Reaction kettle for coating processing

A technology of reaction kettle and reaction kettle body, which is applied in the field of reaction kettles for coating processing, can solve the problems of low catalytic efficiency and achieve the effects of sufficient heating, energy saving and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

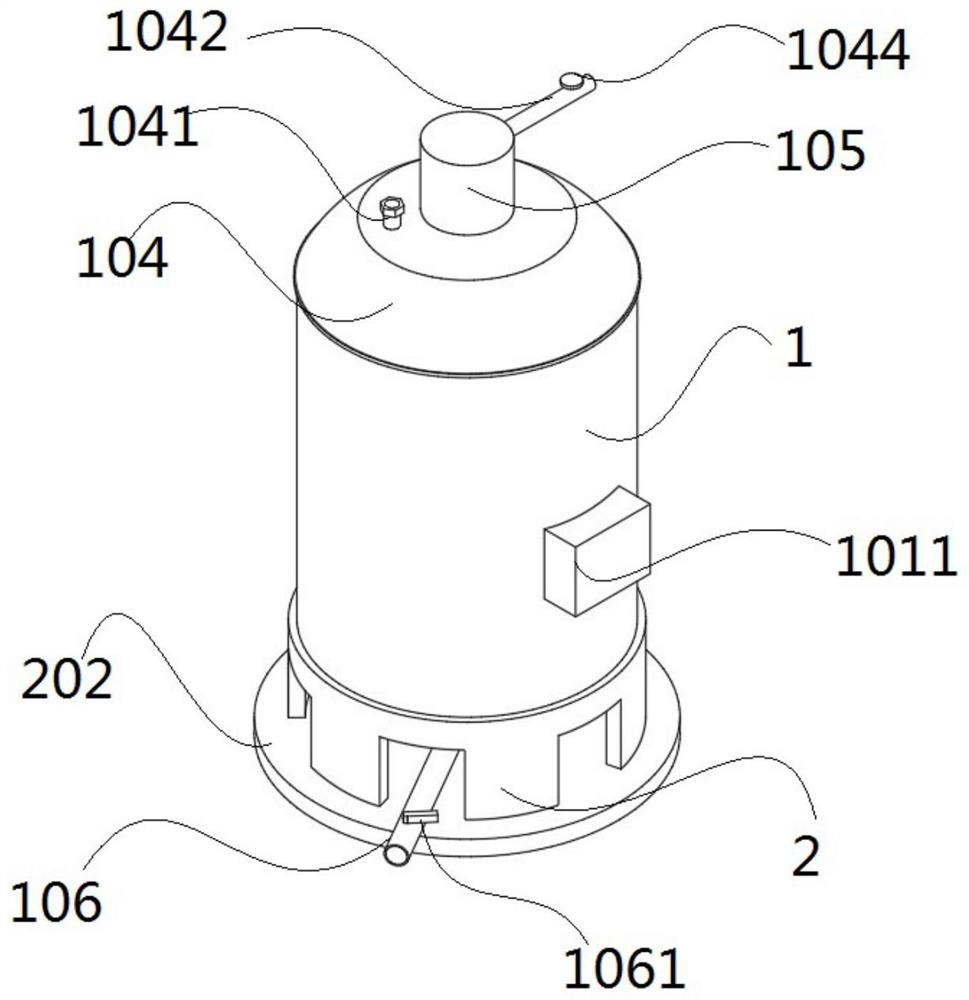

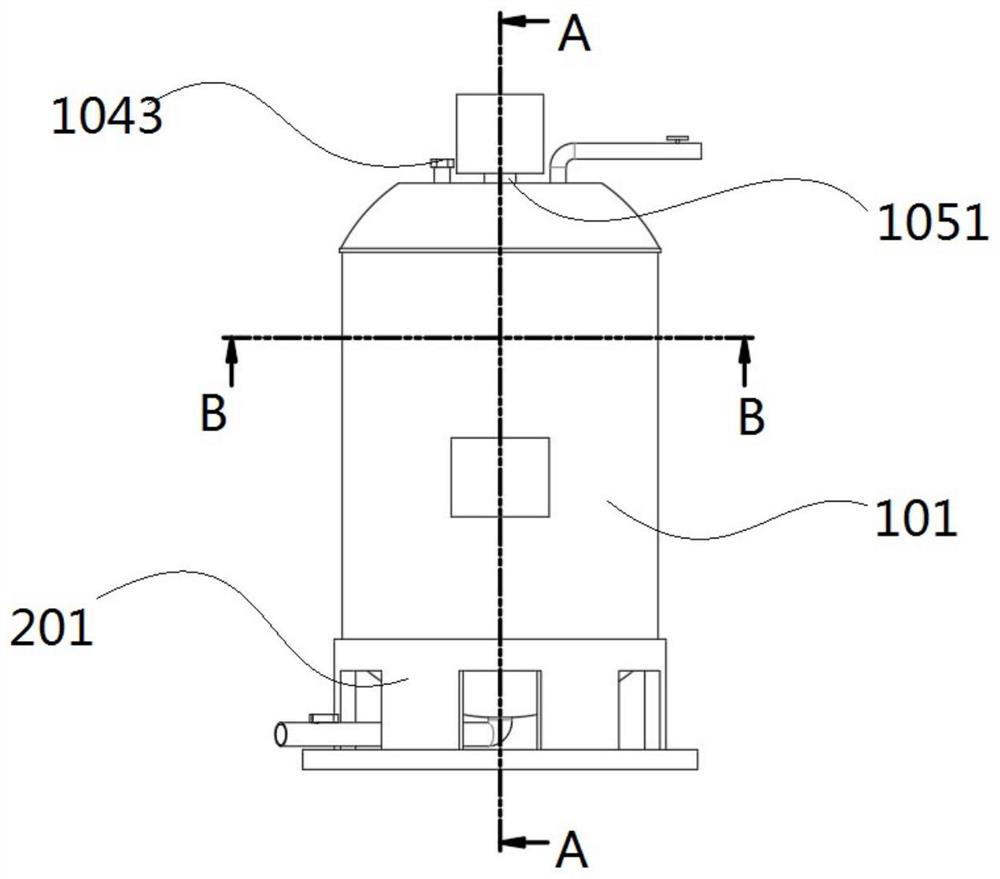

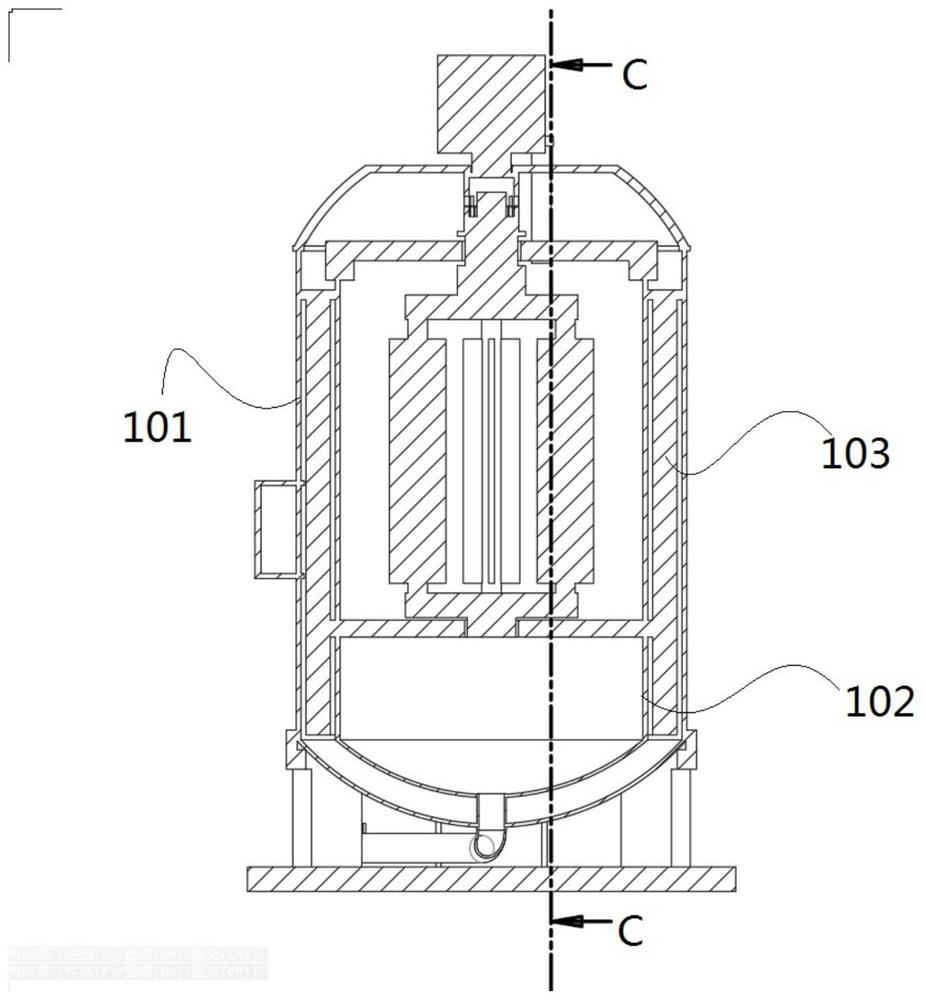

[0042] see Figure 1-6 As shown, the present embodiment is a reaction kettle for coating processing:

[0043] The model of the stirring motor 105 involved in the present invention is a YS three-phase asynchronous motor; the model of the electric heating cover 103 is a JX021 combined ceramic electric heating ring;

[0044] When using the reaction kettle of the present invention, at first each electrical component is connected with an external power supply, the material to be processed is injected into the reaction tank 102 through the feed pipe 1041, and the electric heating jacket 103 and the stirring motor 105 are turned on to make the material in the reaction tank Fully react in 102 by means of heating and stirring. After the reaction is complete, close the electrical components, open the discharge valve 1061, and discharge the material to the next production process;

[0045] After the discharge is completed, connect the cleaning pipeline 1042 to a water source, open the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com