Processing method of organic fertilizer

A processing method and technology of organic chemical fertilizers, applied in the direction of organic fertilizers, inorganic fertilizers, potash fertilizers, etc., can solve the problems of large fertilizer nutrient loss and poor soil improvement effect, and achieve the effect of improving fertilizer efficiency, improving fermentation effect, and significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

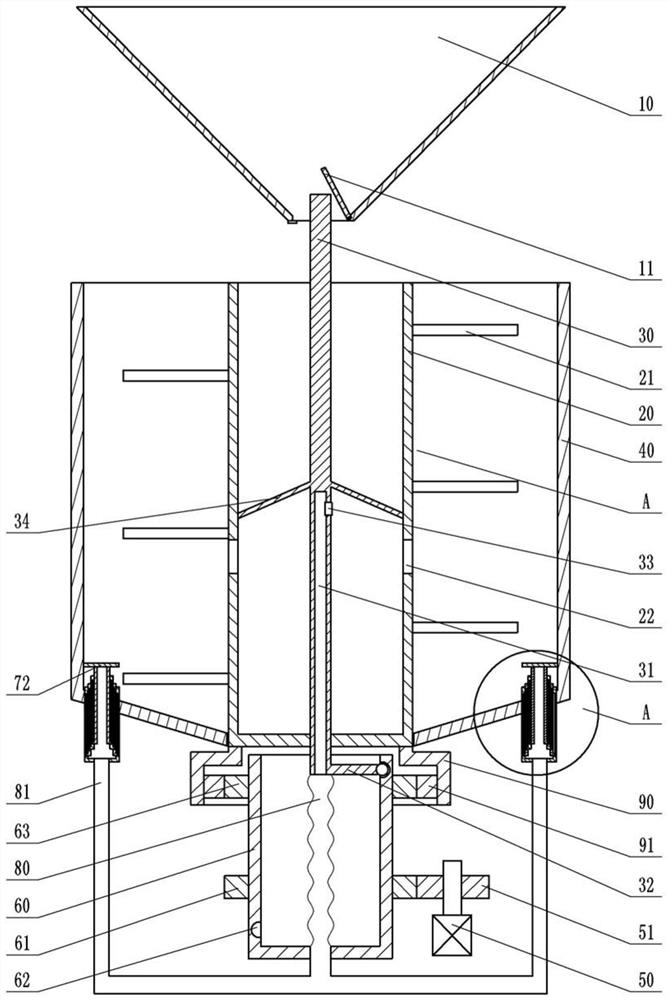

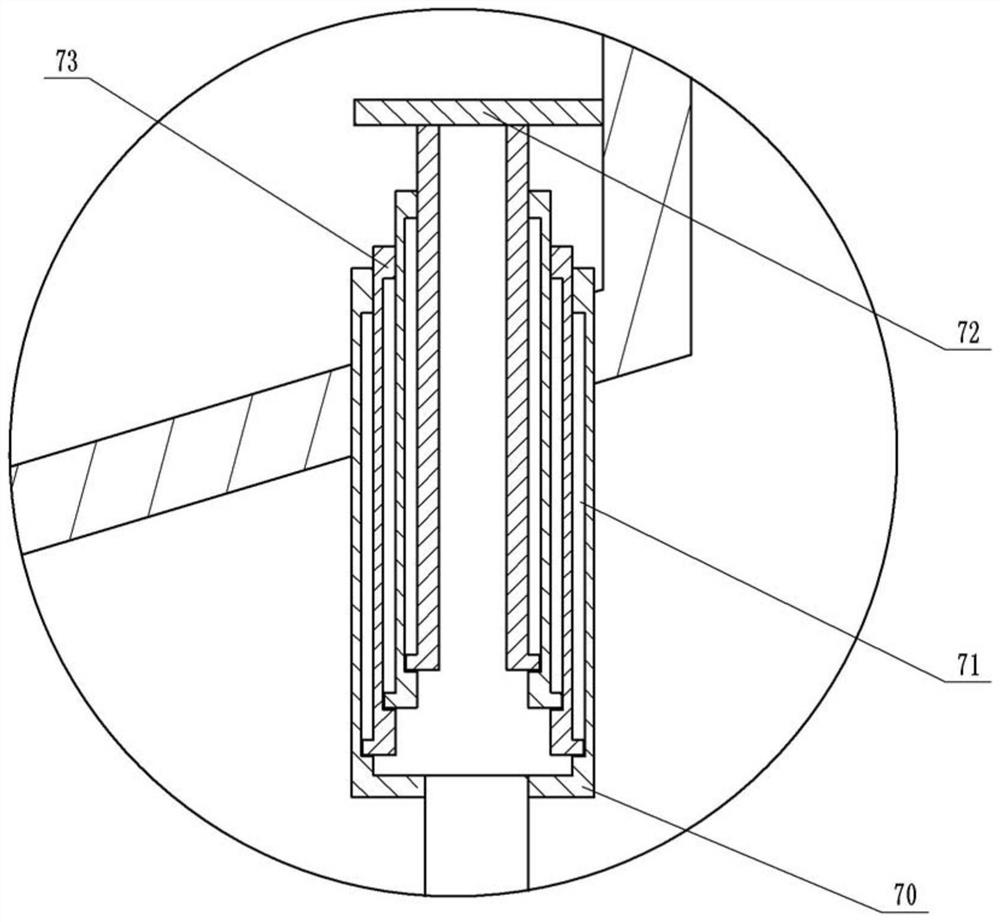

Image

Examples

Embodiment 1

[0027] The present embodiment discloses the processing method of organic chemical fertilizer, comprises the following steps:

[0028] (1) Prepare the following raw materials in parts by mass: 110 parts of cow dung, 52 parts of chicken manure, 15 parts of strain liquid, 42 parts of pond mud, 56 parts of wheat bran, 26 parts of sawdust, and 45 parts of slow-release fertilizer. Wherein the preparation of the strain liquid comprises the following steps: a, batching, preparing the following raw materials in parts by mass, 13 parts of anaerobic strains and 100 parts of water; b, mixing the anaerobic strains with water evenly to obtain the strain liquid, wherein The anaerobic strain used was sludge fermentation bacteria C3008 / SLW purchased from Paul Timhan (Weifang) Biotechnology Co., Ltd. Wherein the preparation of slow release fertilizer comprises the following steps: a, batching, prepare the raw material of following mass parts, 64 parts of perlite, 11 parts of ammonium phosphate,...

Embodiment 2

[0041] The present embodiment discloses the processing method of organic chemical fertilizer, comprises the following steps:

