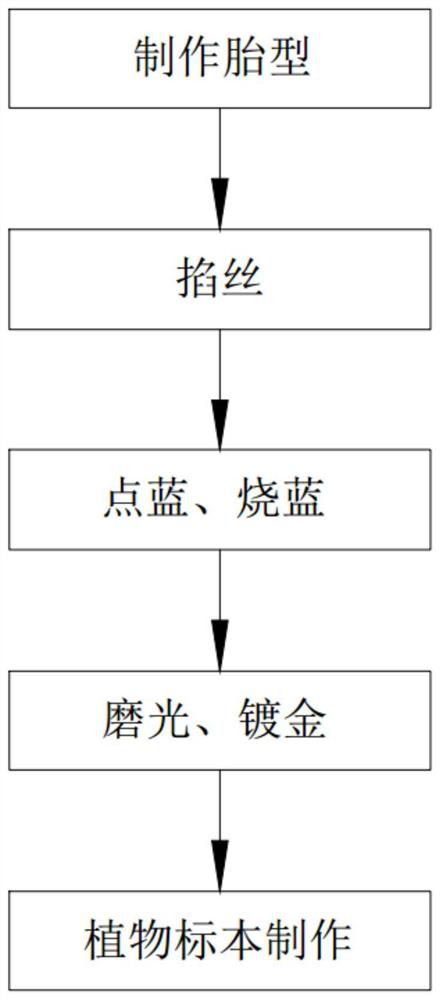

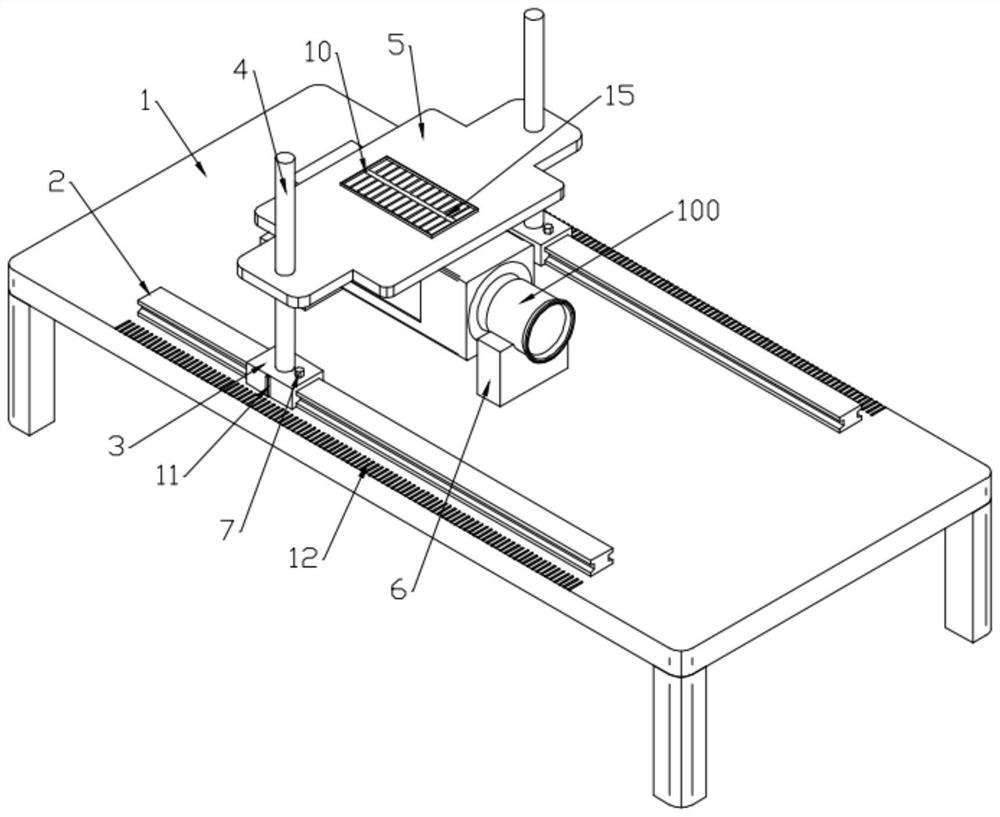

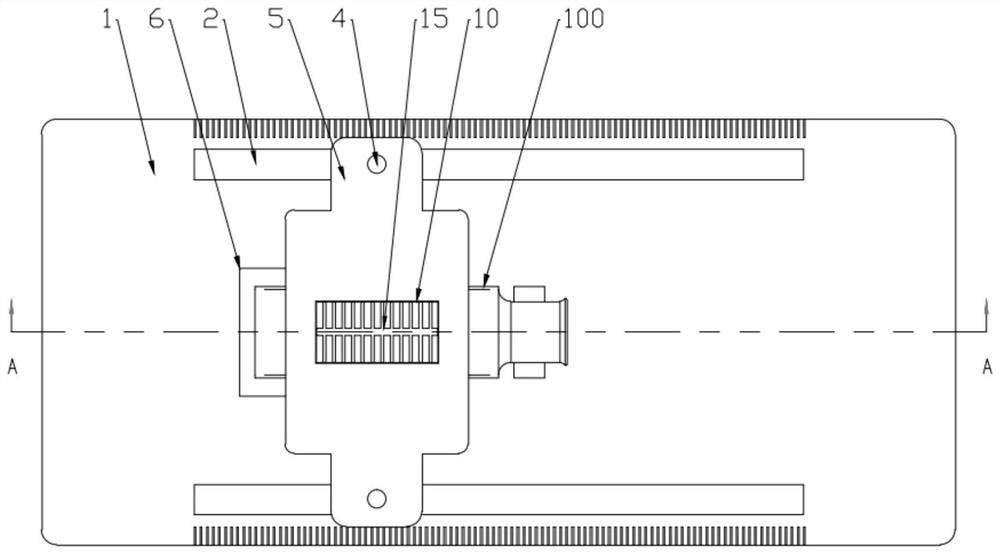

[0032] Such as Figure 1 to Figure 8 As shown, a transparent cloisonné enamel-style herbarium handicraft manufacturing process includes the following steps:

[0033] (1) Making the tire shape: Now cut the copper sheet into various shapes according to the design drawing requirements, and beat it into various shapes of copper tires with a hammer, and then connect the various parts with good welding powder, and weld them at high temperature Later, it became the shape of a copper vessel;

[0034] (2) Filigree: Use tweezers to pinch and break the flattened copper wire into various patterns, then dip bletilla striata on it to stick to the copper tire, then sieve silver solder powder, and bake at a high temperature of 890-910°C , firmly weld the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com