A device for cooking and pulverizing fish material

A pulverizing device and fish feed technology, applied in the directions of transportation and packaging, application, grain processing, etc., can solve the problems of limited stirring range of the stirring rod, inability to move the fish feed as a whole, uneven heating of the fish feed, etc., to improve the cooking effect, The effect of increasing pressure and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

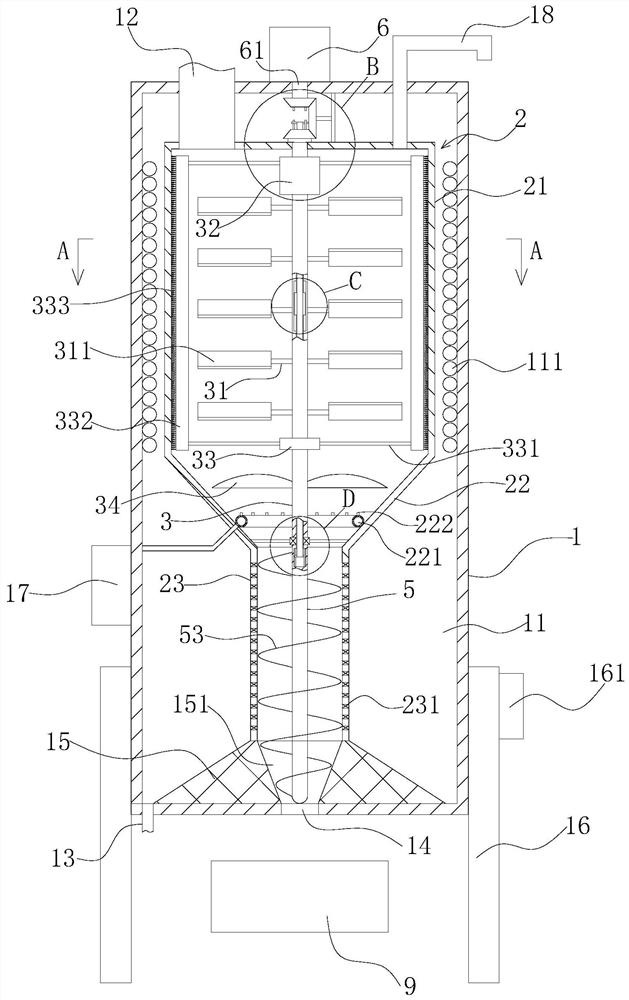

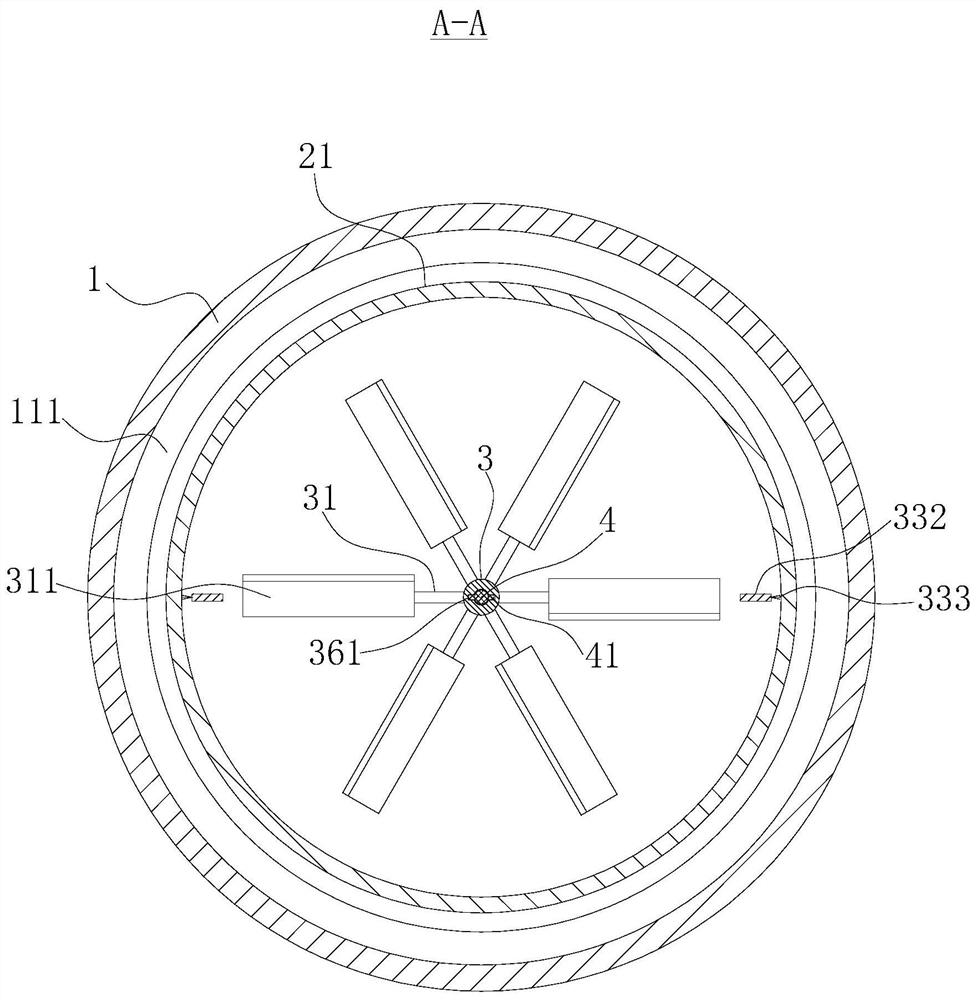

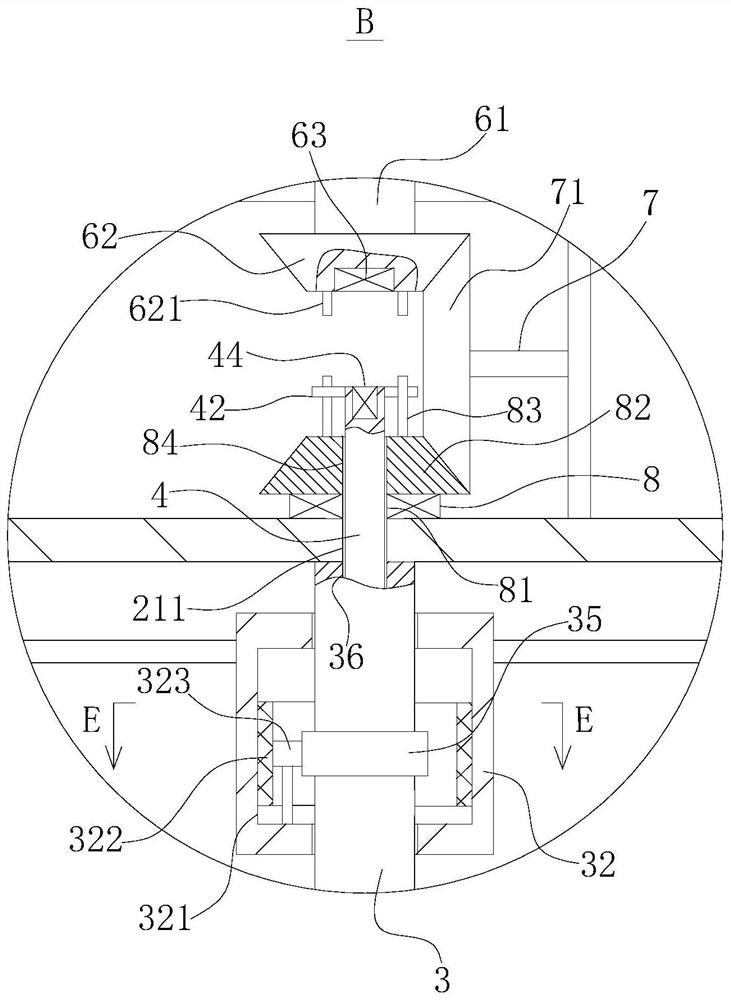

[0064] like Figures 1 to 6 As shown, a fish meal cooking and pulverizing device includes a cylinder body 1, a mixing cylinder 2, an electric heating tube 111, a stirring mechanism, a driving mechanism, a mincing mechanism and an extrusion mechanism.

[0065] The cylinder body 1 is provided with a cavity 11, the top of the cylinder body 1 is fixedly connected with a feeding pipe 12, the bottom of the cylinder body 1 is provided with a discharge hole 14, and the upper edge of the outer side wall of the cylinder body 1 is Several supporting legs 16 are provided in the circumferential direction.

[0066] The mixing drum 2 is coaxially fixed in the cavity 11. The mixing drum 2 is sequentially connected with a first straight cylindrical portion 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com