[0042] (1) Prepare the following raw materials in parts by mass: 118 parts of cow dung, 45 parts of chicken manure, 16 parts of strain liquid, 39 parts of pond mud, 60 parts of wheat bran, 22 parts of sawdust, and 44 parts of slow-release fertilizer. The preparation of the strain liquid includes the following steps: a. batching, preparing the following raw materials in parts by mass, 14 parts of anaerobic strains and 108 parts of water; b. uniformly mixing the anaerobic strains and water to obtain the strain liquid. Wherein the preparation of slow release fertilizer comprises the following steps: a, batching, prepare the raw material of following mass parts, 68 parts of perlite, 10 parts of ammonium phosphate, 10 parts of potassium sulfate, 8 parts of urea; B, mix ammonium phosphate, potassium sulfate and Dissolving urea in water to prepare a mixed sol...

Embodiment 3

[0049] The present embodiment discloses the processing method of organic chemical fertilizer, comprises the following steps:

[0050] (1) Prepare the following raw materials in parts by mass: 114 parts of cow dung, 57 parts of chicken manure, 18 parts of strain liquid, 48 parts of pond mud, 52 parts of wheat bran, 24 parts of sawdust, and 40 parts of slow-release fertilizer. The preparation of the strain liquid includes the following steps: a. batching, preparing the following raw materials in parts by mass, 15 parts of anaerobic strains and 100 parts of water; b. uniformly mixing the anaerobic strains and water to obtain the strain liquid. Wherein the preparation of slow release fertilizer comprises the following steps: a, batching, prepare the raw material of following mass parts, 64 parts of perlite, 18 parts of ammonium phosphate, 7 parts of potassium sulfate, 10 parts of urea; B, mix ammonium phosphate, potassium sulfate and Dissolving urea in water to prepare a mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com