Efficient thin-film photovoltaic hollow glass and production method thereof

A thin-film photovoltaic and hollow technology, applied in the direction of photovoltaic modules, photovoltaic power generation, photovoltaic module support structures, etc., can solve the problems of waste in enterprises, difficult to fix photovoltaic panels, etc., to protect pedestrians, facilitate maintenance and replacement, and reduce electricity consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

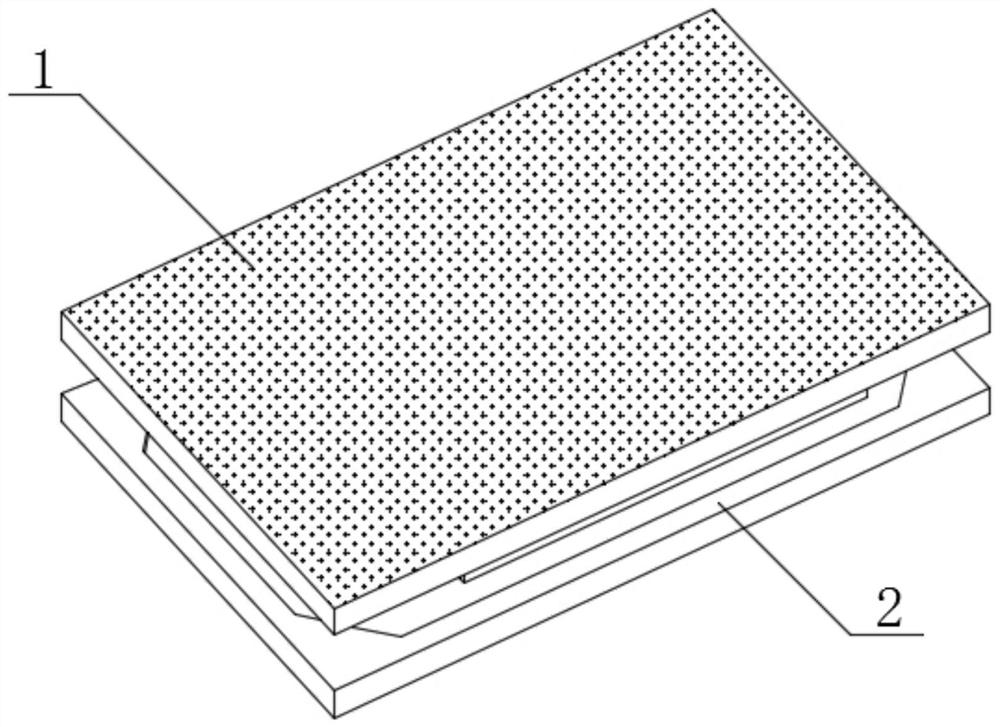

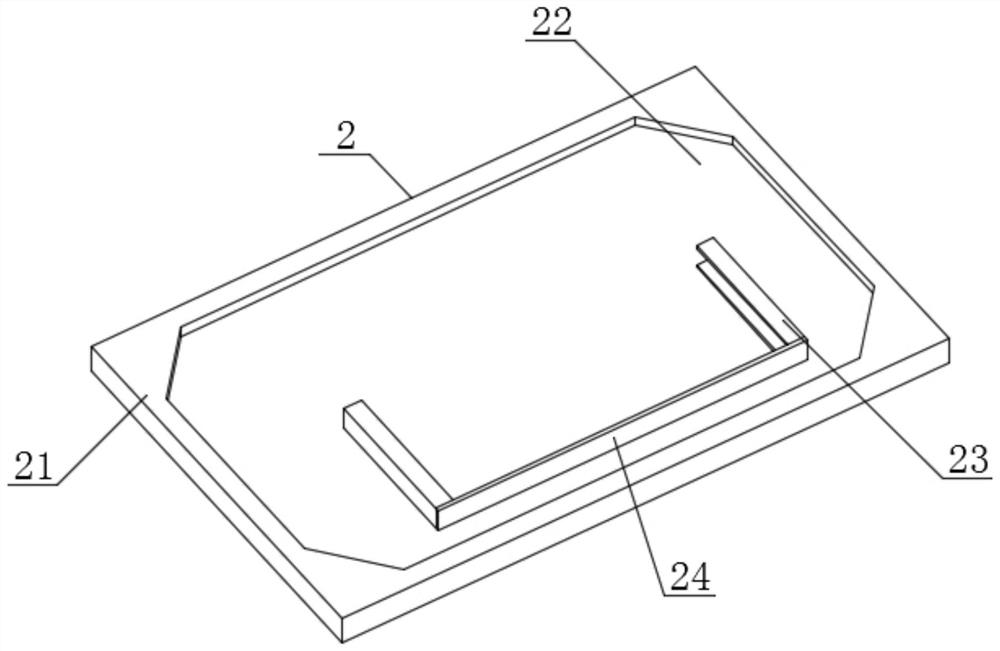

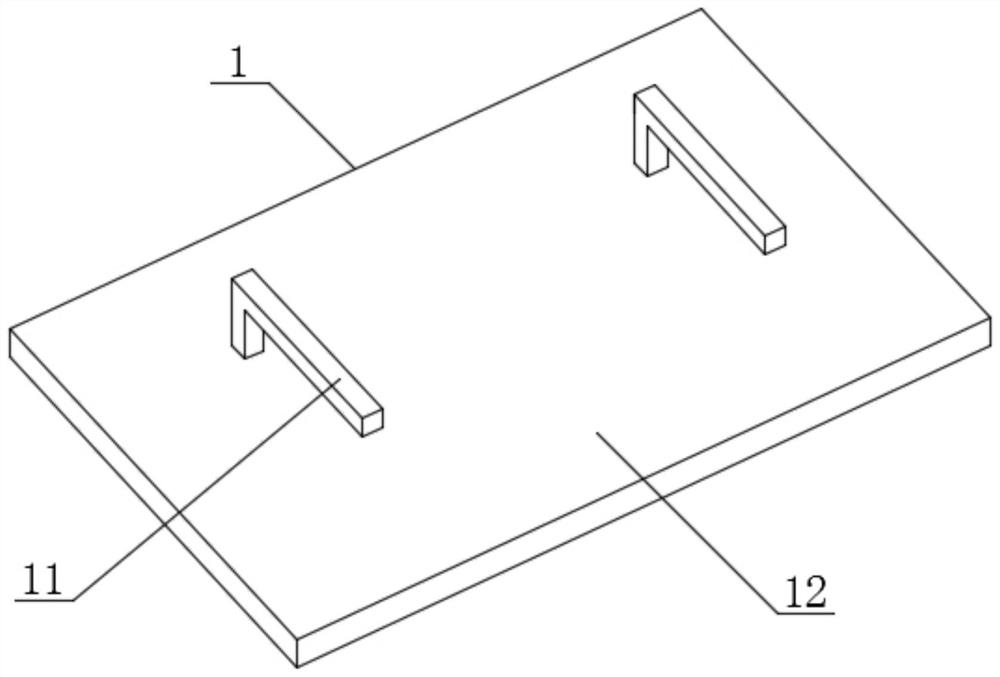

[0024] Such as Figure 1-3 As shown, a high-efficiency thin-film photovoltaic insulating glass includes a photovoltaic panel 1. The lower end of the photovoltaic panel 1 is clamped with an insulating glass 2. The upper end of the insulating glass 2 is provided with a clamp. The insulating glass 2 includes an outer frame 21. The inner frame 21 A glass plate 22 is fixed on the surface, and the fixture includes two slots 23 placed horizontally. The lower end of the slot 23 is fixed with a bottom plate 24. The photovoltaic panel 1 includes a board body 12, and the upper end of the board body 12 is fixed with a clamp rod 11. The outer surface profile is the same as the inner surface profile of the slot 23 .

[0025] Fix the insulating glass 2 on the surface of the glass curtain wall, move the card slot 23 so that the card slot 23 is aligned with the glass plate 22, fix the card slot 23 on the surface of the glass plate 22 with glue, and move the bottom plate 24 to align the bottom ...

Embodiment 2

[0027] Such as Figure 1-4 As shown, a high-efficiency thin-film photovoltaic insulating glass includes a photovoltaic panel 1. The lower end of the photovoltaic panel 1 is clamped with an insulating glass 2. The upper end of the insulating glass 2 is provided with a clamp. The insulating glass 2 includes an outer frame 21. The inner frame 21 A glass plate 22 is fixed on the surface. The glass plate 22 includes an upper plate surface 221 and a lower plate surface 222 . The upper end of the upper plate surface 221 is glued to the lower plate surface 222 .

[0028] The upper plate surface 221 and the lower plate surface 222 are 6mm glass, which are aligned with each other and connected by glue. Compared with the structure of the existing insulating glass 2 (6-12-6), the strength of the glass plate 22 can be effectively increased. 22 When broken, because the two layers of glass slag will not splash around because of the mutual adhesion of the two layers, it can effectively protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com