Trailing edge flap-type smart rotor blade

A technology of trailing edge flaps and rotor blades, which is applied in the field of helicopter component design, can solve problems such as large gaps, unreasonable partial design, and no complete and effective solution for the integrated design of the drive system. Ease of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

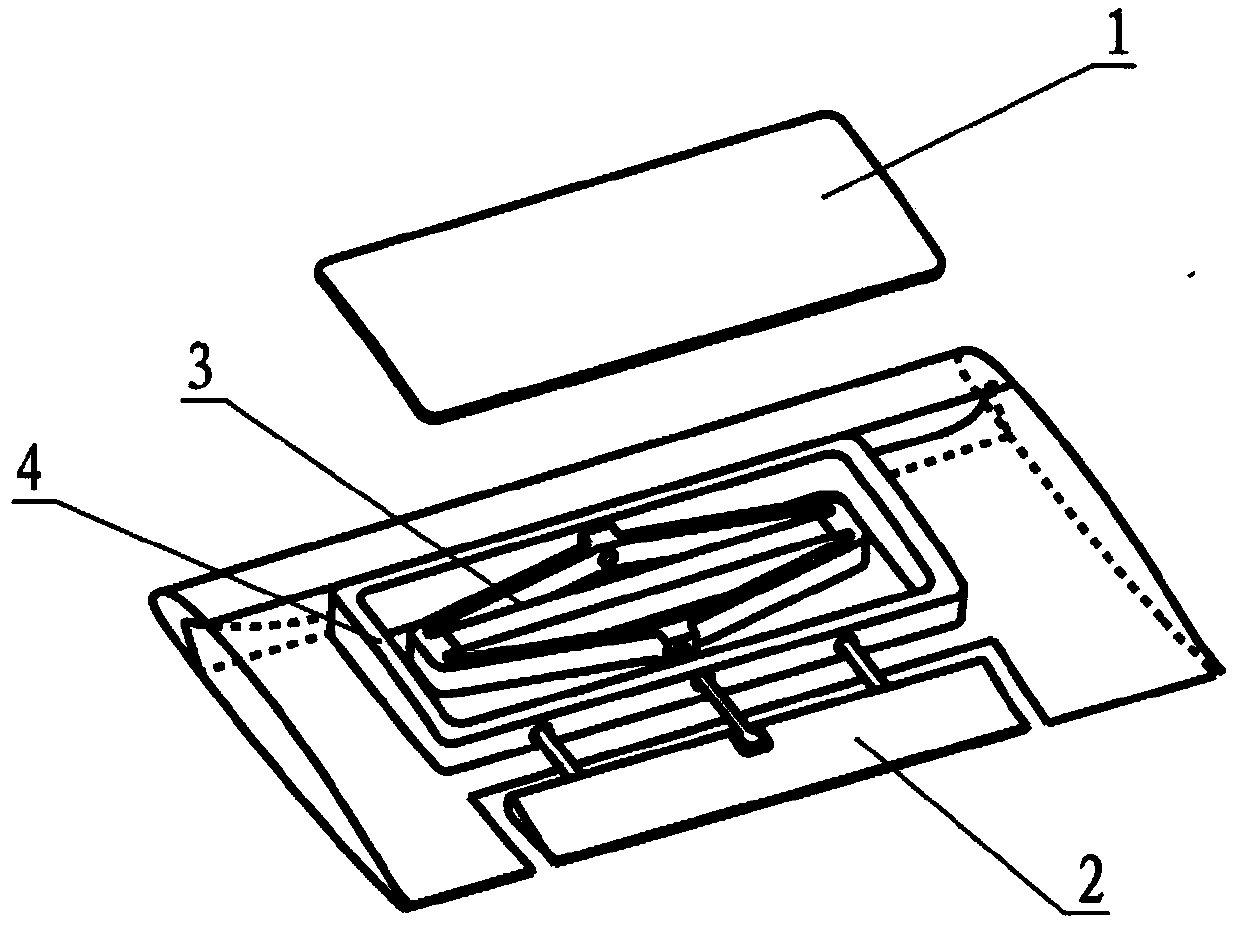

[0045] A trailing edge flap type intelligent rotor blade is characterized in that:

[0046] (1) The trailing edge flap type intelligent rotor blade includes the blade body, drive frame, actuator, and trailing edge flap, and each part is connected by binding, bonding, and bolt fastening;

