Active thermal control distributed electro-hydraulic servo steering engine

An electro-hydraulic servo, distributed technology, applied in the field of aircraft design, can solve problems such as reliability reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

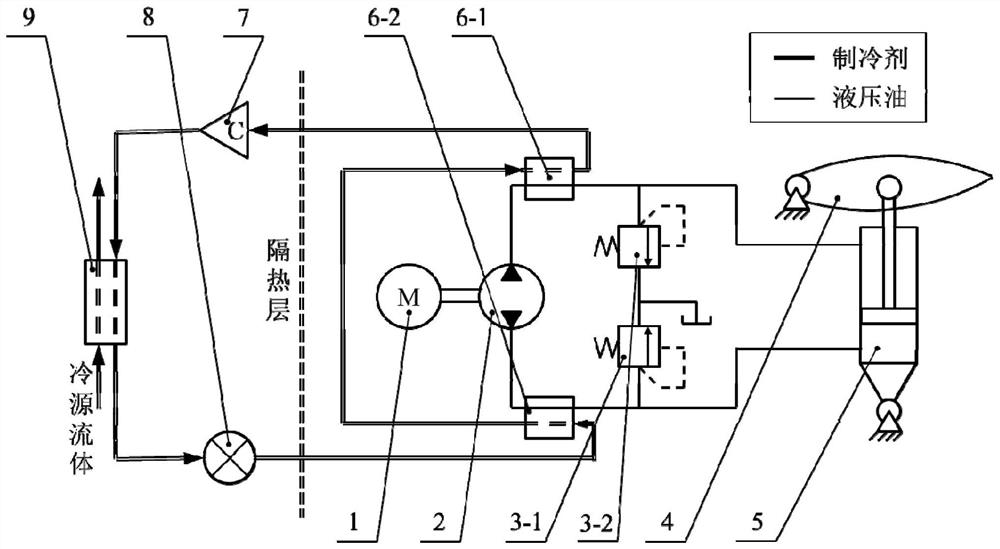

[0017] An active thermal control distributed electro-hydraulic servo steering gear, including a servo motor 1, a bidirectional hydraulic pump 2, an overflow valve, a rudder surface 4, an actuator 5, an evaporator, a compressor 7, an expansion valve 8 and a condenser device 9;

[0018] The double-rotation hydraulic pump 2 is driven by the servo motor 1, the output flow of the double-rotation hydraulic pump 2 is controlled by the rotating speed of the servo motor 1, the double-rotation hydraulic pump 2 controls the speed of the piston rod of the actuator cylinder 5, and the piston rod Connect the steering surface 4 to control the deflection rate of the steering surface 4; the compressor 7 is driven by the servo motor 1 to improve the integration of the whole system.

[0019] The output ports of the dual-rotational hydraulic pump 2 are respectively arranged with evaporator A6-1 and evaporator B6-2, and the low-pressure, gaseous refrigerant evaporates and absorbs heat when it circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com