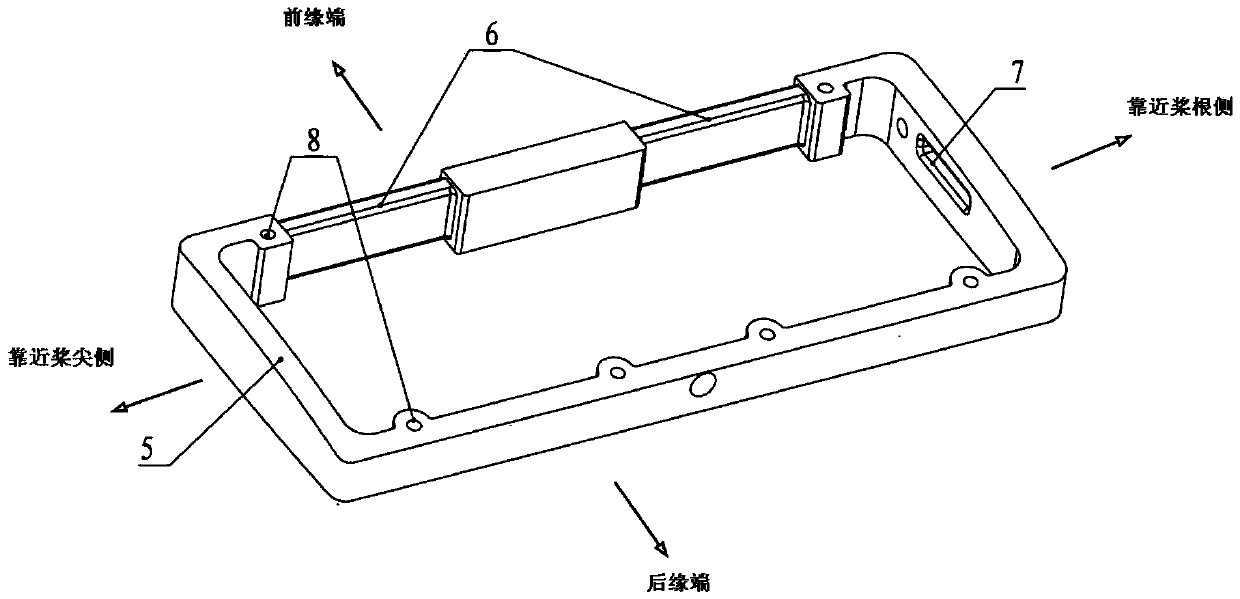

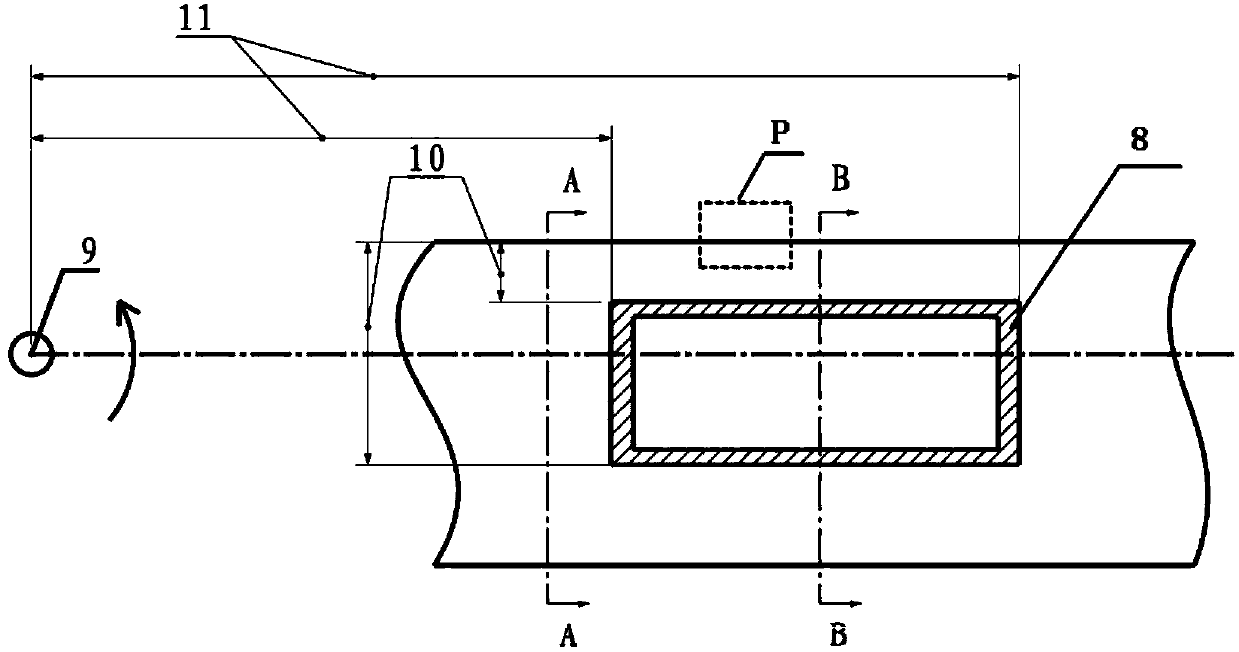

[0047] (2) The drive frame is included in the blade skin, its upper and lower surfaces are parallel to the upper and lower airfoil surfaces, and the leading edge end face is pasted on the end face of the blade beam; grooves are made at both ends of the leading edge wall of the drive frame, and the beam belt is used to fit the groove Wrap the front edge wall of the drive frame on the leading edge beam of the blade; open a hole on the side wall of the drive frame close to the root of the blade, and wrap the middle beam of the blade through the hole and wrap it on the inner bolt; the drive frame is close to the tip of the blade. Blocking blocks made of glass fiber fabric cloth and carbon fiber f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com